A new sub-contract profiling business has launched in County Durham with a clear focus on precision, flexibility and fast turnaround. Waterjet-Tec Ltd, founded by experienced industry professionals Terry Stewart and Peter Robinson, has invested in a twin-head Optima O-Series 420 waterjet cutting machine from Rochdale-based

Kerf Developments.

The company is located close to its sister business, Laser Profiling (North East) Ltd, and was established following the closure of a local waterjet cutting firm. Mr Robinson explained: “We previously sold a business and I had retired. But a gap in the market for a sub-contract waterjet business appeared and it was too good to pass up. We found a facility, looked for a machine and employed experienced staff.”

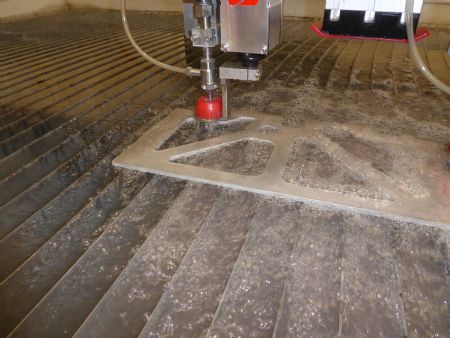

With decades of experience in the sheetmetal and profiling sectors, the co-directors brought in two engineers with specialist knowledge of waterjet cutting. Terry Stewart added: “We identified a market opportunity around two core points. Firstly, there was an opportunity for cutting a wide range of non-metallic materials beyond the traditional laser and plasma remit. Secondly, certain parts across industries such as aerospace, offshore and the military require cutting with no heat generation, as it has a propensity to alter the physical properties and integrity of components.”

Speed and flexibilityAs a start-up, the company’s first machine would be critical to its reputation and growth. The directors sought a solution that could deliver both speed and flexibility, with a strong emphasis on reliability and service support. Mr Robinson continued: “We have decades of waterjet, laser and plasma cutting experience, and what has been a major let down is spares, consumables and service support. However, Kerf has been the stand-out supplier. Its Rochdale headquarters stocks an abundance of spare parts and consumables, so same or next-day service is always assured. In contrast, other vendors have to ship parts from Europe. This often takes at least three days to arrive, and then you have to wait for an engineer to install parts — the situation isn’t much better with consumables.”

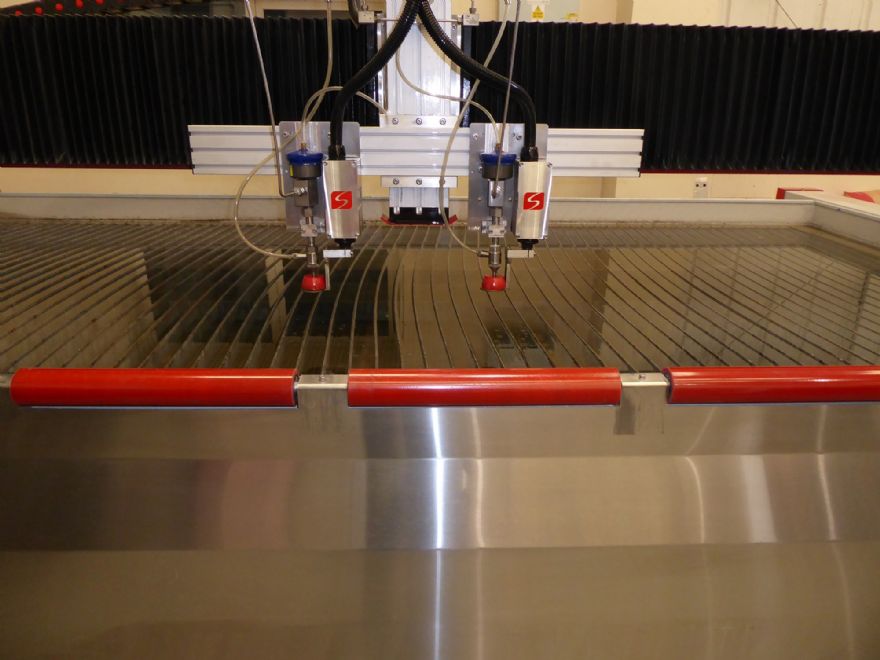

After a thorough evaluation of the market, Waterjet-Tec selected the Optima O-Series 420, a 4 x 2m bed machine equipped with two cutting heads. Mr Robinson explained: “Despite looking at rival machines, we knew the Kerf machine would be at least 30% faster than anything else, giving us a competitive edge as soon as we opened the doors for business. Our team also had first-hand service experience from numerous waterjet suppliers, and they immediately recommended Kerf.”

Installed in April, the Optima 420 is powered by two BFT ECOTRON high-pressure pumps, each capable of generating up to 4000bar. The system includes a hydraulic intensifier pump with a built-in booster and fan cooler, enabling the machine to cut a wide range of materials up to 200mm thick with high precision and repeatability.

Mr Stewart said: “There are some high-profile Ministry of Defence (MoD) and offshore projects that can only be cut with waterjet due to the strict limitations on heat-transfer during processing. With the twin-head capability, we can cut double the number of parts that our competitors can achieve. This instantly makes us more cost competitive with the bonus of significantly reduced lead times. Our turnaround times can be days, not weeks like competitors, especially on large parts.”

The robust construction of the Optima 420 has also proven beneficial. Mr Robinson added: “We are currently profiling large nylon pipes, and these heavy-duty parts need a stable cutting environment. The machine has a robust steel frame that withstands excessive weight and vibration and accommodates all of our large parts.”

The machine’s bridge design features twin-sided drives and digital AC servos on each axis, providing a rigid CNC platform capable of 20m/min rapid acceleration. A 40mm diameter ballscrew drive further enhances stability and precision.

Twin-head capability is a gamechangerWaterjet-Tec is already exploring lights-out manufacturing. Mr Robinson continued: “We are extremely competitive on both price and turnround times due to the twin-head capability. We are even scheduling work to load the machine at the end of a shift to run lights-out. Depending on the job, the machine will run for 10 to 20hr unmanned, and the next step is to look into fitting cameras on the machine. This will help us to monitor, reload and run the Optima for even longer unmanned periods over evenings and weekends.”

The company has also benefited from the intuitive CNC control system and IGEMS CAD/CAM nesting software supplied with the machine. Mr Stewart explained: “The IGEMS system is straightforward to use. It makes programming parts extremely fast and efficient, so we can create programmes while the machine is running. For customers who supply drawings as .STEP and .IGES files, we can add toolpaths, calculate machining times and turnround quotes for customers in minutes. This gives us a massive advantage over competitors and sets us apart. Additionally, the nesting technology minimises material waste and costs whilst the speed and contours of cutting paths are also optimised to streamline production and minimise non-cutting times.”

Support from Kerf has extended beyond hardware. Mr Stewart continued: “Like the availability of spares, consumables and any other support we need, Kerf are always available to help us with the software. However, the IGEMS suite is very intuitive, and if we do have any challenges, they have a complete library of online video tutorials where we can upskill ourselves.”

Reflecting on the company’s early success, Mr Robinson concluded: “We are delighted with everything that Kerf has supplied. From the initial discussions to commissioning and ongoing support and consumables, Kerf has proven to be a partner on this journey, supporting us at every step. As for the machine, we fully expect the Optima 420 to have a very short payback period, and our annual turnover will be approaching £1 million in the near future, which is a fantastic foundation for a new business to grow.”