HydraForce

HydraForce is the world’s largest supplier of high-performance hydraulic cartridge valves, electro-hydraulic valves, custom manifolds and electro-hydraulic controls. Global sectors served by the business include the demanding material-handling, agriculture, fluid power, construction and mining industries.

The challenging nature of HydraForce’s customer base means that it applies industry-leading quality standards in all of its global manufacturing sites.

Located in the Advanced Manufacturing Hub in Aston, Birmingham, HydraForce Hydraulics Ltd is the European headquarters of HydraForce Hydraulics Inc, USA. To ensure that HydraForce, Birmingham upholds the company’s hard-won reputation for the quality and durability of its products, regular investments are made in advanced quality-control equipment.

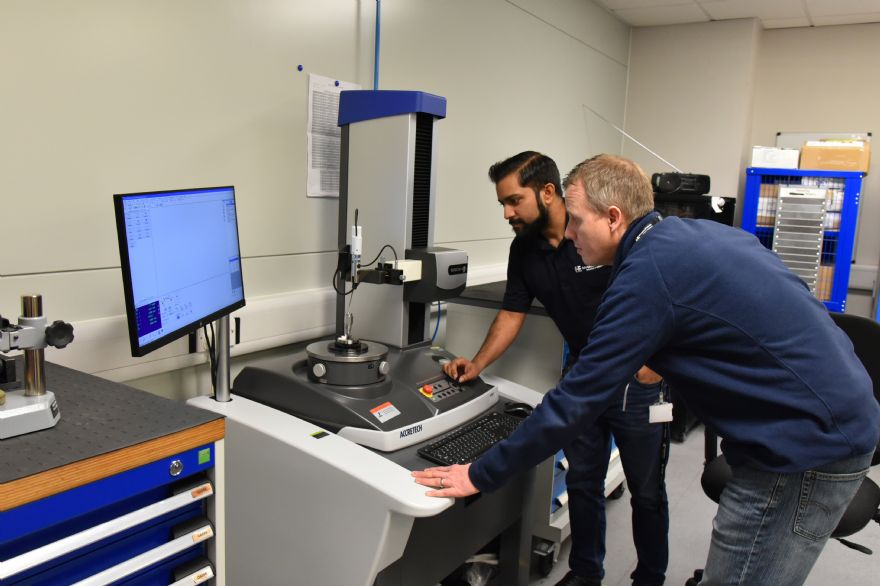

The most recent addition to HydraForce Birmingham’s collection of high-precision measuring aids is an advanced Accretech RONDCOM NEX roundness and form measuring instrument that was supplied by Cambridge-based

Zeiss UK.

Explaining the reason for the RONDCOM NEX purchase, Ali Mohammed, HydraForce Birmingham’s European quality/warranty manager, said: “We manufacture a comprehensive line of high-quality hydraulic valves and manifold systems. Our products meet global quality standards including ISO 9001 and QS 9000.

“To confirm that they perform beyond industry standards, our hydraulic products go through rigorous testing and inspection routines. Also, to ensure global consistency, the teams at HydraForce plants in North America, Brazil, Asia, and here at our European headquarters in Birmingham, follow the same manufacturing processes and standards.

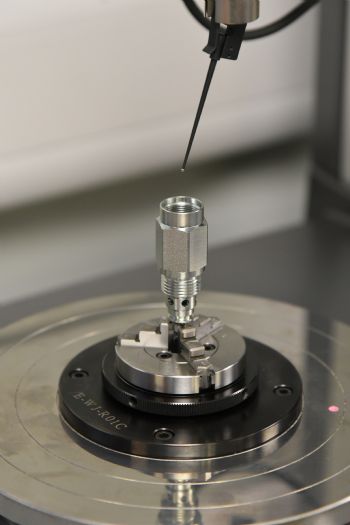

“The bores in the high-precision hydraulic manifolds manufactured by HydraForce Birmingham have extremely challenging geometrical tolerances. Parameters checked include roundness, roughness, cylinder form, perpendicularity, parallelism, straightness, flatness, coaxiality and concentricity. All of these attributes need to be inspected to an extremely high degree of accuracy.

“We have recently increased the number of European suppliers we deal with and reduced the amount components we import from our US plant. As all of the parts previously sent from our North American operation arrived in a fully inspected condition, to enable all brought-in European components to be 100% inspected we needed to increase our quality control capacity in the critical area of highly precise bore geometry measurement.”

He continued: “This situation was further compounded as we have recently considerably increased our bore honing capacity. To help overcome these potential difficulties I searched for a suitably accurate and efficient profile measuring instrument. Having studied the available models from three leading metrology manufacturers I came to the decision that Accretech’s advanced RONDCOM NEX CNC instrument was the most capable option.

“In addition to the precision of our measuring equipment being important, given the high-volume of components now passing through our busy inspection department, the speed and ease of use of our quality control equipment is also crucial to the department’s efficient operation.

“Therefore, it helped my profile measuring instrument decision that, in addition to delivering the required high-precision standards, the RONDCOM NEX’s rapid, fully automated CNC measuring procedures provided the desired operational efficiency standards.”

High-precision capabilitiesMr Ali added: “As the RONDCOM NEX is relatively easy to operate, following operator training, our new Accretech profile measuring instrument soon proved its high-precision capabilities across all bore parameters.

“As we are now able to quickly recall pre-written programs and start fast, highly accurate bore inspection routines, our RONDCOM NEX is now making a significant contribution to the efficient operation of our quality department.”

A

ccretech products, integrate seamlessly into the renowned range of industrial measuring technology offered by ZEISS UK. When challenged with HydraForce Birmingham’s demanding precision and efficient operating criteria, the staff of ZEISS UK were confident that the recently launched RONDCOM NEX would provide the ideal metrology solution.

In addition to other innovative facilities, the advanced RONDCOM NEX boasts an axis speed potentiometer, an automatic force detector and automatic centring and tilt correction, making all precision measuring routines considerably more efficient.

The Accretech CNC instrument provides the best concentricity and straightness precision figures in its class — (0.02+3.2H/10000)µm and 0.15µm (Z300) respectively. These advantages are made possible by the extremely high rotational accuracy of the instruments’ air-bearing based rotary tables. The RONDCOM NEX Rs variant also enables highly accurate roughness measurements, as per DIN EN ISO, in linear R and X direction, also in rotational directions on workpiece circumferences.

The flexible RONDCOM NEX series’ design enables the high-precision measurement of form, diameter and surface simultaneously. The modular nature of the new form measuring instruments means that they are available in a wide range of variants, ensuring that customers can now specify a system that will be configured exactly to their individual requirements.

Future proofAccretech’s creative ‘building-block’ approach means that RONDCOM NEX series instruments remain future proof. For example, in addition to undertaking today’s precision measuring tasks, if users’ requirements change, all models can be easily adapted to suit changing needs.

Similarly, new Accretech instruments can be purchased as manual systems, then later converted to CNC operation if a higher degree of automation as required. CNC add-ons include positioning tables with several asymmetrical measuring positions to accommodate complex workpieces. Also, pallet clamping capability for components being inspected in large batch sizes.

Tim Wood, Accretech SBS regional director North Europe, concluded: “The recent sale of an advanced RONDCOM NEX form tester to HydraForce, Birmingham helps to illustrate the synergy between the high-precision products of ZEISS Industrial Metrology and Birmingham-based

Accretech SBS and typifies the successful cooperation between the businesses.

“The staff of Accretech SBS were happy to support ZEISS by performing an efficient installation at HydraForce Birmingham and by ensuring that comprehensive operator training took place.”