Amorphology

Amorphology, a

NASA spin-off company, is a leader in the application of advanced materials and manufacturing technologies for the improvement of non-lubricated micro-gears for robotics and other industrial applications using innovative ‘amorphous’ metals (formed by ‘shock freezing’) such as ‘bulk metallic glasses’.

These materials have ‘advanced features’ compared with steel, titanium and aluminium, for example, and the company’s patents (for several metal alloys) are based on developing gears for space and other extreme-cold-temperature applications.

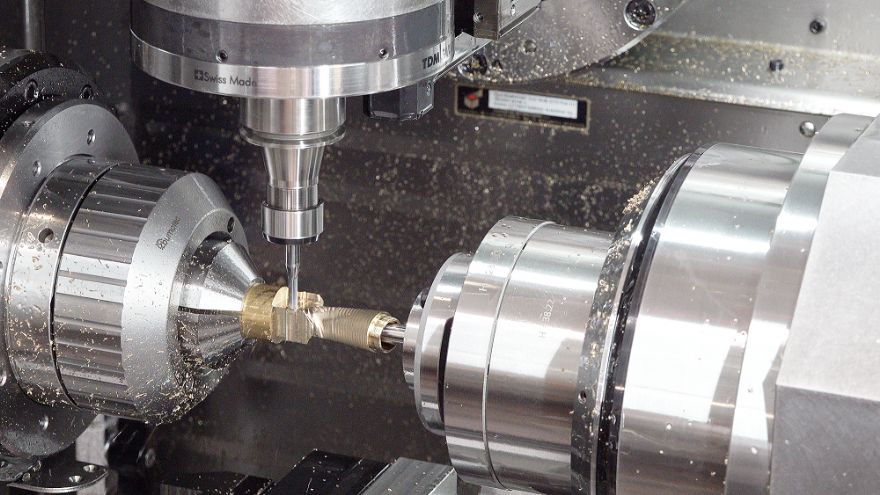

Amorphous metals are a non-crystalline class of alloys that ‘cut and chip’ differently to other materials and, in the company’s quest to source a machine that could produce the micro-gears, it conducted machining tests with several machine suppliers to assess the precision, cycle times and overall capabilities of the machines.

Amorphology’s COO Jason Riley said: “We were focused on finding the best machine to meet our rapid prototyping, mould insert cutting and post-processing needs. The Starrag Bumotec s191H mill-turn machining centre outperformed all contenders.”

After receiving CAD files of the prototype micro-gears and undertaking tests using a Starrag-developed cutting tool at the machine tool builder’s sites in Switzerland and the USA, several batches of samples were produced (Starrag has a UK subsidiary in Birmingham —

Starrag UK Ltd).

Amorphology was impressed with the results; and following discussions with Starrag about how both companies could co-operate to grow their respective businesses, it was agreed that Amorphology would showcase the Bumotec machine in its Pasadena (California) site for both companies’ customers to view.

Mr Riley added: “Amorphology is set to make a wide variety of parts on the machine, from mould inserts to prototype gears, as well as other production bulk metallic glasses and traditional metal parts. We are targeting high-precision parts with tolerances of often around 5µm on certain dimensions.

“Most of our work is focused on rapid prototyping and relatively low batch production quantities in the region of 100s of parts per month. The Bumotec provides the mill-turn capabilities that we currently don't have, as well as a higher production capacity; it supplements our current abilities and it provides capabilities that we didn’t previously have.”

The s191H has a 65mm bar capacity, a bar feed system, high-pressure (3 HP) coolant, a work envelope of 410 x 200 x 400mm, linear drives and offers a high level of thermal stability.

Moreover, it is accurate to ±2.5µm, has a main spindle that is complemented by a sub-spindle that can turn in both horizontal and vertical planes, for multi-process/tasking routines, tool magazine options that extend to up to 90 pockets, rapid traverse rates of 50m/min and a 30,000rev/min spindle speed (40,000rev/min is also an option).