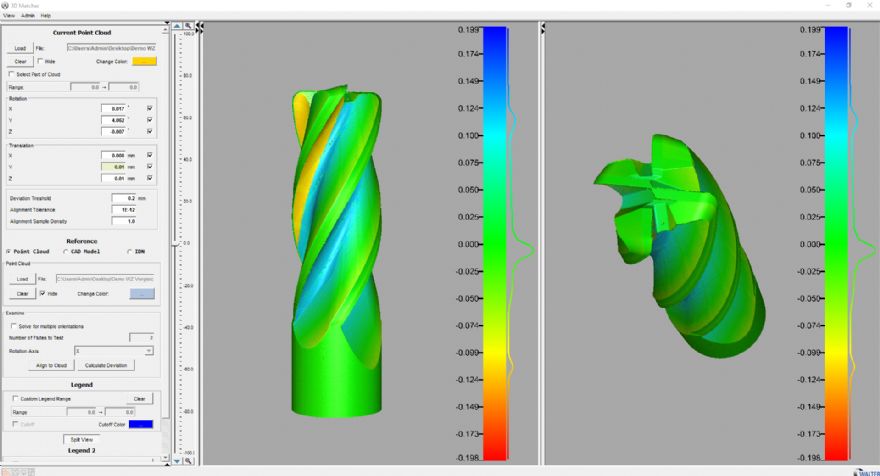

Screen shot shows a scan of the tool after it has been ‘viewed’ by the 3-D sensor (shown below)

Screen shot shows a scan of the tool after it has been ‘viewed’ by the 3-D sensor (shown below)Warwick-based

Walter Ewag UK has announced a ‘step change’ in the fully automatic measurement and digitalisation of tools with the launch of the Walter 3-D laser sensor that enables the Walter Helicheck Pro and Plus tool measurement machines to scan at four-times the resolution than previously, and to process that data four-times faster.

Ideal for inspecting high-performance tools as used in industries such as automotive, aerospace and medical, where cutting edge geometry, pitch and spiral pitch vary widely, the 3-D sensor could replace two separate machines traditionally used for measuring such tools — perhaps a combination of conventional and laser checking.

Available as an option on the Helicheck Pro and Plus machines and their corresponding ‘Long’ versions – which can accommodate tools up to 80mm diameter and 605mm long — the 3-D sensor has swivel angle ranges from -55deg to 90deg to also enable the complete scan of indexable inserts.

Easily and quickly programmed using a routine wizard, with resulting short set-up times, the 3-D sensor effectively ‘visualises’ the workpiece as a point cloud (in differing formats) and enables various measurements to be undertaken on the three-dimensional image.

When the resulting image is ‘placed’ on the tool’s three-dimensional design drawings, or a master part, any deviations can be clearly seen (via the integrated 3-D viewer) as three-dimensional comparisons of point cloud and target model, including surface reconstruction.

The result, according to Walter Ewag, is that tool measurement is now more accurate and faster than ever before.