Rochdale-based Volz Engineering Ltd, a wholly-owned subsidiary of

Volz Filters UK, has been supplied with two Fanuc-controlled multi-tasking machine tools by

Mills CNC, the exclusive distributor of Doosan machine tools in the UK and Ireland.

The machines — a compact 8in chuck Lynx 2100LSY turning centre, equipped with a sub-spindle, Y-axis and driven tooling, and a five-axis DVF 5000 machining centre supplied with an 18,000rev/min spindle and a 120-tool position automatic tool changer — were installed at the company’s 10,000ft

2 facility in December 2021 and February 2022, respectively.

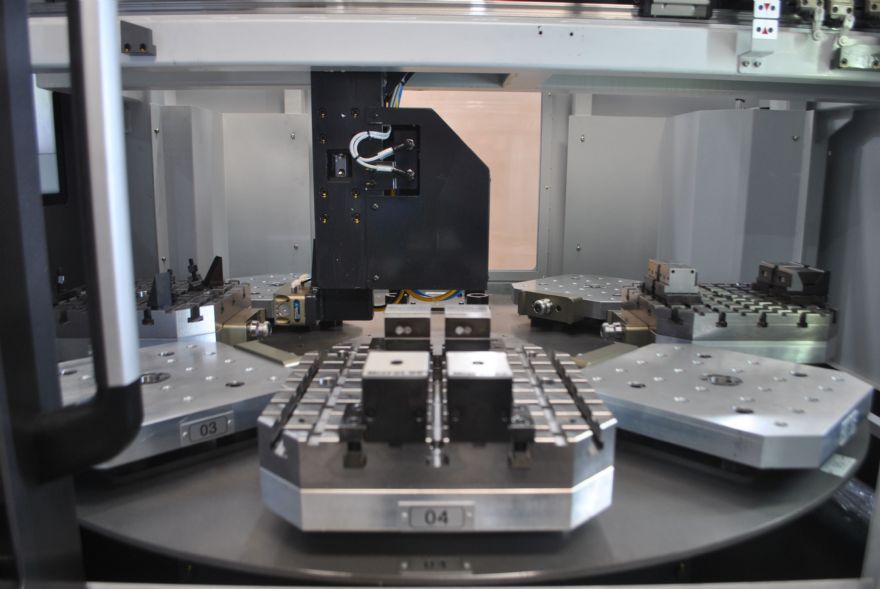

To increase the productivity potential of each multi-axis machine still further, Volz Engineering specified a Hydrafeed Multifeed 65 short magazine bar loader (to be integrated with the Lynx lathe), and a Doosan (eight-pallet station) automatic workpiece changer (AWC), to be integrated with the DVF 5000 machine.

Managing director Alan Reeson said: “As part of our ambitious growth strategy we have recently rationalised and re-focused the scope and scale of our operations; divesting low-growth and less profitable business activities in favour of ones that offer a better growth trajectory and a more favourable return on investment.”

As a result, Volz Engineering will continue to produce high-quality components (filter frames and strips) for its parent company, as well as the design, development and manufacture of specialised, application-specific automated filtration production machines.

In addition to focusing on these ‘core’ business activities, the company has also made the decision to create a new precision sub-contract machining operation at its facility, to offer customers fast turnround high-quality machined components.

Mr Reeson continued: “The danger, when setting up any sub-contract machining operation, is to lack focus and attempt to try and be ‘all things to all people’. This approach invariably means that you can end up chasing your tail and are tied up dealing with unprofitable work.

“For our operation we have adopted a different route and implemented a ‘sniper’ strategy, targeting those sectors and specific companies, where we know we can provide real value and develop long-term, mutually profitable relationships.”

Prior to launching its new precision sub-contract machining operation, the company did its homework and spent significant time and resources creating a robust and comprehensive business plan.

Mr Reeson explained: “By researching the market and understanding customer needs and requirements, as well as competitor strengths and weaknesses, we have been able to create differentiation in the market based on quality, service and reliability, and cost-competitiveness.”

The scope and scale of Volz Engineering’s sub-contract machining operations determined, in part, by its market research activities and combined with the significant experience and expertise of key members of staff, are focused on the milling and turning of complex, precision parts, made from a range of materials, and characterised by their tight geometric tolerances and high surface finish requirements.

The focus, again determined by market demand and business opportunities, but also conditioned by the physical space available at Volz Engineering’s existing facility, is on milled parts (typical dimensions up to 500 x 500mm) and turned parts (typical diameter up to 65mm).

Operations director James Alletson said: “Like every company we have limited space available. In setting up our precision subcontract machining operation we clearly had to keep in mind these limitations as well as the footprints of the new equipment we required.

“Another aspect of our sub-contract service was on our ability to machine one-offs and prototypes, through to pre-production parts and low- to medium-volume batch series.”

Improving workflowMr Alletson continued: “Our facility needed to be significantly upgraded in order to meet our immediate and future needs. In addition to improving the power and air supply and overhead lighting, we also spent time reorganising the factory floor to optimise the workspace available and to improve workflow.

“Creating dedicated ‘zones’ for filter component production and for the design and assembly of our specialised automated filtration production machines freed-up much needed space for the new sub-contract machining operation.”

Mr Alletson added: “While there are no doubt some excellent used machine tools on the market, we decided, from a reliability and performance perspective, that our new precision sub-contract service would have new machines and equipment at its disposal.

“Because we want to break into, consolidate and grow our position in advanced, hi-tech markets (including automotive, aerospace and defence), it was important, from the outset, that we created a favourable impression with customers.

“New machines don’t just look the part, they are also less prone to breakdowns, inspire confidence with customers that you can meet their expectations, and signify to customers and internal staff the commitment to the new venture.”

Senior managers at Volz Engineering decided, early on in the process, that the new machine tools they required for the sub-contract machining operation would be Doosan machines as they have a reputation for quality, value and reliability, and are sold and supported in the UK and Ireland by Mills CNC.

Mr Alletson explained: “A number of staff had gained experience operating and programming Doosan machine tools from previous employment. They liked the machines, were familiar with the controls and the machines’ layout and configuration, and also recognised and appreciated the strength of the pre-and after-sales service and support provided by Mills CNC.

The 8in chuck/65mm bar diameter Lynx 2100LS, with its 300mm maximum turning diameter and 510mm maximum turning length, is equipped with a 15kw/45,000rev/min spindle and a 12-station turret. The machine is fast (up to 36m/min rapids), and flexible (6,000rev/min driven tooling capability and 105mm Y-axis and a 5in chuck sub-spindle (6,000rev/min).

Meanwhile, the five-axis DVF 5000 machining centre is equally versatile and productive and is equipped with an 18,000rev/min spindle and a 120-position ATC. The machine features integrated thermal compensation, boasts 40m/min rapid rates and has a 500mm diameter table with a 400kg maximum table load.

Competitive advantageMr Alletson said: “Multi-axis and multi-tasking machines, like the Lynx 2100LSY and DVF 5000, are critically important if you want to reduce set-up and part cycle times. The ability to machine parts to completion in a single set up improves productivity and operational efficiencies and delivers a real competitive advantage.

“As a relative newcomer onto the sub-contract machining stage, so to speak, we simply couldn’t be seen as a ‘me too’ supplier. Instead, the investment in multi-axis machines, enabled us to differentiate ourselves in a cluttered market, and deliver real, tangible and provable benefits to customers.”

Right from the outset the focus for Volz Engineering, was on increasing the productivity, and improving the performance of the machine tools being acquired, by investing in automation systems. These systems would help improve operational efficiencies, reduce the cost per part and enable tight lead times to be fulfilled.

Mr Reeson explained: “Automating our new machining processes was a priority for us and was a no brainer. We recognised that an ability to run the machines unattended, overnight and over the weekends, would give us a distinct competitive advantage over many of our competitors. There seemed little point in investing in advanced machine tool technologies (like the Lynx 2100LSY and the DVF 5000), only to have them sitting idle for a considerable period of time every week.”

In just a few months almost the entire turning capacity provided by the new Lynx 2100LSY investment has been taken by an automotive customer. This has resulted in the company making an investment in a second multi-tasking Lynx lathe – a larger 10in chuck Lynx 2600SY with an MSV 80 bar feeder.

Mr Reeson concluded: “The Doosan DVF 5000 equipped with a powerful spindle, a large ATC, Renishaw probing, thermal compensation and an efficient swarf management system, and featuring the eight-station workpiece pallet changer, is built for reliable unattended, lights-out operation. The machine is proving instrumental in helping us make serious inroads into the aerospace and defence component manufacturing markets.”