Farnborough-based

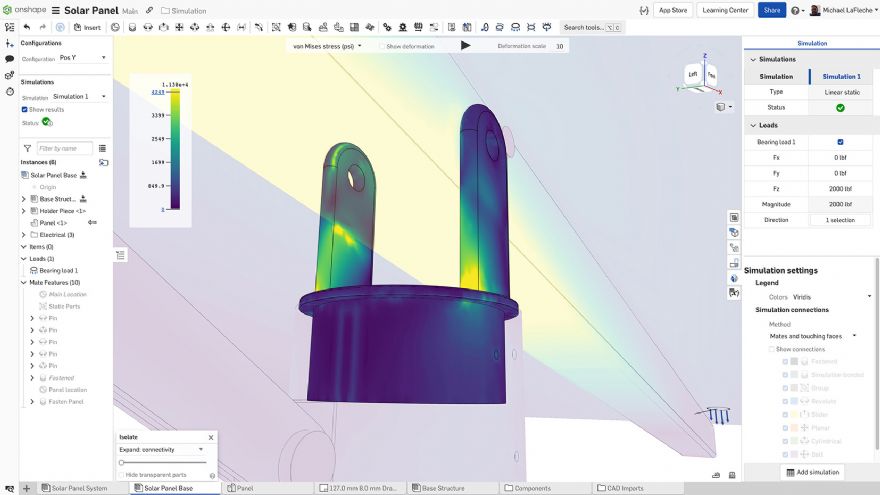

PTC has announced the availability of cloud-native simulation as part of its Onshape product development platform, which enables designers and engineers to perform finite element analysis (FEA) in a fast and simple way, as well as make informed design decisions with structural analysis throughout the product development process.

Onshape Simulation is the only computer-aided design (CAD) and product data management (PDM) tool to offer simulation that is interwoven with the core design and assembly environment, which helps reduce the time, effort, and workflows required to set up and calculate structural analysis.

Greg Brown, vice president of Onshape product management, said: “This is the first time that CAD, PDM, and simulation have all been unified in one cloud-native environment, which is an extremely efficient way for designers to simulate full assemblies, helping them make important time, material, and quality decisions earlier in the design process.”

Features and benefits of Onshape Simulation include: designers receive accurate mechanical guidance, such as strength and rigidity, without ever leaving the design environment — the CAD model and the simulation model are the same definition, which dramatically simplifies the assembly set-up for simulation; Onshape uses the existing assembly mates in the definition of the part-to-part interactions, eliminating the need to defeature, simplify, or set up connections for their models before running simulations; explore design variations quickly by simultaneously designing and analysing assemblies with no pre-processing or meshing required — simulation results are automatically refreshed when changes are made to Onshape models; as part of an Onshape document, simulations are version-controlled with built-in PDM – including simulations for all design variations – and can be shared instantly with other users for simple collaboration and decision making; Cloud computing allows simulations to be conducted fast and interactively, with no need for specialised local hardware.

Simulation is available now for Onshape Enterprise users, with availability for Onshape Professional users to follow shortly.