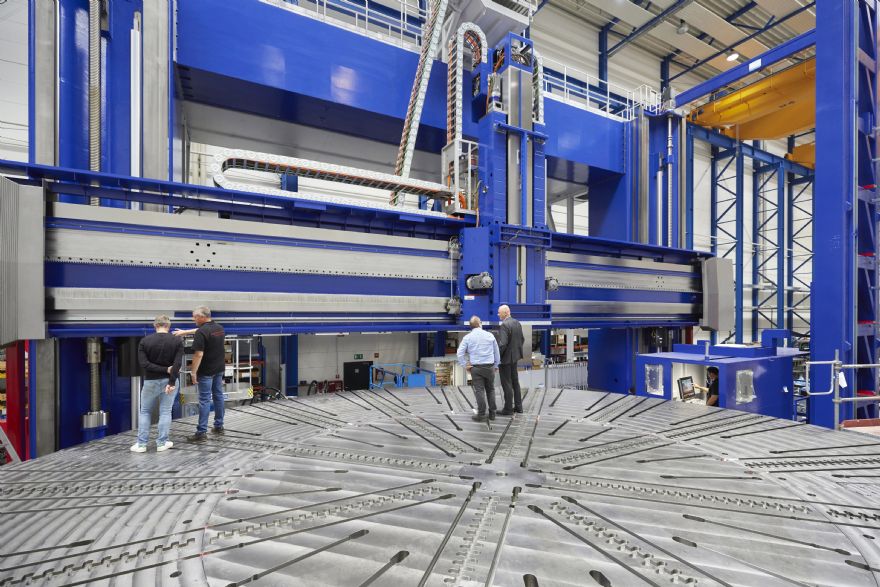

One of Haco’s new gantry portal milling machine which will allow for effective and efficient turning, milling and drilling of even very large parts made from high-strength welded and cast steel

One of Haco’s new gantry portal milling machine which will allow for effective and efficient turning, milling and drilling of even very large parts made from high-strength welded and cast steelDenmark-based

Haco A/S has invested in two large-capacity Droop+Rein portal-type machining centres from

Starrag to meet the rising demand for components for larger offshore wind power turbines with outputs of up to 16MWh.

Complementing the company’s existing five Dörries vertical turning and boring mills, the new machines — one focused on milling and the other as a turning machine with a third linear axis via the table — will be targeted at the complete machining of components such as rotor housings (with dia up to 10,000mm; though sizes up to 11,500mm are also now being considered), as well as front and stator sheets, brake discs and other components.

Haco’s ‘super-sizing’ of its production enhances 60 years of contract manufacturing success, in latter years especially with the Dörries machines and on wind power components having maximum turning dia on the flanges of 9,000mm.

With a clearance of 12,600mm between the portals, gantry axes travels of 14,000mm and a stroke of 3,500mm in the ram, the new 500-tonne milling-based machining centre will also undertake turning and drilling of parts made from high-strength welded steel, as well as cast steel, through the interaction of its 100kW milling head with two x 111kW master-slave main drives.

The new turning machine, with a third linear axis and an adjustable table, has similar dimensions to the milling machine but comes with an additional feature that takes into account the ever-expanding dimensions in wind power plant construction; by adjusting the table, the turning dia can be expanded from 13,000 to 15,000mm.

This machine is equipped with two x 136kW master-slave main drives and a 80kW milling head, and is predominantly designed for turning.

When it comes to wind power, Denmark is leading the way — 40% of the country’s energy requirements are fulfilled with electricity generated by wind power, and Haco’s prime customer,

Valmont SM A/S, is a world leader in the supply of steel components to the wind power sector. Haco currently processes around 10,000 tonnes of high-strength steel each year, but the wind power sector is now also increasingly looking at the use of aluminium alloys, castings and composites, so the company’s investment in the two new machines has been made with these materials in mind.

The choice of Droop+Rein machines for this significant investment was based on Haco’s long-standing experience with Starrag on machine reliability and longevity, customer service, machine price and the delivery schedule.

Up until now, Valmont has been transporting the welded blanks to Haco’s site 100km away but, with this multi-year contract now embracing larger components, the two companies have decided on a more sustainable form of collaboration which will see Haco establishing a subsidiary plant for the two new machines close to Valmont’s headquarters, close to the sea.

From here, even very large and extremely heavy rotor housings can be transported via ship in a much more environmentally-friendly way for final assembly near to the coast.