hyperMILL rest material machining: perfect transitions for a bumper mould.

hyperMILL rest material machining: perfect transitions for a bumper mould. In the mould and die industry, the hyperMILL CAD/CAM suite from Bicester-based

Open Mind Technologies UK Ltd is regarded as an end-to-end solution due to its ability to cover all areas including electrode manufacturing and wire EDM. The software package has now been enhanced even further with the introduction of a five-axis radial machining function which is ideal for the process-optimised production of round moulds where surfaces cannot undergo hand finishing or polishing operations.

For components such as blow moulds which are applied in vehicle bumper production or consumer goods bottles for instance, high quality machined surfaces are critical as secondary hand finishing can introduce optical facets and surface inconsistencies that may appear in down-stream processing.

The rise in complexity of bottle designs is also increasing the quality expectations required from blow moulds and there is a wide variety of containers that often have additional features that double up as functional elements, such as handles, decorations, and individual brand logos.

The three-axis machining of these types of moulds sometimes require very long tools and part

re-clamping to mill undercut areas. A three-axis approach also means that the point where the milling tool makes contact with the semi-circular profile varies. This can result in uneven surfaces and it is where optimised five-axis strategies can make a significant difference.

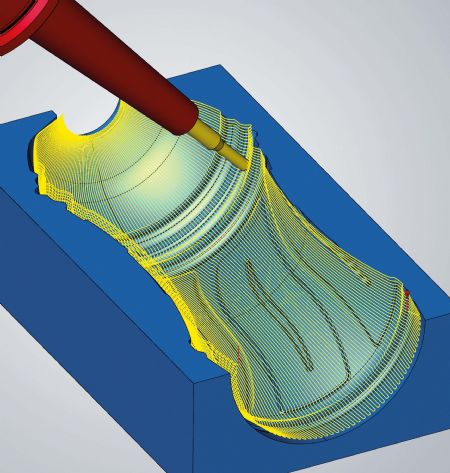

The improvements to the current version of hyperMILL combined with five-axis radial machining are setting new standards in blow mould machining (see picture below). Thanks to a radial projection method, the toolpaths are calculated extremely quickly, and the user can apply various machining strategies to respond flexibly to the component conditions. The new ‘Flow Equidistant’ infeed strategy is the first of its kind that supports the generation of toolpaths with a constant infeed for vertical and challenging surfaces.

Seamless machiningThis means that surfaces can be integrated into the overall machining sequence and processed in a single step. Seamless machining with a very high-surface quality is guaranteed. Every machining sequence needs to produce sharp corners at the junction of the upper and lower halves of the mould to avoid problems during the moulding process. An ‘Automatic Tangent Extension’ feature eliminates the manual CAD steps needed to extend the numerous surface elements found in complex designs.

For example, hyperMILL high-precision machining technologies are used in tool and mould-making to manufacture bumper segments — a highly superior surface quality is achieved using ball and barrel cutters. Two CAM technologies ensure that the various tools and positions during machining are no longer recognisable after the process has been completed. The first of these is the ‘Surface Precision Mode’, which calculates the toolpath directly on the surfaces of the CAD model.

The machining tolerance can be controlled down to the nanometre range. The distribution of the NC (Noise Criterion) point is optimally adapted to the machining tolerance, resulting in a homogeneous milling pattern. The second of these is the ‘Smooth Overlap’ function, which improves the surface quality of transitional areas, making transitions so smooth that they are hard to measure and almost invisible to the naked eye.

The new five-axis radial machining makes hyperMILL even more important for industries that require high-quality moulds, such as the food and beverage, pharmaceutical, cosmetics, household goods and automotive industries.

The CAD/CAM suite covers every process from the data import to the NC code simulation — and that includes electrode manufacturing and wire EDM. hyperMILL offers extensive options to automate the CAM programming process and can be integrated into higher-level systems such as MES (manufacturing execution system) or PLM (product lifecycle management) systems.