Northants Precision Ltd

Northants Precision Ltd, a precision engineering CNC machine shop specialising in turned and milled components, has invested in a new, high-performance Lynx lathe supplied by

Mills CNC, the exclusive distributor of DN Solutions’ (formerly Doosan) and Zayer machine tools in the UK and Ireland.

The latest arrival, a 6in chuck Lynx 2100, was installed in the company’s 1,750ft

2 facility in Northampton in September 2022 to help meet a significant increase in demand for high-precision machined components from its growing motorsport customer base.

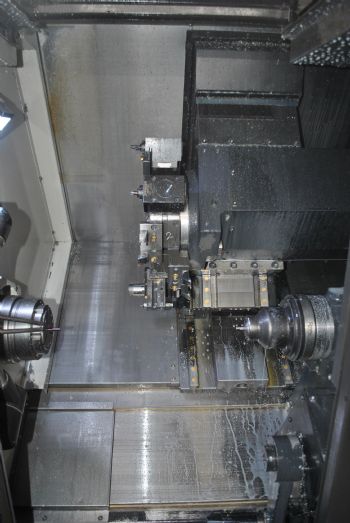

The new Lynx 2100 has taken its place alongside three existing Lynx lathes which comprise a Lynx 2100LMB and a Lynx 2100LB, purchased by the company in May and December 2021 respectively, and an older Lynx 220LSY lathe, equipped with sub-spindle, Y-axis and driven tooling capabilities, that owner and director, Daniel Green, already had in his possession when he established the company in August 2020.

Together, these four Fanuc-controlled lathes, two of which have integrated multi-tasking capabilities, provide Northants Precision with a formidable in-house machining resource, dedicated to the quick-turnround machining of small, complex and high-precision turned and milled parts.

Parts machined on the Lynx lathes are small, typically round and cylindrical in shape, and are held securely in position using 5C collet chucks to ensure high accuracy and the high precision machining of intricate features. They include components for F1, chassis for rally and super cars, sub-frames, gearboxes, track rod ends and engines.

High precisionPart volumes vary, from one-offs through to large batches, and everything in between, and are machined to high precision — typically +/-5µm on specific features — with super-fine surface finishes. A majority of components are made from difficult-to-machine materials that include heat-treated stainless steels – predominantly 13-8 PH and MP35N (a nickel-cobalt alloy).

Mr Green said: “Lynx lathes are real workhorses and are flexible and reliable. With their powerful, high-torque spindles, 12-station turrets and impressive rapid rates, they deliver the high part accuracies, repeatabilities and fast processing speeds required when working in the motorsport sector.

“Furthermore, Lynx lathes are competitively-priced, and we acquired our machines through Mills CNC’s Finance operation enabling us to take advantage of favourable credit and repayment terms. Since being installed, the new machine, like the other Doosans we have out our disposal, hasn’t missed a beat.”

Northants Precision is definitely a company whose growth, despite its relative infancy, is on a steep upward trajectory. It is a remarkable success story that belies its humble beginnings.

Back in August 2020, during the height of the pandemic, Northants Precision was established and operated out of shared, rented premises with only the Lynx 220LSY lathe, a shadow graph, a couple of micrometers and not much more.

The company had, effectively, one customer on its books and the focus then was on machining a range of high-precision motorsport components as well as specific parts, which the customer required for the Government’s ‘Ventilator Challenge’.

Post-pandemic business opportunitiesMr Green recalled: “It was tough at the beginning, but I was committed to growing the company. With my knowledge and experience of the motorsport sector and its supply chain imperatives, I was convinced that, by investing further in advanced machining technologies and by developing our in-house manufacturing processes and systems, we would be able to capitalise on post-pandemic business opportunities in a structured and systematic way.”

Surviving and growing in the motorsport sector isn’t easy, especially for a new start-up sub-contract company. There are many problems, potential pitfalls and banana skins that need to be avoided and negotiated to ensure success.

Mr Green continued: “Motorsport is a demanding sector. In addition to supplying ‘right first time — every time’ high-quality, competitively-priced machined components, and meeting ever-stringent delivery deadlines, it is important to have highly efficient, effective and reliable software systems in place that help streamline the entire production process, from quotation to invoice, and that make it easy to record and retrieve pertinent business information.”

To facilitate this, Northants Precision invested in Bracknell-based

PSL Datatrack’s production control system early on – a strategic decision, as it turned out, that proved instrumental in helping the company achieve ISO 9001 accreditation in double-quick time (see

Machinery Market’s article on the investment in PSL Datatrack at Northants Precision

here).

From its original shared rented premises, the company, after eight months of trading, moved to a larger 800ft

2sq facility in Northampton: but, with three machines being installed in the machine shop, this proved to be only a temporary solution.

Mr Green explained: “Although a significant step-up from where we were originally, we were still struggling for space in our second facility. With demand for our services growing fast and with the acquisition of a number of new customers, it became clear that we needed to invest in a fourth machine and that meant finding larger premises.”

New Lynx 2100The move to its current location was planned and timed to coincide with the arrival of the new Lynx 2100 in September 2022. The new premises, although providing the company with a much-needed increase in floorspace, did require a significant refurbishment. A new floor needed to be laid and painted, new power cabling needed to be installed and the whole facility needed to be revamped and modernised.

To achieve its production deadlines and minimise downtime, Northants Precision worked closely with Mills CNC to ensure that the new Lynx 2100 and the three other lathes located at its existing premises, were delivered and installed at the new facility.

Mr Green added: “Mills did a great job delivering and installing the machines. I think we only had a couple of days downtime before the entire move, from start to finish, was completed.”

Investing in new machine tools to cope with the increase in demand for its high-quality machining services has resulted in the company also increasing its headcount.

Mr Green said: “There was just too much to do for one person. So, in January 2022, I recruited an experienced machinist to help take the pressure off me, and to enable the machines to run longer.”

Northants Precision has come a long way in a relatively short period of time and its investment in DN Solutions’ machine tools has played, and continues to play, an important role in its growth and success.

But the story doesn’t end there. To meet the high-volume production requirements of a new motorsport customer, Northants Precision has taken the plunge and invested again. This time in a pre-owned sliding head lathe and bar feeder that will be delivered and installed at the company’s new facility in January 2023.