West Yorkshire-based

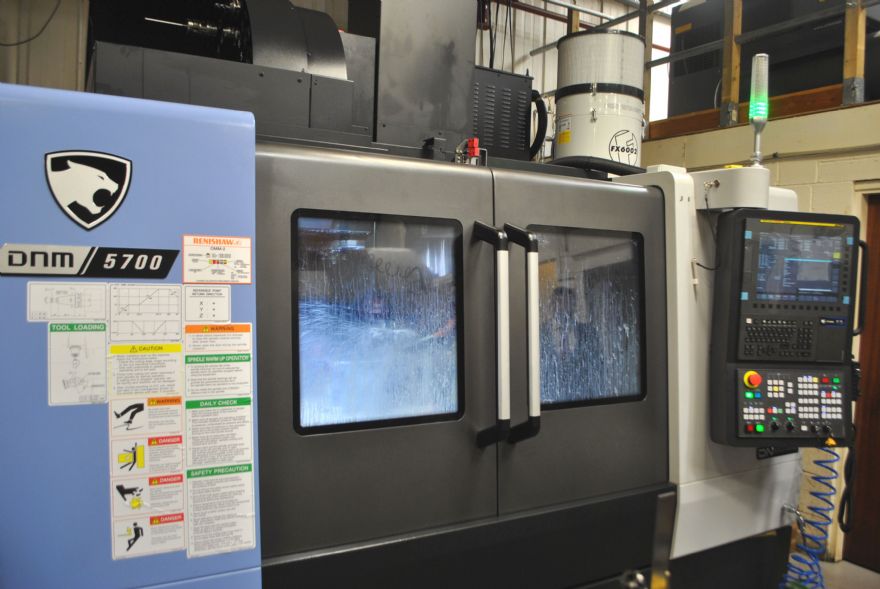

Helmrick Engineers Ltd, a leading precision sub-contract specialist, with a facility in Dewsbury, has been supplied with a new DN Solutions’ DNM 5700 three-axis vertical machining centre (VMC) supplied by Leamington Spa-based

Mills CNC, the exclusive distributor of DN Solutions’ (formerly Doosan) and Zayer machine tools in the UK and Ireland.

The machine, a popular and best-selling DN Solutions’ VMC equipped with the latest Fanuc 0iM control, a directly-driven Big Plus BT40 18.5kW 12,000rev/min spindle, a 30-position automatic tool changer (ATC) and a 1,300mm x 570mm worktable with a 1,000kg table load, has replaced two, older machining centres and was installed at the company’s 8,000ft

2 facility in March 2023.

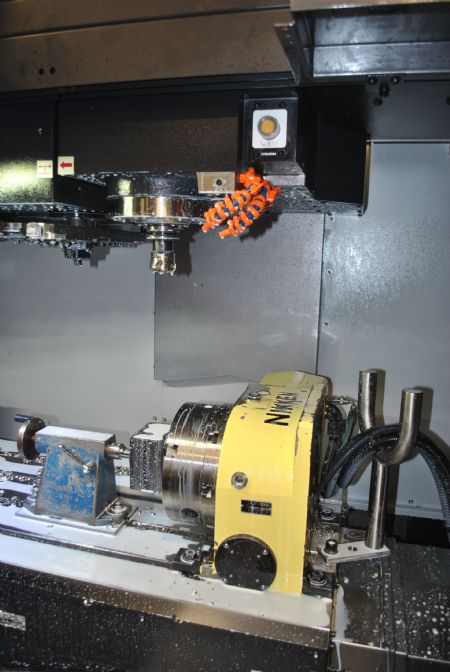

Since its arrival at the family-owned business, which shares its facility with sister company Anglo Stainless Ltd, the DNM 5700, which was supplied with a Nikken 4th-axis unit and a Renishaw tool setter and probing system, has been put through its paces machining a range of high-precision ball valves, needle valves and flange-type parts, as well as hydraulic and pneumatic fittings.

Mark Webster, Helmrick Engineer’s general manager, said: “The parts we supply are made from a range of tough and difficult-to-machine materials that include carbon steels, stainless, duplex and super duplex stainless steels and titanium, as well as, increasingly, from exotic alloys such as Inconel 718 and 925. They are machined from either solid bar or near net-shape and ‘upset’ forgings, for customers operating predominantly, but not exclusively, in the oil and gas and petrochemical industries.”

Parts machined on the new DNM 5700 are supplied in small batches, typically one- and two-offs through to 30-off, and are characterised by their high-precision of +/-30-50µm and exacting surface finishes down to Ra 0.6µm.

Increased machining capacity and capabilitiesThe decision to invest in the new DNM 5700 was made to help the company increase its machining capacity and capabilities. An in-house review, conducted in the autumn of last year, into the performance of its existing milling machine tools revealed that production throughput and manufacturing output was being compromised by two older machines the company had at its disposal.

Mr Webster said: “We identified a couple of productivity issues with two of our older machines. The first concerned their reliability which, in addition to potential spiralling repair and maintenance costs, could affect their uptime. The second involved the machines’ ability to consistently achieve the fast processing speeds we require while still meeting our customers’ tight tolerances and high surface-finish requirements.”

As a consequence, the company made the decision to trade-in these two machines for a new machining centre with a larger working envelope and more powerful spindle technology in order to strengthen its milling resource.

Helmrick Engineers is no stranger to Doosan machine tools from Mills CNC having previously invested in a number of them over the past few years — the most recent of these being the acquisition of a heavy-duty Mynx 6500/50 machining centre in 2018.

Mr Webster added: “We have a good relationship with Mills CNC and like its business approach, after-sales service and technical back-up. Having discussed our plans with Mills CNC and been presented with the technical specifications of the DNM 5700, we decided to place the order.

“We opted for a Fanuc-controlled model owing to its availability, its relatively competitive price (viz-a-viz the Heidenhain alternative), and our belief that Fanuc controls represent the ‘industry standard’.

Positive impactAlthough the new machine has only been up and running for a few weeks it is already having a positive impact on Helmrick Engineers’ performance. On one specific valve component, cycle times have been reduced by up to 20% with no compromise in part quality.

Mr Webster continued: “The DNM 5700 is a rigidly-built machine, and with its advanced spindle technology, we are able to ramp up speeds and feeds to improve part processing times. Having been relatively quiet on the investment front over the last few years, we are now embarking on a new chapter in the company’s history – one that will see more investment that will help facilitate diversification into new sectors.”

Helmrick Engineers was established in 1973 by the Brooke family and today employs 11 members of staff. Two years ago, current owner and managing director, Steve Brooke, took full control of the business and implemented a ‘root and branch’ continuous improvement programme designed to help the company grow, strengthen its position within existing customers’ supply chains, and diversify its operations to attract new customers from different industrial sectors.

The company-wide continuous improvement has, over recent months, resulted in Helmrick Engineers making significant investment in its people, in its plant and equipment and in its systems and processes. Furthermore, the company has recently achieved ISO:14001 certification to add to its ISO:9001 accreditation and expects to achieve ISO 45001 certification in the next few months. Helmick Engineers has also introduced a strategic recruitment programme designed to increase its headcount and attract ‘younger talent’ into its ranks to alter the age profile of the company and address any potential future skills shortage problems.

The company has recently acquired additional premises, adjacent to its existing site, providing it with an extra 7,000ft

2 of floorspace which will be used to relocate its Anglo Stainless operation and free-up space for Helmrick Engineers’ machine shop, offices and administration.

Helmrick Engineers, armed with a new vision and a commitment to growth, is now actively exploring new business opportunities in the rail, nuclear and renewables’ sectors while still continuing to work with its existing customer base. It is anticipated that the company will continue to invest in high-performance machine tools and associated technologies and is investigating the potential of multi-axis and multi-tasking machines as well as automation to help it further improve its productivity and process efficiencies.

Mr Brooke concluded: “It is an exciting time for the company and we are determined to realise our full potential.”