German high-tech companies

Trumpf and bicycle brake manufacturer

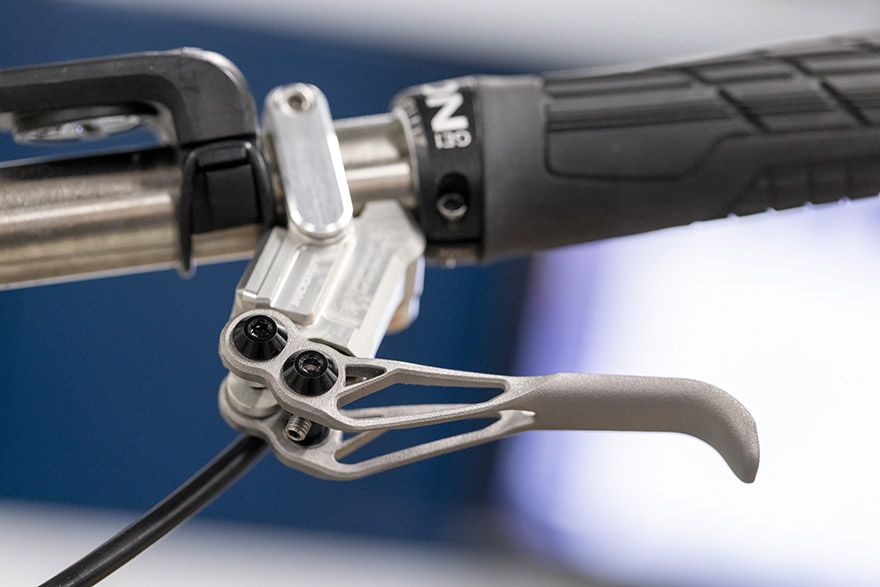

Trickstuff presented titanium brake levers for bicycles made by 3-D printers for the first time at the recent

Eurobike Bicycle 2023 trade show in Frankfurt.

Until now, the bicycle industry has often used carbon as a material for high-quality brake levers, but this material has a poor environmental record as the material cannot be recycled. Manufacturers must dispose of these parts after their life cycle, usually in waste incineration plants. Titanium has a better environmental footprint compared to carbon and is also far more robust; manufacturers can make much stronger brake levers and employ 3-D printers to customise them.

This applies not only to the design of the titanium components — manufacturers can also customise the lever forces of the brake to suit the cyclist. Christian Lengwenat, application engineer at Trumpf, said: “Since our 3-D printers are also designed for series production, the bicycle industry can use them to manufacture large quantities of parts. As a result, components that are subject to heavy stress can be produced cost-effectively.”

Mr Lengwenat concluded: “Using 3-D printers, manufacturers can produce different prototypes simultaneously in one process. This speeds up the prototyping process, which is important for the bicycle industry, many times over.” Until now, manufacturers have mostly milled the prototype parts which is time-consuming and expensive.