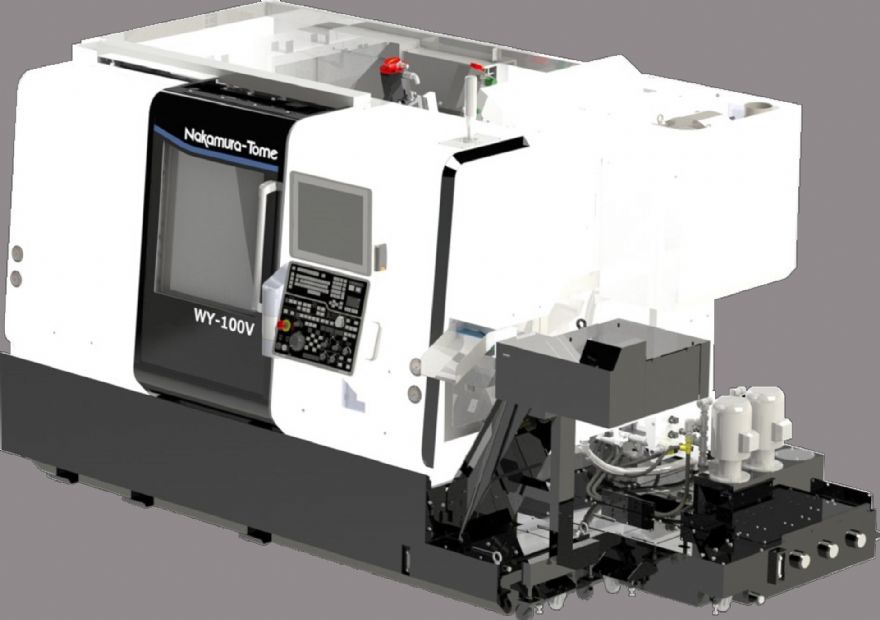

Nakamura-Tome will be giving a world exhibition premiere to its latest WY-100V twin-turret twin-spindle precision CNC multi-tasking turning centre at

EMO Hannover 2023 (Hall 17, Stand B34), taking place 18-23 September. The new machine represents a completely new multi-tasking lathe that is the manufacturer’s fastest yet and comes with productivity enhancing features. Soon to be available in the UK from the Engineering Technology Group (ETG), the new machine will be presented at

EMO under the banner ‘Faster than the fastest’.

For those familiar with the Nakamura brand in the UK, with machines supplied by the Wellesbourne-based

Engineering Technology Group (ETG), the WY-100V promises to be a groundbreaking machine with a host of new technologies that will significantly reduce cycle times. Seven years after the launch of its predecessor, the groundbreaking WY-100II machine, the new WY-100V has been developed to take multi-tasking productivity to an even higher level.

The WY-100V features a newly developed software technology called ‘ChronoCut’ which minimises idle time during manufacturing without compromising accuracy, even without any changes to the cutting conditions. As a result, Nakamura has significantly reduced cycle times by up to 30% in some cases.

Further improvements in precision Furthermore, new hardware and software solutions have been developed to improve the accuracy that bears faster mass production. The new machine will also demonstrate the enhanced NT Thermo Navigator system. This thermal growth compensation software uses temperature information of the entire machine to perform efficient corrections. This enables further improvements in precision that are complemented by a newly designed machine structure that minimise the influence of thermal growth. The new WY-100V 6in chucking lathe will be available with a 42, 51 and 65mm diameter bar capacity with a maximum turning length of 588mm.

Nakamura-Tome CEO Shogo Nakamura said: “In a multi-turret machine, speed is of utmost importance. By reducing cycle time with a fast machine, you can make a large number of workpieces within the same amount of time and effort. This helps customers to save manufacturing costs in challenging cost-cutting situations and it alleviates concerns about tight delivery deadlines.”

“The WY-100V is a machine that embodies the concept of ‘Faster than the fastest.’ It aims to reduce the burden on the shop floor where even a few seconds of cycle time reduction can bring great benefits. We have set a high goal of aiming for a 30% reduction in cycle times and this has been demonstrated through developing the new machine from scratch. It is a machine that incorporates all of our hardware, software, and machining expertise.”

Experts from ETG will be at

EMO to present this exciting innovation to UK manufacturers while Nakamura will be providing several technical presentations each day. Mr Nakamura will be at the event to meet potential customers and stand visitors.