Seven of

Advanced Grinding Solutions’ principals will be exhibiting at

EMO Hannover 2023, taking place 18-23 September — Rollomatic, Tschudin, Gerber, Meccanica Nova, Comat, FLP Microfinishing and GPA Innova — and AGS representatives will be present throughout the event on the stands.

Taking centre stage on the

Rollomatic stand (Hall 6, Stand E66) will be the company’s Smart Factory; a proven concept designed to meet the new challenges faced by cutting tool manufacturers. It provides a new way to organise production resources using information technology, machine communication systems and robotics. Meanwhile, the new Lasersmart 810XL, designed for machining large-diameter tools, will also be highlighted.

Designed for the production of cutting tools in ultra-hard materials and featuring six simultaneously interpolated axes, the new, ultra-compact Lasersmart 810XL has been designed to machine tools up to 300mm in diameter, 350mm in length and weighing up to 15kg. An automatic loader with a capacity of 30 parts is also included as standard. Also on display will be high-performance ‘lean’ grinding solutions from the Smart Autonomous Grinding programme and the latest Strausak One five-axis grinding machine which is designed for the production of special tools, inserts or resharpening. Strausak, which celebrates its 100th anniversary this year, joined the Rollamatic Group in 2011.

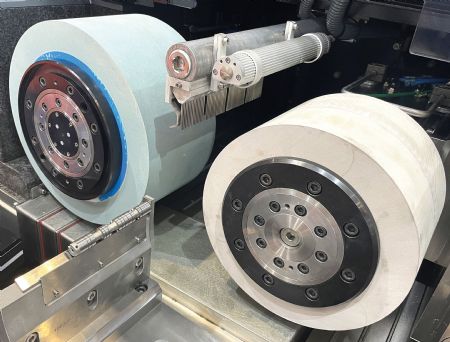

Award-winning Cube 350Tschudin (Hall 11, Stand E31) will put the spotlight on the award-winning Cube 350 with a robot loader and the ecoLine 400 will also displayed. Tschudin’s CEO Iwan von Rotz said: “Our customers grind workpieces of the most diverse sizes on our machines, from the smallest wires for medical technology to tapered roller bearings weighing up to 11kg for use in large-diameter bearings for wind turbines.”

The Cube 350 is designed for machining small workpieces up to 20mm in diameter, the 400 ecoLine/proLine is suitable for machining medium-sized workpieces up to 150mm in diameter, and the 600 ecoLine/proLine can machine workpieces up to 250mm in diameter. The maximum grinding wheel width is 500mm.

The Cube uses Tschudin’s patented W axis which has the workrest blade mounted onto its own CNC axis that allows for parts to be loaded to it outside of the grinding area making loading efficient, fast, and very safe. Traditional centreless grinding machines require parts to be loaded to a fixed work-rest blade that sits inside of the machine between the grinding wheel and control wheel making loading difficult, more expensive, and sometimes unsafe. This also makes changeovers more complex and therefore lengthier.

The Tschudin machine overcomes all of these issues and claims to be the world’s easiest and fastest centreless grinding machine to set up. Tschudin centreless cylindrical grinding machines are used in all industrial sectors where mechanical components are required with high accuracy and at economical unit costs – from medical technology and the bearing industry to hydraulics, automotive engineering, drive technology, toolmaking, and aerospace. The materials machined, such as steel, aluminum, glass, titanium, carbon, ceramics, or silicon, are just as versatile as the areas of application.

Unparalleled flexibilityGerber (Hall 11 stand D51) will be launching its latest deburring machine at

EMO — the BP Motion. This machine is designed for deburring, edge honing, and polishing and offers ‘unparalleled flexibility, dynamic performance, and digital capabilities’. It has been designed to remove sharp edges and burrs, brush defined radii and contours on edges, and to polish surfaces to the highest levels.

With its extended speed range of up to 1,000rev/min, the BP Motion delivers deburring results at speed and features precise automatic brush measurement and automatic compensation for brush wear to ensure maximum process reliability. For producing small, medium, or large batches of parts the BP Motion is the perfect choice. With a variety of applications for flat and slightly curved parts, this machine offers incredible versatility. Thanks to its Industry 4.0 connectivity and preparation for fully integrated automation, it also provides the highest level of productivity.

One main application for the Gerber machines is the edge preparation, deburring and polishing of all types of cutting tool inserts and Gerber are able to list worldwide industry leading clients such as Plansee-Tizit, Sandvik, P Horn, Sumitomo, Iscar, and Kennametal among its many end users. Apart from insert production, Gerber machines are also used in the medical industry and for the manufacture of valve plates, pump components and rotors etc, whereby parts need to be de-burred with edge forms being controlled.

Meccanica Nova (Hall 11, Stand D07) manufactures flexible CNC grinding machines that feature excellent accessibility for quick change-over, serviceability and maximum up-time while providing the rigidity required for the most demanding of grinding applications. The range comprises of internal, external, combined and special grinding machines for the bearing and constant velocity joint industries.

Meccanica Nova internal grinders are used to make small parts, such as bearings, valve lifters, and huge parts such as landing gear struts. Three work holding systems are available; roller/shoe type, magnetic/shoe type and chucking with front loader or through the spindle. Tooling costs are low and change-over is rapid. The bearing industry typically uses the magnetic/shoe system. Parts must be made from magnetic steel and have a ground OD and face. When the part has a ground OD the roller/shoe system is used.

Chucking systems are available when the parts do not have ground external surfaces. External grinding is critical to many manufacturing organisations. The performance of parts such as bearings and CV joints are directly tied to how well they are ground. At the same time external grinding is a bottleneck for most manufactures.The Nova PGE series of external grinders are built to achieve roundness of less than 0.0005mm with cycle times as short as a few seconds. Dressing systems are available to shape the wheel for roller bearing tracks, ball bearing grooves and C-V Joint cage OD’s.

Maximum coolant consistencyComat (Hall 6, Stand F42) will be displaying super-filtration systems that deliver ≤2-3μm filtration quality (making oil cleaner than unused oil as supplied new) and importantly do so throughout the entire working cycle while minimising lifetime running costs and maintaining maximum coolant consistency. Importantly for end users, the Comat filter systems use their Intelligent Performance Technology that allows them to be remotely monitored in real-time during the manufacturing processes with customers filter systems fine-tuned by Comat to ensure that the optimum filtration quality is obtained at all times.

Furthermore depending upon the model the Comat filter units can be monitored, controlled, and optimised by integrated controls or externally by PCs, tablets or smart phones. Today, more than 20,000 machine tools use Comat Filtration Systems, with more than 120,000,000 litres of metal working oil being super-filtered every single day. Comat operate globally and have a 30-year history in developing the most advanced filtration systems that are available.

Comat's Superfiltration Technology uses continuously regenerating filtering media (diatomaceous earth, cellulose or other vegetable media), to ensure that particles larger than ≤2-3μm are removed from cutting fluids and the fluid is maintained at a stable desired fixed temperature of +/-0.2 deg. Main applications for these filter systems include tool grinding on Rollomatic and similar grinding machines and also on turning machines and automatic lathes. Comat systems can operate with any oil having a viscosity ranging between 5 and 30 Cst at 40°C.

The filtration levels from the Comat systems are so high that new virgin oil has to be go through several regeneration cycles in order for it to meet the finer filtered quality of older/used oil that is filtered with Comat filter systems. The low-cost media used in Comat systems is very cost-effective and as there are no cartridges, paper rolls or expensive candles to replace; Comat filters offer the lowest running costs of filter units.

Latest generation FLP machinesMeanwhile, the latest generation of

FLP Microfinishing machines will be highlighted at

EMO (Hall 11, Stand C46). FLP is the only company in Germany to offer the entire range of industrial fine grinding, lapping and polishing machines for flat surface finishing from a single source. The four FLP product areas are new single- and double-sided machines (both standard and full CNC), fully rebuilt and refurbished machines, the supply of lapping consumables and tooling, and a large sub-contract lapping facility.

The broad range of FLP fine grinding and lapping machines includes for both twin wheel – double-sided CNC lapping machines as well as single-wheel machines. Around 25% of FLP sales are for fine grinding machines that offer two-three times the stock removal of more traditional lapping machines with 75% of sales being for Lapping machines that are used where there is a low stock removal requirement with a mirror finish and perfect flatness.

The fine grinding process, that uses diamond or CBN wheels, is much cleaner than lapping and virtually eliminates work piece cleanliness issues. Furthermore, this process is many times faster than lapping and bridges the gap between traditional lapping and standard grinding technologies. Fine grinding creates a micro cross-hatched finish on parts that is akin to one after a Superfinishing operation that has advantages in terms of surface retention of lubricant while still offering very high degrees of flatness and a mirror like surface.

The revolutionary DLyte polishing machines produced by

GPA Innova (Hall 11, Stand C13) benefit from using the world’s first dry electro polishing process. The DLyte range of machines use a totally unique, single-step automated process, for polishing metals; this is a revolutionary dry non-abrasive electro polishing process that does not use any liquid as the electrolyte.

These new patented machines polish and deburr steel and stainless-steel, cobalt chrome, titanium, aluminium, nickel and precious metal alloys components for a range of industrial sectors including dental, medical, aerospace and automotive. Typical applications include bone screws, artificial hip and knee joints, turbine blades, cutting tools, and any similar component whereby fine surfaces finishes to under 0.09um Ra are required without altering key part geometry after the previous grinding or milling process.