North Essex-based

www.ritchie-engineering.co.uk Ritchie Engineering Solutions Ltd is a family business which prides itself on bespoke engineering product design and manufacturing quality items. Run by brothers Duncan and Alasdair Ritchie, the company has a strong ethos for precision engineering which feeds into everything it designs and produces.

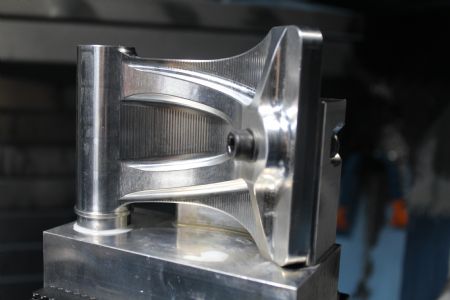

A ‘concept-to-cart’ company which now produces components for customers in the motorsport, automotive and aerospace sectors, Ritchie Engineering Solutions was founded back in the 1980s, when Duncan and Alasdair’s father left his full-time job to follow his passion — manufacturing steam launch engines.

From his shed in the back garden, he worked alongside employee John Riffel, to build up the business. During this time of manufacturing steam engines and steam plant, Ritchie’s thermodynamic and mechanical engineering expertise led him to be invited to work on Richard Branson’s trans-atlantic hot air balloon record attempt in the mid-1980s. He was tasked to produce the high-altitude propane burners and capsule pressurisation equipment, which would be instrumental in the balloon successfully flying from the USA to the UK — a world first.

After the passing of their father, Duncan and Alasdair decided to carry on the legacy of Ritchie Engineering Solutions. Still running from the shed in his mother’s garden, Duncan managed to squeeze in a CNC Lathe and four-axis CNC mill. Alasdair, who had in the meantime completed a degree in engineering design, left his full-time job to team up with Duncan and over the last eight years Ritchie Engineering Solutions has gone from strength to strength. The brothers now have a facility in Manningtree, employ nine people and to-date have ploughed back more than £1.2 million into the company. Ritchie Engineering Solutions relies on the expertise of Ceratizit UK & Ireland Ltd for guidance with machine inserts and tooling. Adam Cross, Ceratizit’s technical sales engineer, first started visiting Ritchie Engineering Solutions in 2015 and has been a constant source of technical support to the two brothers ever since.

Expertise of CeratizitDuncan said: “Working with Adam has been invaluable and has been integral to our journey. He never just sells us tools — he solves problems for us and helps us to improve our processes. Working with him has given us the confidence to quote on jobs and be more competitive in the engineering industry. He is always at the end of the telephone, and we have never had any problem contacting him when needed. We really can’t sing his praises more highly or thank him enough for the help he has provided.”

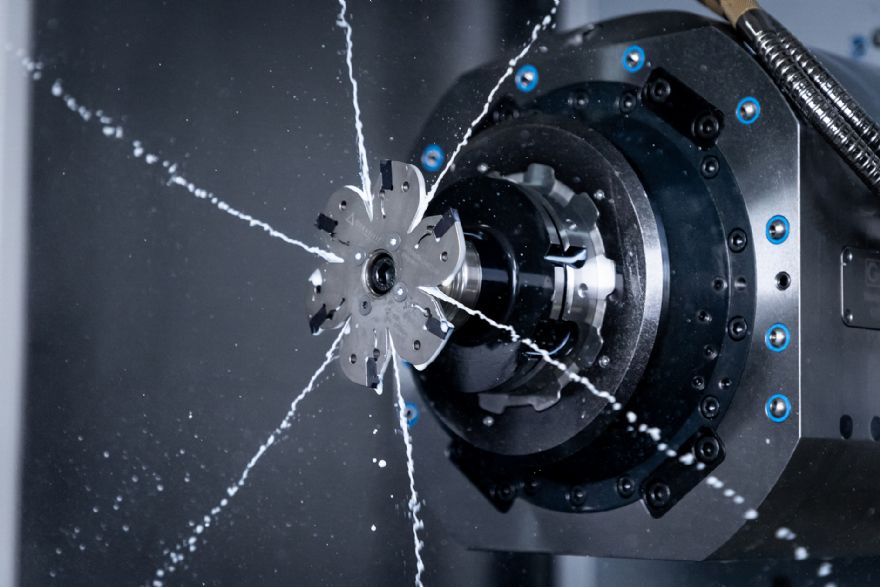

In addition to Adam’s support, the tooling provided by Ceratizit has had a huge impact on the costs and operations within the workshop. On the company’s Matsuura machine, which is running 24/7, Ceratizit’s inserts have more than doubled the tool life when compared to the ones which were previously used, and this has equated to a considerable saving in overall tooling costs. The MaxiMill SX indexable parting-off tool in particular has been a stand-out product for the company, as its reliability has meant that Ritchie Engineering Solutions has been able to run more single-operation jobs and conduct more lights-out running. This has allowed products to be manufactured much quicker and with considerably less scrap from damaged parts.

Alasdair said: “Investing in Ceratizit’s tooling has always been worth it for us, as investment in quality tooling means a longer tool lifetime and more reliability, which in the long run saves a lot of money. Ceratizit has a holistic view to tooling — it is never just about the company just making a profit, everything that is recommended to us is done with consideration for our processes and their profitability.”

Like many companies who work in partnership with Ceratizit, Ritchie Engineering Solutions also has a Ceratizit vending machine in the workshop so that inserts and tools can be accessed immediately. Duncan continued: “There are two practical elements to having the vending machine here. Firstly, it means that there is a robust supply chain, and secondly that we have spares available when we need them. Ceratizit tooling is now an integral part of our every day machining, so having tools on demand is great news for us.”

Ritchie Engineering Solutions, with Adam’s support over the years, has grown into a business which is able to retain competitiveness while not compromising on the quality of what it produces. This ethos for quality, which has been passed down from their father, lies at the heart of the company. True to the heritage of where the business began, it still produces parts for hot air balloons, although these have advanced since their original designs from the 1980s.

Duncan concluded: “We are excited to experience what is to come for Ritchie Engineering Solutions and the ever-evolving tool range from Ceratizit means that we can improve our processes as and when appropriate tools and associated cutting strategies are recommended to us.”