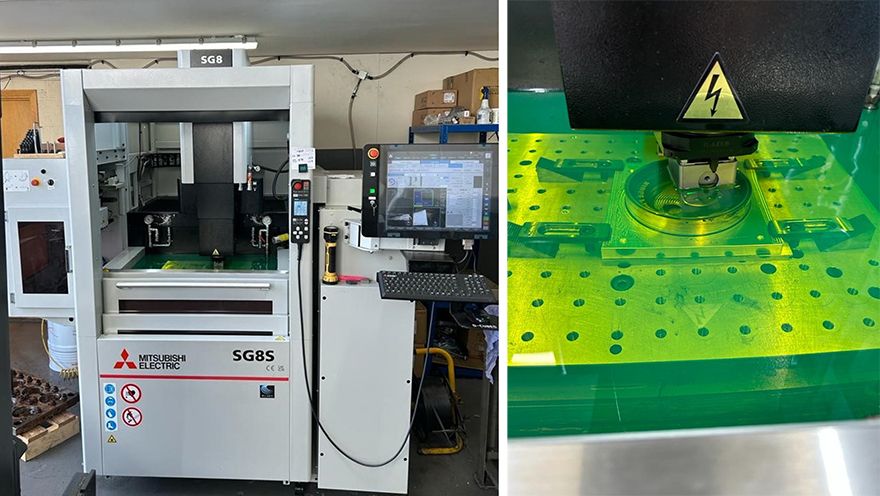

The Mitsubishi SG8 die sink EDM from ETG at MJ Toolmakers

The Mitsubishi SG8 die sink EDM from ETG at MJ ToolmakersAs a specialist toolmaking business that works with customers from concept through to manufacture, Market Harborough-based

MJ Toolmakers Ltd has gone from strength to strength since its establishment in 1995. Producing everything from mould tools, injection mould tooling, aluminium and zinc cast tooling, and extrusion die tooling, the company is witnessing an ongoing period of sustained growth. It is the continuous upturn in business that has seen the company acquire two Mitsubishi EDM machines from the Wellesbourne-based

Engineering Technology Group (ETG).

As an established manufacturer with a range of manual and CNC machine tools on the shopfloor, MJ Toolmakers was witnessing capacity issues in its EDM department which consisted of four machines. In addition,the company has a stringent policy to replace machine tools after five years of operation - this means that the 11-employee business is always running the most up-to-date technology available.

MJ Toolmakers’ director Paul McDermott said: “We needed to replace an ageing machine and we were intent on investing in a ‘greener’, more cost-effective and more powerful machine. Simultaneously, we know that a new machine would improve productivity while reducing our costs.”

With a mixture of wire and spark erosion technology, the company undertook a full review of the marketplace and it took delivery of a Mitsubishi MV1200S wire erosion machine in January 2023 which was rapidly followed by a Mitsubishi SG8S die-sinking machine in March 2023. With no prior experience with Mitsubishi machine tools or working with ETG, Paul’s brother and fellow director Nathan, added: “We reviewed the entire marketplace and ETG offered us the best machine with the best performance at a cost-to-performance ratio that met our needs. Additionally, the large work area of the Mitsubishi MV1200S with an extremely small footprint was a very attractive proposition for our workshop.”

Prestigious reputationSince the machine was installed in January, it has been running 24/7. Nathan added: “Our business works across a range of industry sectors from the nuclear, marine and oil and gas markets to the point of sale, automotive and electronics. With a prestigious reputation as industry-leading toolmakers in all of these markets, we have been able to reshore work from Europe and the Far East. Sadly, a lot of toolmaking businesses went under during the Covid-19 pandemic , but this has resulted in a lot of extra available work for toolmaking specialists like ourselves.”

Nathan continued: “The MV1200S (pictured left) is running at least 85% of the time. As a business, we run 24/7 with lights-out machining and the Mitsubishi MV1200S has been running non-stop since we bought it — furthermore, it is running approximately six-times faster than our previous EDM machine.”

In comparison to the previous machine, the Mitsubishi MV1200S provides several benefits. Inevitably the ageing machine that was replaced incurred service issues while the power and consumable costs were higher than on the Mitsubishi MV1200S. This is because the Mitsubishi MV1200S incorporates next-generation drive systems and an optimum machine structure with linear shaft motors that help to improve surface finishes, and productivity rates and also prolong wire life. From an operational perspective, the Mitsubishi MV1200S has an impressive user interface that guarantees ease of operation and reduces the chance of human error for customers. With the information displayed on a large 19in screen, the innovative CNC system can also reduce set-up times by up to 40%.

Paul explained: “We can programme the Mitsubishi MV1200S online and offline and it is a very easy machine to use. From a productivity perspective, the machine is significantly faster than its predecessor, and being more than six times faster than the previous machine, it is difficult to quantify the savings in consumer consumption such as wire.”

Automatic spark systemThe instant impact of the Mitsubishi MV1200S led the company to add a new die-sinking machine to its inventory with the purchase of a Mitsubishi SG8S die-sinking machine in March this year. Adding this machine to the plant list, Paul said: “We needed more capacity, and the compact machine has an extremely small footprint with an automatic spark system and a 10-position electrode changer to extend our unmanned running periods.

“We have one die-sink machine that has no tool change facility and another with four positions, so the 10-position electrode facility enables us to run for longer periods with significantly higher productivity rates. This not only reduces our set-up times and reduces manual intervention, but the machine also achieves significantly reduced electrode wear.”

This is a credit to the new GV generator that has been designed for a wide range of applications. Excellent performance with extremely low electrode wear can be achieved when using graphite electrodes and the creation of intricate details and high surface qualities is possible with copper. The generator is just as suitable for machining carbide as for machining titanium and many other materials.

Paul concluded: “We have been very pleased with the service from ETG and the quality of the Mitsubishi machines is second to none. We are extremely happy with the machines and they have been working 24/7 since their arrival.”