A powered broaching unit located in a ‘live tool station’ and using a broaching system of holders and inserts from Horn Cutting Tools Ltd, Ringwood

(www.phorn.co.uk), has allowed Banbury-based composite-systems specialist CTG Ltd to reduce the time needed to produce a series of splines on the inner circumference of stainless-steel trunnion-style shaft connectors/end fittings from 6min to 1min.

The broaching equipment, which is driven by the live tooling facility on the turret of a CNC lathe, was supplied and installed by Horn Cutting Tools. It is allowing CTG to meet increasing demand for 85 variants of the components, which are an interference fit on the ends of filament-wound carbon-fibre hollow shafts used in a multitude of aerospace and automotive applications.

CTG production manager Martin Pacey says: “The splines are produced to very tight tolerance, because we require an extremely secure fit without the use of adhesives. We actually defined the basic spline pattern some years ago, but we were reliant on using pull-broaching to produce it. This had various disadvantages: the tooling was fier-cely expensive, and each diameter needed a dedicated tool — plus we were reliant on a supplier whose future was uncertain. Moreover, pull-broaching was not able to satisfy an emerging requirement for broaching splines in a blind hole.”

Horn’s initial contact with CTG came about due to the blind-hole requirement, and a successful solution was duly delivered. Like most applications of broaching on a lathe to date, it relied on movement of the entire Z-axis saddle and turret assembly to move the tool back and forth, while rotary indexing of the component was taken care of by the lathe’s C axis. Although this process was successful in terms of fulfilling the machining requirement, the large masses being moved around meant that it was much slower than pull-broaching, taking around 6min per component compared to 1min for the pull-broaching operation. However, the flexibility provided by the Horn system offset any disadvantage of the additional time — plus components came off the machine complete, with the orientation of the spline being accurate relative to a datum.

“We could tolerate the longer cycle for the small number of blind-hole connections then required, but rising demand for products using the connectors dictated the need for a much faster method of machining through-hole splines,” said Mr Pacey. “Pull-broaching was not a viable long-term solution, and methods other than broaching were considered. However, when Horn discussed a turret-mounted broaching attachment, it was an obviously ‘right’ solution — provided that it could be made to work reliably.”

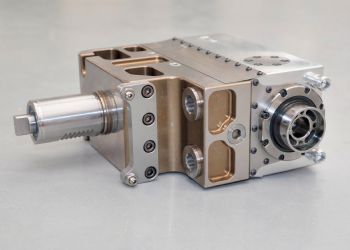

The attachment comprises a mechanism that is driven by the live tool facility on a lathe turret. This mechanism, which is enclosed in an oil bath, converts the rotary drive into reciprocal motion that propels the broaching tool backwards and forwards. Each mechanism is custom-built to provide a particular stroke length; to date, CTG has used variants with 20mm and 30mm stroke lengths. Generating the splines relies on tiny incremental movement of the X axis and periodic indexing of the C axis. The broaching tool itself is based on the Horn Type 117 insert with a precision-ground spline form housed in Horn tool-holders.

“During commissioning trials, the unit demonstrated the ability to maintain the same level of accuracy as a pull-broaching tool — and to match its speed. Moreover, whereas the pull-broach required a dedicated set of quite costly tooling for each size of connector, the Horn system can accommodate most sizes with just three insert variants. In addition, the actual cost of the broaching unit and tooling is very competitive, especially if you factor in the improved flexibility, relatively easy set-up and reduced wear and tear on the Z axis of the lathe. It is proving to be a very satisfactory solution.”