Rotherham-based

Productive Machines, a

University of Sheffield Advanced Manufacturing Research Centre (AMRC) spin-out, has unveiled the ‘Essential Optimization’ app; a powerful web application that prevents chatter vibrations and provides engineers with a simple-to-use solution to select optimum, stable spindle speeds and feedrates.

Powered by Productive Machines’ innovative machining dynamics algorithms, the new app promises to turbo-charge machining operations by mitigating chatter vibrations and cutting forces-related problems. This new capability enables manufacturers to increase productivity, reduce waste, improve surface finish and provides a brand new approach to stable milling by taking into account both the machine tool dynamics and the cutting forces involved prior to manufacture. This user-friendly Software-as-a-Service (SaaS), is designed to assist manufacturers in making their processes hyper efficient without the need for installed software or machining physics expertise.

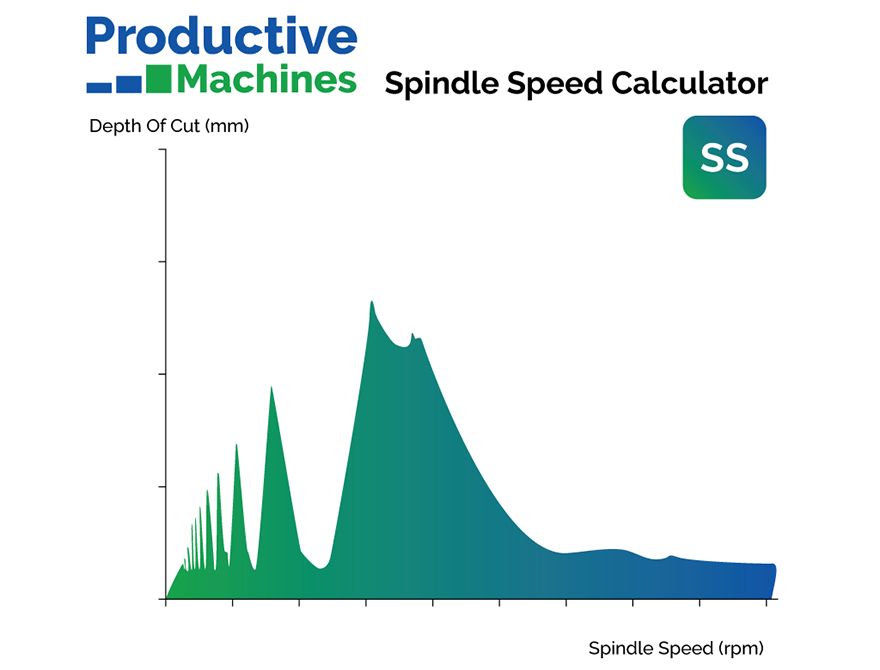

At its core, the Productive Machines’ Spindle Speed Calculator, part of the Essential Optimization app, relies on Frequency Response Function (FRF) obtained through tap testing. Tap testing is a technique used to identify the structural dynamics of the machine tool assembly. The Spindle Speed Calculator uses FRF data to generate a stability lobe, a visual representation to determine the stable regions. This invaluable tool guides engineers in making informed decisions, ensuring a chatter-free milling process.

The Essential Optimization app enables users to: increase productivity — by reducing cycle times and lead times to achieve more cost-effective machining operations; embrace sustainable manufacturing — by eliminating iterations and expensive prove-outs on machine tools that waste time, energy and materials; minimise tooling costs — by mitigating chatter vibrations to minimise tool wear and save on tooling costs; and provides quality assurance — by producing parts with optimal surface finish and dimensional accuracy.

Seamless integrationFurthermore, with the integration with ‘Feed Rate Calculator’ users can effortlessly input chatter-free spindle speed and depth of cut values obtained from the Spindle Speed Calculator into the Feed Rate Calculator. This seamless integration optimises feedrates by considering cutting forces, resulting in superior machining performance.

Productive Machines CEO Dr Erdem Ozturk said: “We are committed to providing cutting-edge solutions that assist engineers in reaching the best part, faster, and first time. Our Essential Optimization app represents a significant step forward in the quest for chatter-free machining. We are replacing trial-and-error processes with data. By combining tap testing data and innovative algorithms, we are providing a vital easy to use tool for the machining industry. This capability will be a direct input to our ‘digital twin’, enabling five-axis toolpath simulation and optimisation in 2024.”

Richard Nevill, commercial director at Productive Machines, said: “We are running TapStarter, a special promotion to get engineers/operators tap testing. Tap testing, enhanced by Productive Machines’ easy-to-use technology, brings precision and efficiency to manufacturing enabling operators to optimise machine tool performance, reduce waste, and enhance product quality.”

For more information about Productive Machines and to register for the free trial, please visit

here.