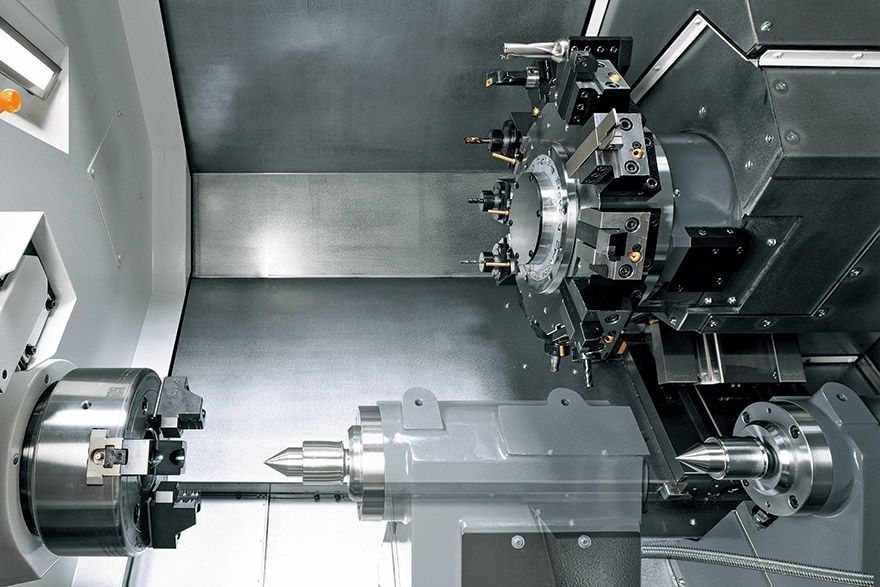

ETG Nakamura SC200IIL

ETG Nakamura SC200IILFollowing ‘hot on the heels’ of the new Nakamura-Tome SC-200II machine that recently launched as an evolution beyond its predecessor, the SC-200, Nakamura has now introduced the new SC-200IIL. As the UK and Ireland technology partner for the world-leading Nakamura-Tome brand, this latest iteration is now available from the Wellesbourne-based

Engineering Technology Group (ETG).

The new SC-200IIL turning centre inherits many of the main specifications of the recently launched SC-200II and its concept of ‘next level machining’. However, the SC-200IIL extends the distance between centres — evolving into a machine capable of machining long workpieces. This development allows users to select the R-side specifications from the sub-spindle or NT tailstock units. The SC200II has a maximum turning dia of 390mm and a 510mm distance between spindles; the new SC-200IIL increases this distance to 715mm between centres with 800mm between spindles.

Like the extremely rigid SC-200II multitasking lathe, the SC-200IIL provides a powerful and stable machining platform under the most challenging of conditions. Despite the machine being in the 8in chuck size class, it has a swing over the bed of 620mm dia, providing an exceptionally large machining area for a small footprint machine.

This also enables the machine to accommodate a 10in chuck if required. The output of the spindle motor has been increased to 15/11kW with the option of an 18.5/15kW motor. The exceptional spindle motor output, bar capacity and Y-axis travel have all been enhanced to give the new SC-200IIL machine the ability to accommodate a higher machining capacity.

Like the SC-200II, the SC-200IIL has impressive acceleration rates that enable the operator to machine larger parts and expand the scope and variety of components considerably. Moreover, the machine has a new frame structure that improves rigidity, performance, surface finishes and precision.

Nakamura CEO Shogo Nakamura said: “The SC-200II is our new multi-tasking machine with the concept of ‘Next level machining’. Since it is capable of processing large billets and bars that should be normally performed on a machine in a one-rank larger size, the SC-200IIL has now arrived to deliver favourable changes to factory floors. Another appeal of this machine is that the sub-spindle ‘MATA-BEI’ can be selectable on the R-side spindle. This allows end-face machining and enables operators to realise consecutive machining tasks from a blank material to finished parts in a single machine.”