BalTec

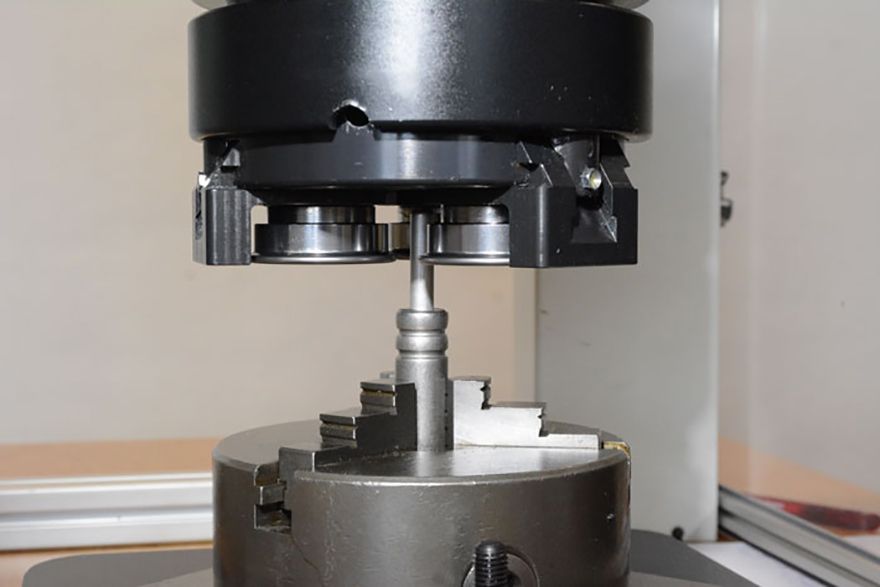

BalTec, the Swiss manufacturer of high-quality riveting and roller forming machines, which has a UK subsidiary — Baltec UK Ltd — in Reading, has introduced the new Electric EA30, which it says is ‘the world’s first roller forming machine with servo-controlled articulation’. With three individually programmable servos, the Electric EA30 can execute a variety of profile shapes in a single stroke, offering forming capabilities that include traditional roller forming, articulating roller forming, 3-D articulating roller forming, and crimping.

“What differentiates the Electric EA30 is the servo-controlled radial motion, which delivers significantly higher precision and control compared to conventional solutions that require manual adjustment of a mechanical stop. Another notable feature is the machine’s slim design, as all three servo motors are aligned within the unit, allowing for ready integration into automated production lines with limited space. It can also be used as part of a stand-alone work cell for prototyping or low-volume production where frequent changeover of nests and programs may be necessary.”

Meanwhile, the HPPi software of the Electric series not only allows programming and quick adjustment of the forming process using the HMI but also monitors all aspects of the forming process and stores the relevant process data. Furthermore, exporting this data through an industrial data interface (OPC/UA) enables integration into higher-level production management systems.

BalTec added: “The primary advantages of this innovative technology include: great flexibility in forming; programmability; control of the vertical, radial, and rotary motions; and the real-time feedback of the forming process parameters. Moreover, this technology can significantly reduce cycle times compared to conventional, mechanical solutions that may require multiple forming steps and machines to produce a finished part.”