Surrey-based

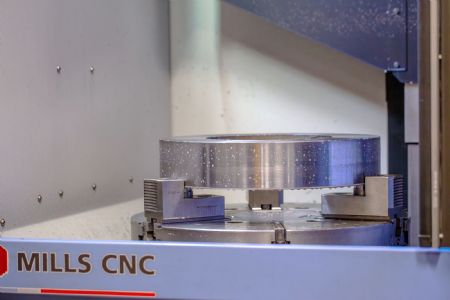

JBJ Techniques Ltd, a leading mechanical and fluid power transmission specialist, recently traded in a 12-year-old Doosan VT750M vertical turning lathe (VTL) for a new, larger-capacity and more powerful Fanuc-controlled DN Solutions’ Puma V8300M with 24in chuck to increase its in-house machining capacity and capabilities. Supplied by Leamington Spa-based

Mills CNC, the exclusive distributor of DN Solutions’ and Zayer machine tools in the UK and Ireland, the new machine was installed at JBJ’s 7,200ft

2 facility in Redhill in January.

The Puma V8300M, with its compact footprint and box guideway construction, is equipped with a powerful, high-torque spindle (30kW 2000rev/min 153Nm making it ideal for machining hard and difficult-to-machine materials and for heavy-duty turning operations.

The new machine also has driven tooling capabilities 18.5kW 4,000rev/min which increases the machine’s flexibility, enabling complex parts to be machined to completion in one set-up without the need for components to be transferred between machines. Furthermore, the integration of a 12-tool position, side-mounted ATC, in addition to its existing 12-tool station turret, increases the machine’s productivity potential by reducing downtime caused by tool change operations.

Fast and flexibleBen Stubberfield, JBJ Techniques’ works director, said: “Our new V8300M is a fast and flexible machine and, as intended, has significantly increased and improved our in-house vertical turning capacity and capabilities. The new machine has replaced a previously-acquired VT750M vertical lathe which, although being a good machine that had served us well over the last 12 years, didn’t have a big enough turning diameter to machine some of our larger components.

“This resulted in us having to use an older, and much slower, lathe for these applications which, on occasion, affected our process efficiencies and lead time fulfilment.”

With its reputation built on quality, service and speed of response jbj Techniques, as part of its company-wide continuous improvement programme decided, back in 2023, to replace the VT750M with a new vertical turning lathe with a larger turning diameter.”

He continued: “We approached Mills CNC with our requirements and were introduced to the new DN Solutions’ V8300 Series which, as well as having a bigger working envelope than the VT750M, also featured na additional side-mounted ATC and the advanced Fanuc 0iTP control.”

As a consequence, the company invested in a new, compact Puma V8300M – a machine with live tooling and that, despite its small footprint, features an 830mm turning diameter and 690mm turning height. Since being installed the flexible machine has been put through its paces machining a wide range of components made from a variety of materials that includes stainless steels (304 & 316), super duplex, carbon and alloy steels (EN 8, EN 24), and cast iron.

Parts machined on the V8300M are characterised by their large size and weight and are typically machined in small batches. Component cycle times can often be long, depending on the specific application, and part accuracies and surface finishes, whilst being tight, are not excessively so.

JBJ Techniques, first-established in 1974, is a family-owned business employing 25 people and is a specialist manufacturer and supplier of high-quality products for the mechanical power transmission and fluid power sectors. Originally located in Carshalton, some 15 miles away from its current location, the company first started life as a stocking distributor for a range of other manufacturers’ mechanical and hydraulic power products.

Over the years, following the move in 1984 to its current location, the company has significantly developed and augmented the products and services it provides to a growing number of customers located (primarily) in the UK – many of whom have international operations.

Well-equipped machine shopIn addition to holding a huge selection of products in stock, the company provides customers with a high level of in-house expertise, such as integrating and combining in-depth product knowledge and specification ability with technical consultancy and parts’ manufacture through its well-equipped machine shop, which was first established in 1984 when the company moved to Redhill.

Now in its 50th year and celebrating its anniversary in September 2024, everything that JBJ Techniques provides is underpinned by a range of responsive and customer-focused support services delivered centrally at its Redhill facility and through a UK-wide team of technical sales engineers.

Everything from connection solutions that connect all types of prime mover to any driven component, a complete pump and motor range, cooling equipment, and gearboxes and clutch assemblies can be sourced from the company and can be delivered quickly and efficiently.

JBJ Techniques can assist manufacturers in a number of different ways: assistance in the design of new and/or replacement (application-specific) power transmission systems (from simple to complex, and from standard to customised); next-day delivery on hundreds of products from the company’s well-resourced warehouse; high-quality machined parts and components for bespoke products and systems; and condition monitoring of manufacturers’ existing transmission systems via the AIQ DETECT (for elastomeric couplings) and AIQ CORE (gearboxes) sensor systems.

JBJ Techniques’ managing director Mike Davis said: “Everything we do is geared towards helping customers optimise their production processes. From working in partnership with them to design and develop new mechanical power and/or fluid power systems and solutions through to supplying replacement (stocked or machined) parts for existing systems – our focus is on helping manufacturers avoid/reduce downtime, improve safety and sustainability, and maintain productivity levels.”

JBJ Techniques’ customer base and user profile is large and diverse, and its products and solutions are used extensively in a range of industrial sectors including power generation, oil and gas, renewables, motorsport, food and beverage, transport, environmental, materials handling and marine sectors.

Indeed wherever mechanical power and fluid power transmission systems are employed, there is a good chance that JBJ Techniques’ products, services and solutions have been, or are being, used in some capacity.

Jbj Techniques’ machine shop, comprising seven CNC machine tools and a range of manual machines and equipment, is a vital and integral element of the company’s unique service offering and one that helps differentiate it from its competitors. The latest DN Solutions’ V8300M vertical turning lathe investment has significantly increased the company’s machine shop capabilities and, by doing so, has also helped it improve its ability to respond quickly to customers’ requirements for large and complex high-quality machined components.

The V8300M was installed at JBJ Techniques’ machine shop in January 2024 and a number of company employees have already undergone an intensive three-day machine and CNC/iHMI control familiarisation training programme delivered on-site by staff from Mills CNC’s Training Academy. This will be followed up later (in March 2024) with a further three-day training course at the Academy’s facility in Leamington Spa.