Last month, Brighton-based

C Dugard Ltd announced that it is now the UK sales partner for MYLAS, a well-known Taiwanese machine tool manufacturer, and is introducing the DT Series of twin-spindle twin-turret multi-tasking turning centres to the UK market.

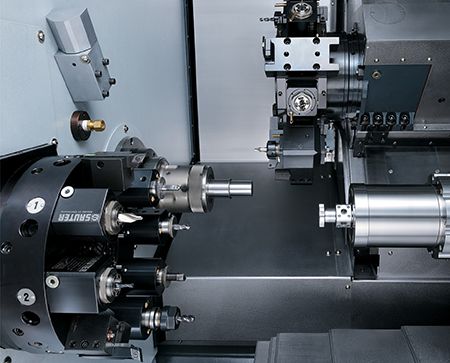

Dugard says that the DT Series of high-end turn/mill centres is ideal for the ‘one hit’ machining of everything from the very simple to the most complex of components. With three machines in the series, the DT42, DT52 and DT65 that all signify the main spindle bar capacity of 42, 52 and 65mm, the MYLAS DT Series demonstrates stability throughout with a stress-relieved Meehanite casting that dampens vibration. Complementing this are over-sized precision ground boxways on all axes and a heavy-duty spindle that generates perfect surface finishes and very fast linear axis movements.

The machines feature twin spindles and twin turrets — the front spindle has a BMT45 12-station turret that can accommodate up to 24 tools. The main spindle generates 7.5/11kW of power and the bi-directional driven tool turret with Fanuc Alpha motors can achieve driven tooling speeds up to 6,000rev/min with 20bar high-pressure coolant and higher pressures to 100bar as an option.

Variety of optionsFor back-working, the DT Series has a VDI 25 eight-station sub-turret and a sub-spindle that can undertake super-imposed machining and make long cycle times a thing of the past.

Furthermore, the sub-turret has a host of options that include a power turret, servo turret or hydraulic turret – emphasising the variety of options available with this class-leading brand. The sub-spindle generates 3.7/5.5kW of power with a 32mm diameter through bore. With a total capacity of up to 32 tools, this multi-tasking turning centre is an advanced machine designed for the precision machining of complex parts in a single setup.

From a specification perspective, the DT42, DT 52 and DT65 have a swing over the saddle of 260mm with a maximum bar turning length of 135 and 150mm on the main spindle with 60mm on the sub-spindle that provides a maximum turning length of 350mm. Axis travel is 175mm on X1/X2 axes with 240mm on the sub-spindle, while Z1/Z2 travel is 450 and 500mm respectively with +/-35mm in the Y axis.

As standard, the MYLAS DT Series is supplied with a Fanuc CNC control, collet chuck, workpiece ejector, 12-station main and eight-station sub turret, auto-lubrication and coolant system, automatic power off and part catcher.

Customers can configure the MYLAS DT Series with options that include live and static toolholders, 5 or 6in power chuck, high-pressure coolant, chip conveyors, oil mist collector, transformer, regulator and a host of CNC control systems.