New additive manufacturing technology — designed and manufactured in the UK — is set to be launched at

TCT 3Sixty today, taking place 5-6 June at the NEC, Birmingham. LANDR, which has been spun out of fast-growing

RYSE 3D, is unlocking engineering-grade technology and materials for SMEs, disruptors and entrepreneurs with the arrival of the new LANDR 500.

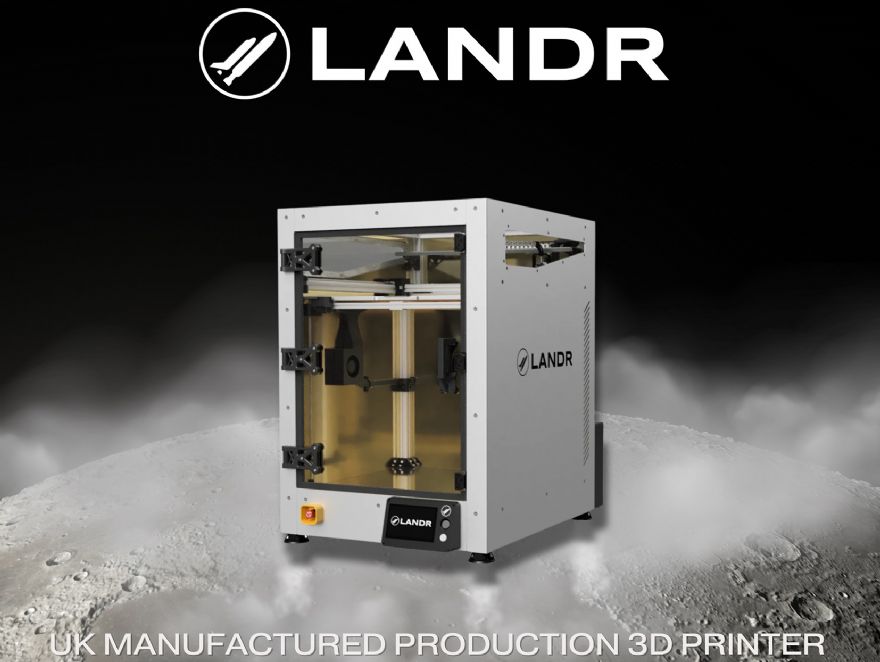

Featuring a large 500 x 500 x 500mm build volume, the large-format FDM printer gives users the scope to build larger and more complex parts and can be applied to rapid prototyping and volume production for end-use in automotive, aerospace, healthcare and consumer sectors.

It is the brainchild of Mitchell Barnes, who recognised the need for a cost-effective 3-D printer that delivered high power and flexible capability. At £11,398.80 (including VAT), its nearest competitor is 10-times the cost, three-times the weight and twice the size, making it difficult to fit into shopfloor operations.

Nearly £200,000 of pre-orders are already in the pipeline and LANDR will use the

TCT 3Sixty event to give potential customers the opportunity to register their interest.

Mr Barnes, CEO and founder of RYSE 3D, which was recently recognised with a King’s Award for Enterprise in the innovation category, said: “I was frustrated with what I was seeing in the marketplace, especially the lack of options that was in our financial reach. Like most difficult things I encounter in life, there is no choice but to take them head on and develop innovative solutions from scratch.”

“Over the course of the next 12 months, the team designed, tested and built LANDR 500, a 3-D printer that will support a wide range of engineering-grade material, delivering strength and durability of large and complex compponents.”

He continued: “This technology is simply not built in the UK, but we knew we had the knowledge and technical expertise to change that notion. It has been a real labour of love, but we have now built and are successfully using 10 printers at our sister business RYSE 3D. With 30,000-plus hours of use so far, there is no better testing ground than a company supplying parts to 18 of the world’s hypercars.”

LANDR, which is based in the Warwickshire town of Shipston-on-Stour, is going to be completing a world first live demonstration of the LANDR 500 on EVO3D’s stand (Hall 1, C20) at TCT 3Sixty.

The 3-D printer offers 100°C heated chamber, 500°C hot end, 140°C bed, speeds of 500mm/sec (even while printing Nylon-CF), Bondtech LGX extruder, double skin gold reflective insulation, built in camera and auto nozzle wipe and nozzle purge, with heated filament dryer coming as standard. A user-friendly, intuitive interface makes it easy to use and accommodates operatives of all experience levels, whilst the full aluminium chassis delivers long-term durability.

Mr Barnes added: “We are excited to offer cutting-edge technology at a price point that makes it accessible to SMEs, tech disruptors, and entrepreneurs. Now, they can enjoy the same level of precision, quality, and capacity that was once reserved for larger companies.

“The large build volume and print speed enables printing of multiple smaller parts or large components in a single run, improving productivity in the process. It’s versatile, efficient and there will be no material lock, meaning you can use whichever material you choose with it.”

He concluded: “We are hugely proud to be a British manufacturer and are delighted to bring world class additive manufacturing technology - designed and manufactured entirely in the UK - to a global audience.”