Automated machines, collaborative robots, 3-D printing, artificial intelligence (AI) in data-driven process chains – the world of metalworking is changing rapidly. Recognising development trends and maintaining an overview is a challenge, and the crucial question remains how individual companies can make the right choices for themselves and use them profitably.

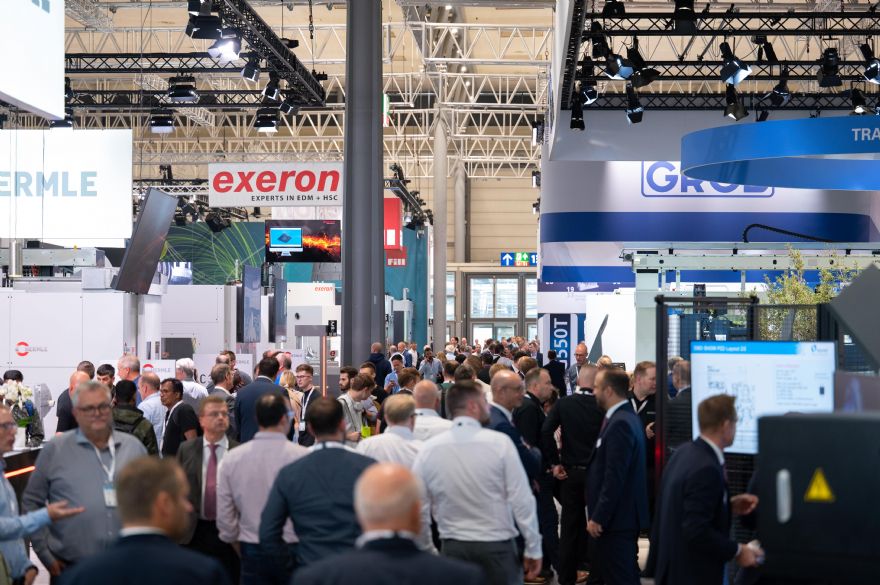

EMO Hannover 2025 from September 22 to 26 will help you to decide.

For Dr Markus Heering, executive director of EMO organiser

VDW (German Machine Tool Builders’ Association),

EMO is much more than just a trade fair. He said: “As a platform for dialogue between all the international players in the industry – manufacturers and users – the trade fair is unique since nowhere else can visitors find so much international expertise as at

EMO.” This will not only be evident at the exhibitors’ stands, but also at the lecture events and forums, as well as at the joint stands with focus topics that are of particular importance for the future of metalworking. There are plenty of opportunities to discuss experiences, network and get to know potential business partners.

There is a need for modernisation in almost every factory or production facility. International competition is forcing companies to search for optimisation potential. Rising costs, energy and raw material prices, as well as the new targets for CO

2 emissions and the circular economy are considered to be the main drivers. Demanding applications such as in aerospace, medical technology or renewable energy require new technical expertise and a higher level of productivity and quality. In addition, the materials that are being processed are changing. High-performance or coated materials become thinner and lighter, stronger and more durable, and more resistant to corrosion and heat.

Overcoming skills shortagesProcessing requires more specialist knowledge, which makes looking at digital solutions and AI particularly worthwhile in times of increasing skills shortages.

EMO Hannover will present possible solutions. Decision-makers can build on the experience of exhibitors and experts to reduce investment risks. Regardless of whether companies manufacture components for the production of diagnostic devices in medical technology or complex geometries for flight-critical parts in aviation, investments in production lines, robot technology or software can only pay for themselves if they increase productivity or open up new areas of business. This is all the more reliable if partners along the value chain can be found and cooperate with each other.

The VDW cites automation, sustainability, digitalisation and AI as the most important development trends in metalworking. Dr Heering added: “Against the background of high-quality requirements and the shortage of skilled workers, automation is vitally important.” Automated production should be easy to operate and flexibly adaptable to the individual needs of the user. It must enable both series production and economical single-piece production.

Automation extends from simple solutions such as pallet changers and handling systems through to the use of robots and autonomous systems. The Cobot Area joint stand at

EMO is explicitly dedicated to the potential uses and applications of collaborative robots.

On the one hand, sustainability is about the measures that can be taken to reduce the energy and material consumption of machines and any secondary and downstream processes. But it is also about the overall contribution that machines can make to CO

2 reduction and sustainable industrial production.

Bertram Kawlath, president of the

VDMA (German Engineering Federation) in a recent interview, said: “Mechanical engineering is an enabler of the climate-friendly transformation.” The Sustainability Area at

EMO 2025 is a meeting place to experience modern solutions for sustainable production. Exhibitors will provide information on how production can be trimmed for energy efficiency and how renewable energies, the circular economy and life cycle concepts can be integrated.

Digital solutions relating to the IoT (Internet of things) and AI will play a key role in making production more efficient in the future. More and more machines are being equipped with monitoring systems and sensors as standard to record data. Meanwhile, digitally networked process chains create transparency, and ‘intelligent’ machines can predict whether a failure is imminent and enable predictive maintenance.

To find out more about the technologies and innovations exhibitors will be promoting at this year’s show, visit the

EMO website

here.