Dürr, GROB and Manz present the concept factory of a complete ‘made in Europe’ battery production plant at the Battery Show Europe

Dürr, GROB and Manz present the concept factory of a complete ‘made in Europe’ battery production plant at the Battery Show EuropeIn 2022,

Dürr,

GROB, and

Manz formed the first European partnership in lithium-ion battery production technology. Their goal is to become a leading European supplier of complete battery production systems. This year, the three companies are showcasing their jointly developed concept factory at

The Battery Show Europe, which is taking place 18-20 June in Stuttgart (Hall 10, Stand H40). The factory highlights end-to-end process automation, perfectly coordinated interfaces, and integrated, holistic digitalisation solutions.

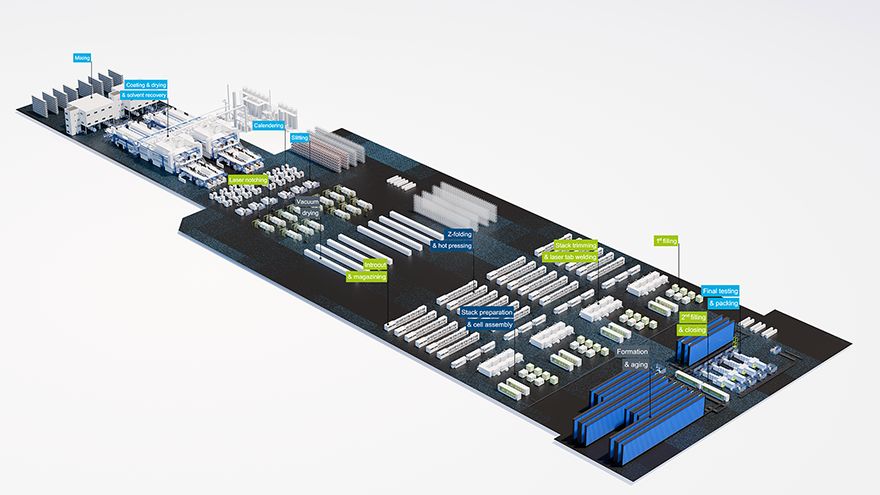

The three companies possess most of the necessary machinery and plant technology to cover the entire process chain from electrode production to cell assembly and from module to pack assembly. Since the partnership began, they have focused on developing a concept factory for battery production. In six defined workstreams, particular emphasis was placed on achieving above-average process efficiency during the planning phase.

Both technical and digital interfaces between the three partners are crucial to development. Dürr’s subsidiary iTAC, an expert in process digitalisation, contributes its MES/MOM solution, enabling end-to-end visibility of all battery production steps. This includes control and planning of the entire production process, as well as analysis and traceability. The result is high overall system efficiency and lower operating costs, primarily achieved through reduced energy consumption and a smaller overall plant footprint.

The first joint customer project, a system for electrode production and battery cell assembly, is already underway. The single-source approach saves the customers from complex project management, as processing interfaces have been streamlined. Dürr, GROB, and Manz offer smooth implementation following proven project management standards and have an extensive supplier network at their disposal.

Developing a competitive battery industry in Europe requires more than just political incentives and guidelines. Quality and cost requirements, along with ecological goals, are equally crucial. Full integration of machinery and equipment manufacturers’ expertise in engineering and project management is essential to ensure competitiveness for cost, quality, and speed.