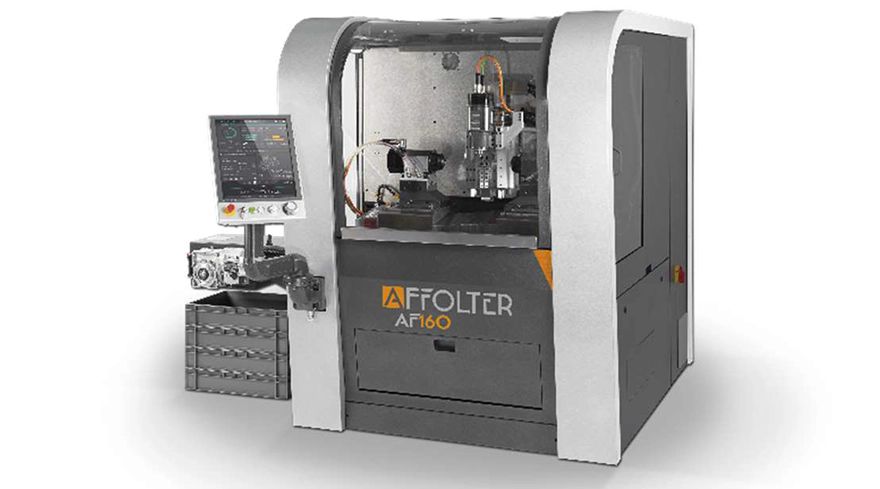

Eight independent axes make the AF160 the most versatile Affolter gear hobbing centre on the market. Photo: Affolter Group SA

Eight independent axes make the AF160 the most versatile Affolter gear hobbing centre on the market. Photo: Affolter Group SAThe gear hobbing machines and solutions of the Swiss company

Affolter Group are designed for ultimate precision, productivity and versatility. Mikaël Affolter, head of sales of the family-owned business, said: “Maximising flexibility is in our DNA. A core advantage for our customers is our in-house software development expertise — our specialists provide tailored and efficient solutions, making our customers more productive.”

While many other machine manufacturers outsource software development, resulting in long and costly development cycles, the in-house engineers at Affolter react to each and every customer request individually and quickly. Mr Affolter continued: “We develop new options and configure each AF160 based on the needs of individual customers.” Such hobbing options include skiving by sensor detection, integrating the deburring process, part orientation, part presence control, and much more.

Mr Affolter explained: “Instead of pre-configuring every detail, we offer an open system that can be tailored to the needs of every customer. We fine-tune the software and the machines to make our customers more productive.” The hardware is provided by our long-term partner

Beckhoff Automation, one of the world’s leading specialists for automation and PC-based control technology.

The 19in HMI touchscreen is very user-friendly and all processes and machine actions are communicated in plain language. The ‘state of the art’ digital Pegasus CNC control ensures extremely fast regulation and integrates IoT. Data can be shared on the cloud, streamlining after-sales service support and preventive maintenance, and therefore minimising downtimes, while software updates can be managed remotely.

The machine itself has eight axes, sophisticated automation solutions, and an innovative quick-change system, which collectively make precision manufacturers more productive and efficient. Operators can switch from one setup to the next in only 30min and three main gear cutting configurations can be selected. The AF160 not only manufactures high-precision spur, helical, bevel, crowned and face gears, but can also be used for worm milling, power skiving of internal gears, as well as the production of ace gears.

Affloter will be exhibiting the innovative AF160 at the

International Manufacturing Technology Show (IMTS) in Chicago, which takes place from 9-14 September. Visitors will be able talk to the experts of Affolter and their US representative

Rotec Tools. The Affolter stand will be in the North Building, Level 3 (stand 237223).