A leading supplier of complex aerospace parts is enhancing the reliability of its machining operations since investing in Vericut verification, simulation and optimisation software from

CGTech. Among many benefits, the implementation of Vericut has seen this progressive manufacturing business reduce its scrap rate for FAI (first article inspection) parts to almost zero.

Established in 1979 and today located at Manisa in the west of Turkey,

HMS Makina is a leading machinist of many different parts and products for a global portfolio of aerospace primes and their sub-tiers, mainly in EU countries. The company, which employs 440 highly skilled personnel, exports 70% of total sales from its modern 23,000m

2 production facility. All of HMS Makina’s special processes carry approvals by major OEMs and NADCAP.

Onur Benzergil, new part supervisor at HMS Makina, said: “With over 80 high-technology CNC machines we were able to produce complex and precision parts from all kinds of light and hard metals, including aluminium, steel alloys, stainless steel, titanium, magnesium and nickel-based superalloys from plate, sheet, castings and forgings in compliance with customer specifications.”

Finished aerospace productsMr Benzergil leads the team that carries out machining process design and NC programming for aerospace parts. HMS Makina has ability to offer finished aerospace products, providing post-machining services that include NDT (non-destructive testing), shot peening, surface treatment, painting and assembly. This market differentiation, alongside its quality-oriented production, makes HMS Makina a preferred supplier to the aerospace sector. The company produces a wide variety of aerospace parts for its customers, including forged titanium engine components and structural airframe parts.

Mr Benzergil stated: “Machining these complex-geometry components requires a simulation program to prevent failure and avoid the expense of scrapping workpieces made from expensive materials. As a result, we decided to make this investment because we see Vericut as superior to other solutions. We had been researching simulation systems for a long time, but Vericut is known to every company working in this sector. Since it was such a critical issue, we did not want to leave anything to chance.”

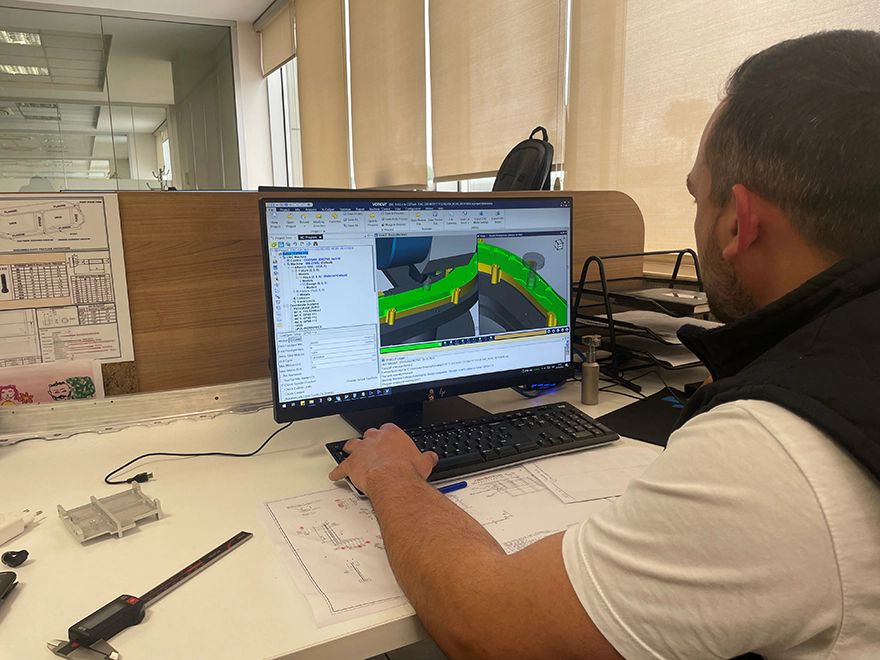

Installed in 2023, HMS Makina leverages the benefits of Vericut to detect errors, potential collisions and areas of inefficiency before actual metal cutting. Innovating and gaining a competitive edge in aerospace means meeting increased demand and tight timelines with high-quality parts. Vericut is the key to machining components quickly and with confidence.

Mr Benzergil continued: “Notably, the software has allowed us to eliminate manual prove-out processes, freeing-up machine time to run more parts. It is also proving highly beneficial in reducing scrap rates. Our scrap rate is now almost zero for first-article parts. In addition, safer machining really stands out for me. Even though this gain is not easy to quantify, I can say safety is the biggest benefit we see on a daily basis.”

HMS Makina also takes advantage of Vericut’s Auto-Diff module at the end of every simulation. The company says Auto-Diff helps it detect errors such as potential gouges, providing approximately 99% accurate results.

Vericut simulationVericut Auto-Diff compares a CAD model with a Vericut simulation, automatically detecting differences, design weaknesses or mistakes in the design. Auto-Diff also reduces the time it takes to prepare an NC tool path. Notably, programmers can check for gouges or excess material while working on the program, identifying and correcting issues before machining.

Mr Benzergil said: “Vericut fully meets our expectations. Today, we do not move to the production phase until the Vericut simulation is complete.”

HMS Makina received comprehensive training and technical support from local Vericut reseller,

Ucgen Yazilimo, every aspect of the software, helping the company to understand the full potential of Vericut.

He continued: “Of course, Vericut should not prove difficult to learn for anyone who uses CAD software. We became familiar with it in a short time period. Today, Vericut is definitely helping us use our machinery more effectively, which in turn drives more efficiency. I think any company machining parts in the aerospace sector should invest in Vericut. The software has a simple interface; so many details are well categorised and it is very easy to access. The graphics are also advanced and I find the ‘Reviewer’ plug-in very useful.”

Vericut Reviewer incorporates all the functionality of NC Review mode in a stand-alone viewer that does not require a licence. The Reviewer can play forward and backward while removing and replacing material. Users can rotate, pan and zoom, just like normal Vericut.

Mr Benzergil concluded: “I would recommend Vericut to other businesses because it has very good infrastructure backed by a great team for technical support. Vericut is a proven and constantly evolving program, and we are finding it highly beneficial here at HMS Makina.”