Since Hove-based

Dugard was announced as the UK distribution and technical partner for the high-end Mylas range of multi-axis turning centres, the popularity of the brand has grown with its suitability in the small to medium-size turned parts segment.

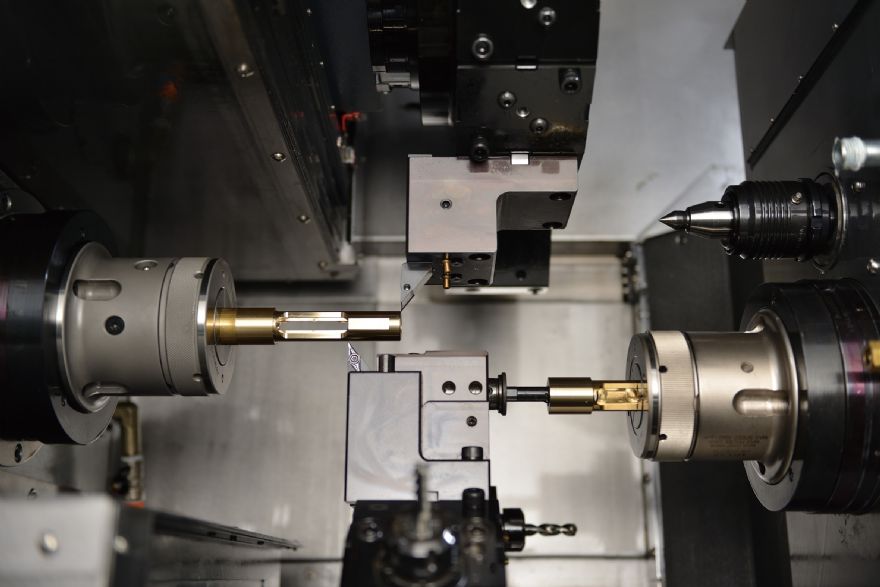

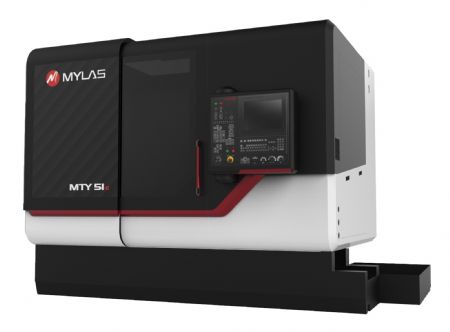

At the top of the Mylas portfolio of multi-spindle multi-axis turn/mill portfolio is the new MTY Series of twin-spindle, twin turret, and triple channel turn/mill centres. Designed to create significant productivity gains, the Mylas MTY range from Dugard can be programmed to simultaneously engage three cutting tools on the workpiece through a range of configuration options.

As a production centre, the MTY Series also has a slant bed monoblock design that evacuates swarf at speed. Incorporated into this robust base are THK double screwnut ballscrews and THK ball guideways with six-piece blocks, a combination that delivers exceptional stability and rigidity while providing the foundation for precise, repeatable heavy-duty machining.

Two versions of the Mylas MTY are available, the MTY 51 and the MTY 65, offering 51 and 65mm bar turning capacity. Within the two models are a series of configurations that can be specified to best meet the needs of the end user. Both the MTY 51A and MTY 65A offer a single Y axis with two tools cutting in tandem, the B type machine offers a single Y-axis, tailstock and two tools in simultaneous cut whereas the MTY 51C and 65C types provide two tools on the part with double Y axis.

Impressive flexibilityMeanwhile, the MTY D is a double channel machine with a double Y-axis and tailstock and the MTY51E and 65E offer three tools in simultaneous cut with double Y axis and tailstock. The impressive flexibility means that Dugard has the optimal solution for all turned parts requirements – from the simple to the most complex.

Within these options, Mylas offers a 5,500rev/min main spindle on the MTY51 and 4,000rev/min on the MTY65 with a power rating of 7.5/11kW plus NN bearing type and roller bearings at the front and rear of the spindle to deliver cutting power directly to the cutting surface – resisting axial and radial forces. Complementing this on the sub spindle is a powerful 6,000rev/min unit with 5.5/7.5kW that sits alongside an optional tailstock with 100mm travel to increase turning length up to 5xD.

To offer maximum flexibility, the two BMT55 tooling turrets each provide 16 tool stations with a maximum tool capacity of 64 positions and a powerful live tooling motor of 3.7/5.5kW that rotates up to 6,000rev/min with a tool indexing time of just 0.16sec.

Looking at the overall specifications of the Mylas MTY Series, the machines are provided with a 6 or 8in chuck and a maximum turning diameter of 180mm on the main and sub-spindle with a bar capacity limit on the sub-spindle of 42mm. Where applicable to the individual configuration, machines have axis travel of 186.5, 175, 600, 600, 590 and +/-45mm in the X1, X2, X3, Z1, Z2, Z3, Y1 and Y2 axes with X-axis rapids of 24m/min and 36m/min in the Z axis.

As standard, the new Mylas MTY Series is supplied with a BMT55 16-station turret in positions T1 and T2, fixed toolholder, high-pressure central cooler motor, part catcher, part and chip conveyor, chip cart, Fanuc 31i CNC, THK ballscrew and linear guideways, bar feed interface, air blower, automatic lubrication, coolant system and hydraulic system.