Photos courtesy of Sandvik Coromant

Photos courtesy of Sandvik CoromantIn the intricate world of medical device manufacturing, where precision is paramount and innovation saves lives, a strong production process is critical. From crafting tiny bone screws to fabricating complex hip replacement parts, there is high demand for accuracy, reliability and efficiency.

The medical device industry encompasses a wide variety of products designed to diagnose, monitor and treat medical conditions. From diagnostic equipment to implantable devices, the industry caters to the evolving needs of healthcare professionals and patients worldwide. According to the World Health Organisation (WHO), there are an estimated two million different kinds of medical devices on the global market, categorised into more than 7,000 device groups.

Annika Langéen (pictured right),

Sandvik Coromant’s vice president of offer management and R&D said: “Manufacturing components for medical devices presents unique challenges that demand advanced machining solutions. End users rely on these devices being manufactured to the highest quality, as any products that do not meet quality standards can cause huge disruption. Entire operations could be paused, products recalled, organisational reputation damaged and patients’ lives put at risk.

“Additionally, regulatory requirements are stringent in this field. There are international standards around quality management — such as ISO 13485, risk management and ISO 14971 — as well as regional regulations such as 21 CFR and FDA for the US and EU MDR for the European Union, which all devices must meet. The requirement for such high accuracy means manufacturers cannot risk even a millimetre of differentiation between components, so having a robust machining setup is paramount.”

Machining challengesShe continued: “From a machining perspective, the size and complexity of device components require micron-level precision, so any manufacturing process that is used must offer accurate end products. The materials used for a wide range of medical device components — typically titanium, stainless steel and special alloys — are selected due to their resistance to corrosion and wear, toughness and biocompatibility. But machining such materials to a high degree of precision doesn’t come without its challenges. In particular, they must address issues around tool wear, heat generation during machining and surface finish on the component.”

There is also the issue of productivity. In general, there is an imbalance between the cost development and what the market is willing to pay for in any industry. To bridge that gap, manufacturers must continuously increase efficiency and productivity. Sandvik Coromant estimates that manufacturers waste between 10% to 30% of material in their machining processes, with a typical machining efficiency of below 50%, which includes at the design, planning and cutting phases.

To overcome these challenges, it is essential to partner with specialists that can deliver on specifications required. Metal cutting solutions from Sandvik Coromant are focused on reducing non-cutting time, to ensure maximum productivity. Its tools are designed to be highly flexible, modular and make use of a high-pressure coolant to maximise uptime.

To illustrate Sandvik Coromant’s medical device tool and machine success, let’s take the example of bone screw manufacturing. Bone screws are the most common general purpose fixation devices, with many applications. They may be used alone in reconstruction or reparative surgery, or with other hardware devices, such as plates, to fix them to the bones. Typically, bone screw bars are between 4 and 12mm in diameter and are made of titanium or stainless steel.

Thread whirling

With such a wide array of applications, bone screws typically are long and thin in shape, and manufactured in many different sizes to cater to different body parts. They are generally produced in quantities of between 30 and 1,000 using a technique known as thread whirling — a machining process used to create high-quality, precise threads. A cutting tool is mounted on a rotating spindle, which is fed into the workpiece while it rotates. The cutting tool typically has multiple inserts arranged around its circumference.

During thread whirling, the workpiece rotates on its own axis while also being moved longitudinally along its axis. Meanwhile, the cutting tool rotates around the workpiece, cutting the thread profile into it. This simultaneous rotation of the workpiece and the cutting tool allows for the creation of threads with high accuracy and surface finish, and avoids bending and vibrations. However, challenges to avoid include burr formation in the tip while the thread whirling is underway, thread quality when high feeds are used.

Bone screwsSandvik Coromant machining solutions for sliding head machines use the CoroMill 325 whirling system, a dedicated whirling unit and high-pressure coolant pump with filter. This tool is a thread whirling cutter designed specifically for medical device manufacturing, which produces special thread forms quickly and at high tolerances. With multiple thread whirling inserts and holders available, the machine ensures that bone screws are produced without risk of bending or burr formation.

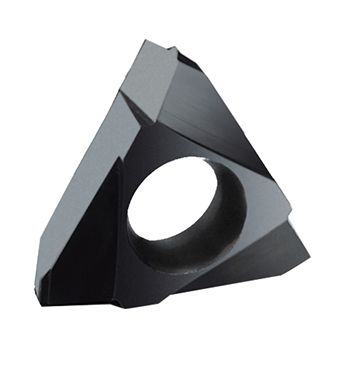

Additional benefits of Sandvik Coromant’s cutting tool solution include increased productivity. The machine completes single-pass machining from stock diameter to reduce the cycle time by minutes and is easily set up to reduce downtime. All Sandvik Coromant thread whirling inserts (pictured right) are available in GC1105 — the first-choice grade for medical machining, increasing tool life and reducing operational costs.

This is just one example of Sandvik Coromant’s medical machining solutions. The metal cutting expert offers a large range of advanced tooling and machining solutions for many additional devices including hip joints, pedicle screws and bone plates.

Annika Langéen concluded: “As the field of medical device manufacturing continues to evolve and become more competitive, driven by advancements in materials, design and manufacturing technologies, precision machining is essential. Partnering with industry leaders like Sandvik Coromant and embracing cutting-edge solutions supports manufacturers to navigate the complex landscape of medical machining with confidence, to advance their innovation and improve patient outcomes.”