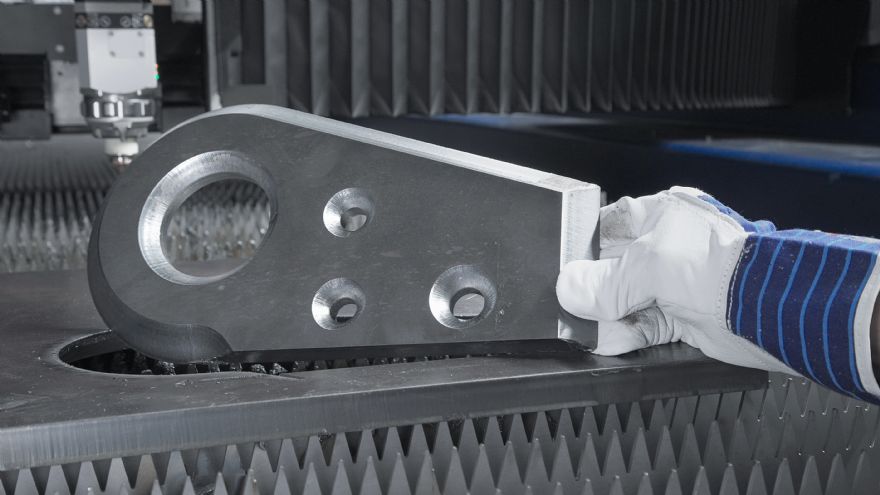

The TruLaser Series 3000 Bevel Cut edition being exhibited at EuroBLECH 2024 by

Trumpf can produce bevelled cutting edges (chamfers) on the top and bottom edge of the component while cutting. This ensures optimum preparation of the welding edges and saves the otherwise necessary downstream work step (Hall 7, Stands B94 and B70).

Patrick Schüle, a Trumpf product manager, said: “With the TruLaser Series 3000 Bevel Cut edition, users get a particularly productive universal machine with which they can integrate downstream process steps into laser machining. This machine can apply chamfers to sheets of up to 25mm thick; and thanks to the design of the cutting unit, the machine can create chamfers of up to 50deg, depending on the sheet thickness, which is more than the 45deg that was previously standard in the industry. The machine can also handle complex bevel geometries with ease and is particularly suitable for mild steel and stainless steel.

“The cutting unit of the TruLaser Series 3000 Bevel Cut Edition has been equipped with two additional rotary axes, particularly compact drive motors, and a nozzle specially developed for bevel cutting, allowing the cutting head to be tilted in all directions up to 50deg; and, as usual, the cutting unit regulates the distance to the sheet, thereby minimising the risk of collision, despite the steep angle. The machine is also equipped with Trumpf collision protection.

“Furthermore, the high flexibility of the cutting unit means it is possible to create bevels in different geometries. In addition to the classic V and Y edges, edge geometries in which both sides of the component edge are provided with bevel cuts, so-called DV and DY edges are also possible; and to meet the high demands placed on the preparation of complex bevel cuts, Trumpf has developed a new intuitive programming system. This contains a preselection of all the processing strategies, which the user can flexibly adapt as required. There are also predefined cutting parameters for the special bevel cut nozzles.”

For the 2-D processing of components without bevels, users still have access to all the proven Trumpf laser-cutting functions, such as Highspeed Eco for reducing gas consumption, FlexLine for the reliable processing of different material grades, and EdgeLine Bevel for the rounding of the upper sheet edges.