Mills CNC

Mills CNC, the exclusive distributor of DN Solutions’ and Zayer machine tools in the UK, and a leading supplier of high-productivity automation solutions for component manufacturers, has announced that its two-day Open House held at the company’s Technology Campus facility in Leamington Spa earlier this month was a big success.

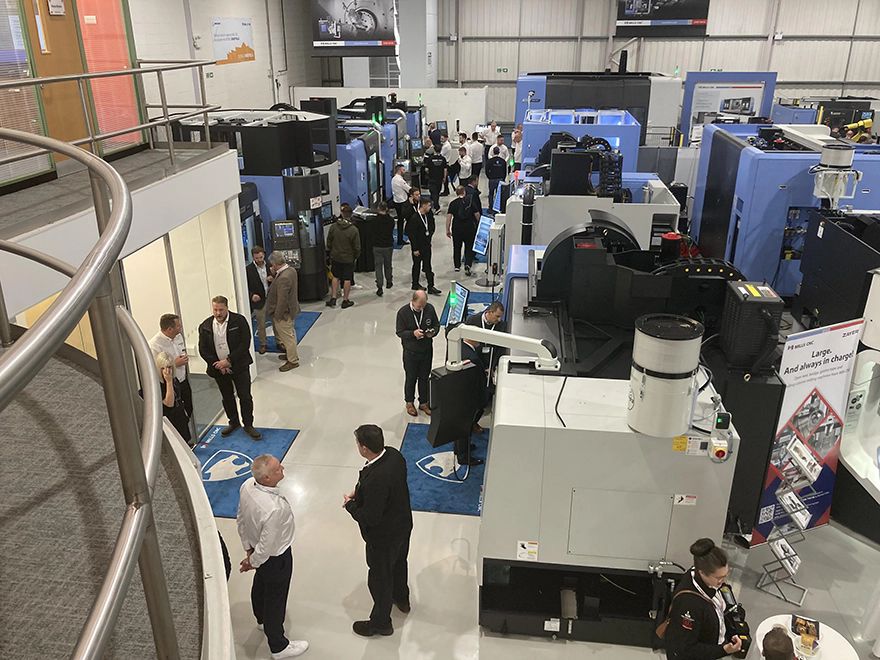

The 300-plus visitors that attended the ‘Pushing the Boundaries’ themed event were able to see first-hand the impressive depth and breadth of DN Solutions’ advanced machine tool ranges, and Mills’ ‘state of the art’ automation systems and solutions.

The 16 machine tools on show included a SMX 2100SB multi-tasking mill-turn machine, two DVF 5000s and a DVF 6500 five-axis machining centres, a TT twin-turret twin-spindle turning centre with dual Y-axis capabilities, a large capacity VT vertical turning lathe plus a number of Lynx and Puma lathes and DNM and BVM machining centres.

A number of the machines on view were integrated with Mills’ industrial and collaborative robot automation systems, with pride of place going to a Synergi Premier automated manufacturing cell and the first showing of a new, multi-level automated pallet-change system.

Tony Dale, Mills CNC’s CEO, said: “We wanted the Open House to appeal to as many component manufacturers as possible — hence the diverse range of machine tool and automation technologies being showcased. All the feedback we have received — during and after the show — is that we got the balance right.”

Mills CNC’s event was dynamic, interactive and demonstration-based with all the machine tools and automation systems showcased under power with many being set up to perform a range of innovative, challenging and industry-relevant machining demonstrations.

Worthy of special mention was the aluminium aircraft door hinge being machined on the DN Solutions’ DVF 6500 five-axis machining centre. This turnkey demonstration, with its emphasis on high-accuracy volumetric removal rates involved the machining of a large 690 x 490 x 120mm solid billet weighing 112kg. After machining operations, which included C-axis rotary milling, five-axis milling and barrel milling, the finished part weighed just 12kg. This demonstration, like many others at the event, highlighted Mills CNC’s extensive, and increasingly sought after, turnkey capabilities and the company’s collaborative approach to solving complex machining challenges.

Mr Dale concluded: “A big shout out to all our technical partners who helped make the Open House such a success and, of course, to all our staff whose hard work and dedication made ‘Pushing the Boundaries’ an event to remember.

“Special thanks also goes to

McLaren Racing Ltd for the loan of a McLaren F1 car (pictured), and to the hundreds of visitors who took time out from their busy schedules to attend the event.”