Based in Silverstone, a short walk from the world-famous race circuit,

Alitech Precision Ltd is a sub-contract design, concept delivery and manufacturing company that specialises in the motorsport industry. To serve this demanding ‘fast-turnaround’ market, the company has invested in high-end machine tools, CAM software and cutting tools supplied by Sheffield-based

Ceratizit UK & Ireland Ltd.

Alitech Precision was established in 2014 with just a three-axis machining centre and CAM package. As the business quickly evolved, it acquired larger bed machines with fourth-axis rotary units before moving to fully simultaneous five-axis vertical machining centres. Specialising in the design of motorsport solutions and taking concepts through design to manufacture in the shortest possible time, the company works with everything from high-performance road cars to Formula One teams in ‘motorsport valley’ — a cluster of firms based around the Midlands and Oxfordshire.

With high-precision, impeccable quality and lightning-fast turnround times a customer pre-requisite, Alitech Precision demands the same from its suppliers – that is why the company depends on Ceratizit for its cutting tool solutions.

Reflecting on how the company has grown since its inception, Alitech Precision’s managing director Darren Cudd said: “We started with conventional entry-level machines and as we got into five-axis machining, we quickly realised you get what you pay for. We haven’t looked back since we bought our first Hermle machining centre and we now have four with a fifth machine currently on order.”

He continued: “The relationship with Ceratizit is not too different to what we have with our customers. We manufacture parts to a very high level and we need very good tooling to do that, especially some of the more specialised tools like long gun drills and bespoke cutters. We work closely with Neville Frisby, our Ceratizit engineer, and we have an ongoing unofficial competition. If Nev gives me a number regarding machining parameters – I always have to try and beat it. Luckily, we know that our machines are more than capable of doing what he suggests concerning parameters, so we always try to push as hard as we can!”

Excellent tool lifeThe Northamptonshire company machines a diverse range of materials and the Ceratizit team is always on hand to meet any challenge. Mr Cudd continued: “We are on board with a lot of racing teams and this has changed the nature of our machining. For example, our pallet-loaded Hermle C22 UP machine spent 4.5 months straight, just cutting titanium through the winter off-season rush. It has been a fantastic learning curve for us and Nev has been there all the way recommending the right tools. We got dialled-in on speeds and feeds pretty quickly and we are getting excellent tool life, which has been above what we were expecting to see. So, we couldn’t be happier with the tools from Ceratizit.”

As a forward-thinking company in a fast-paced sector, Alitech Precision is happy to sacrifice tool longevity for productivity rates. Mr Cudd added: “Being in the motorsport and F1 industry, parts are often required in less than 24hr, so we are always looking at the bottom line. The hourly rate of the machine is typically more than the cost of the tool that will cut the part. So, it is simple math - if we are going to blow two tools to make a job in 30min instead of 1.5hr, it is a simple equation. However, the quality and longevity of the Ceratizit tools always surpass our expectations.”

Looking at specific cutting tools, Mr Cudd highlighted the performance of the Ceratizit three-flute rippers. He said: “We have some large parts that are roughed on a three-axis before five-axis machining. The roughing cycle was around 4hr and this is now down to less than 1.5hr. This is credit to the length of the flute and how hard you can push the Ceratizit rippers. We now find that we are limited by the power of the spindle rather than the tools.”

As a company that operates around the clock, Alitech Precision has invested in a Ceratizit ToolSupply vending solution to ensure that production is always running. Mr Cudd explained: “The vending solution has been a ‘game-changer’. We can be running automated manufacturing on our 18 pallet machine and we may have five or six sister tools for each tool on that job. Even if we pre-order tools on what we think we will need, things don’t always work out as you wish. It is here that the vending machine comes in as a safety net to make sure our machines are always running – its removed tool breakages as a ‘failure mode’ from our business and saved our lives a few times already.”

It is often said in the machining fraternity that Centro-P or ER32 toolholders are not suitable for rough machining, Alitech Precision has not only debunked the myth, but it has taken it a step further — applying Weldon Lock toolholders from Ceratizit to eliminate tool ‘pull-out’. Mr Cudd said: “Traditionally, you look at two factors when roughing a job. Firstly, can the spindle turn the tool, and secondly, will the tool take the stress before it breaks?

We found the limits on both of those factors. We were pushing so hard that a third concern arose — are you pulling the tool out of the collet during machining? Centro-Ps are fantastic but when you lean on them as hard as we do, even they can pull out of the machine. To overcome this challenge, Nev recommended the Ceratizit Weldon shank collets. They drop straight into the Centro-P, lock onto the Weldon shank and we have achieved some pretty ludicrous numbers on how hard we can rough machine jobs without ever pulling a tool out of the collet.”

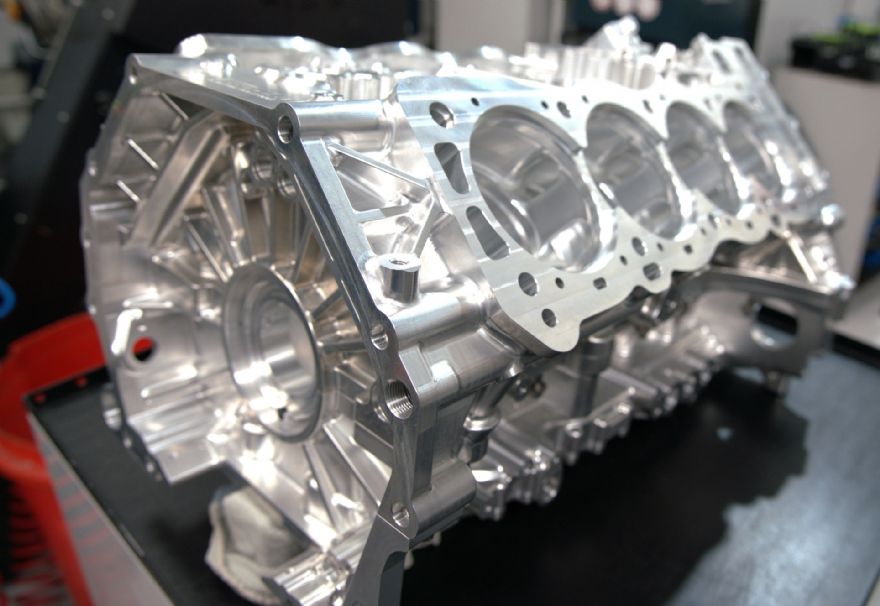

“We also use the Ceratizit shrink-fit system for machining the large complex jobs that other machine shops will shy away from. This includes jobs like engine blocks where we need very long series heat shrink holders to reach ludicrous angles and depths.”

Ceratizit tooling now accounts for 95% of the tooling supplied at Alitech Precision. Recalling the incremental switch from a multitude of suppliers, Mr Cudd said: “Time is money and we are often here six or seven days a week. In the busy seasons, we really don’t have a spare hour to call around cutting tool companies for products and support. The Ceratizit website and app just make it so easy to jump on, find exactly what you want within 2 or 3min, click ‘buy’ and it’ is here the very next day. Ceratizit really is a ‘one-stop-shop’ and we now buy everything from end mills and ball nose cutters to specialist titanium drills, long gun drills, T-slot cutters, collets, shrink fit and much more.”

Ben Philips, Alitech Precision’s sales and production manager, added: “When I joined the company, we were predominantly buying Centric-P’s and heat shrink holders for HSK and BT40 machines, but Ceratizit helped us to diversify from primarily aluminium machining to heavier metals and superalloys.”

Looking to the future, Mr Cudd concluded: “We cannot get another ounce of machinery into our factory, so we have been holding off for the last year or two to try and make a big leap. We will move to a site that will be five-times larger than what we currently have, from 3,500 to 14,000ft

2. As we evolve, our success will be reliant upon the strong relationships we have with both our customers and our supply chain partners like Ceratizit.”