Nikon Metrology NV

Nikon Metrology NV — based in Leuven, Belgium, and a subsidiary of Nikon Corp — has launched Scatter Correction CT. A software solution designed to address the challenges posed by ‘X-ray scatter artifacts’ in industrial computed tomography (CT) scanning, it uses advanced physics-based modelling techniques to significantly improve image clarity and measurement accuracy, particularly for dense materials such as aluminium, steel, ceramic, and Inconel.

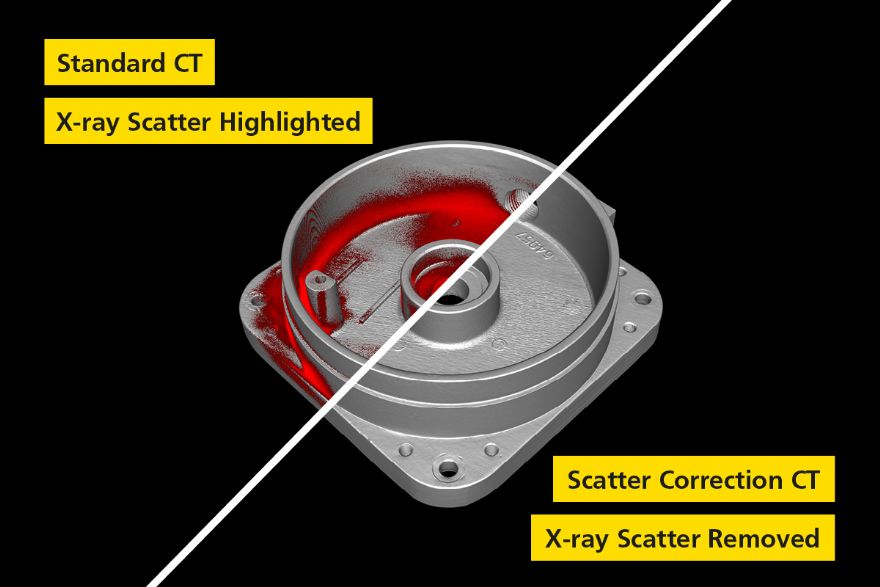

Nikon says: “Scatter Correction CT offers substantial benefits to industries that include aerospace, automotive, additive manufacturing, and castings. X-ray scatter artifacts have long been a significant issue for CT scan operators, hindering their ability to obtain clear images of internal and external structures. X-rays, like visible light, typically travel in straight lines, but are sometimes absorbed and re-emitted, which can change the direction of travel. This issue can manifest as ‘cloudy haloes’ surrounding high-density regions, false inhomogeneities within homogeneous regions, and edge blurring across material boundaries.

“Scatter Correction CT effectively simulates and corrects for these complex interactions, removing the detrimental effects of scatter. Benefits include: enhanced image clarity, thereby enabling more precise visualisation of internal and external structures, defects, and fine details; and improved measurement accuracy, which is critical for quality control and Industry 4.0 manufacturing; scan times that are more than 100-times faster than traditional scatter-free 2-D CT methods, allowing manufacturers to significantly improve throughput and accelerate product development.

Also mentioned is: “Compatibility with all Nikon X-ray sources and systems in the 225kV and above and with all Nikon CT scanning acquisition modes, thereby providing a versatile solution for diverse industrial applications; and ease of use, as the correction is seamlessly integrated into the scanning workflow, requiring only a single click to enable and thereby reducing the need for specialised skills while improving overall productivity.

Andrew Mathers, Nikon’s X-ray and CT global product manager, added: “We are excited to introduce Scatter Correction CT, a game-changing solution that addresses a critical challenge in industrial CT scanning. By correcting for X-ray scatter artifacts, our software provides manufacturers with significantly better image quality and measurement accuracy in their CT scans, ultimately enhancing quality control, product development, and research capabilities.”