Bromsgrove-based

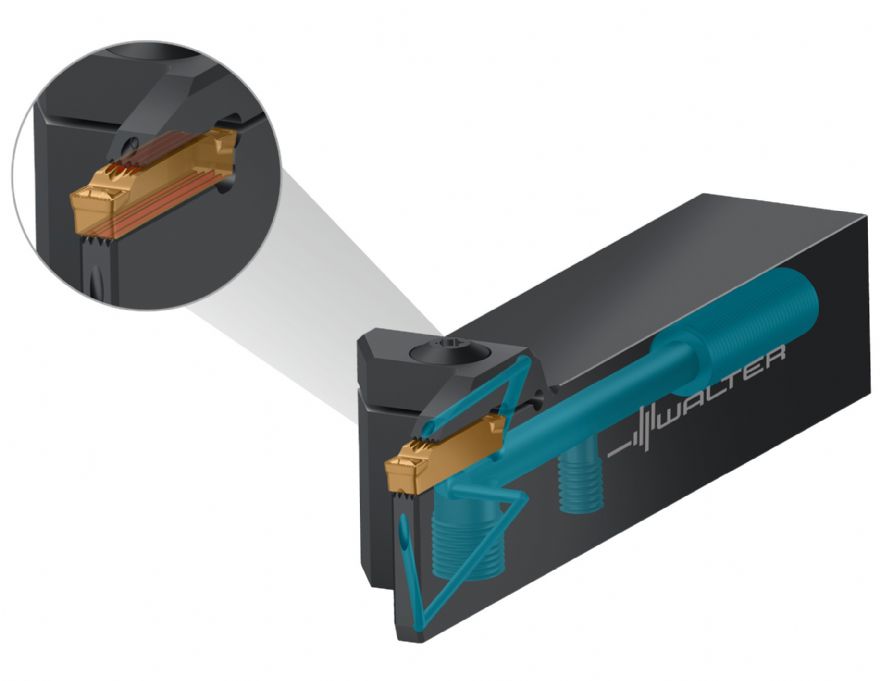

Walter GB Ltd, now offers a new platform for parting off, grooving, copy turning and groove turning with its new Groov·tec GD 5011-P grooving system and the GD26 cutting inserts. The system, consisting of toolholder and two-edged indexable inserts, is characterised by a patented double-serration profile.

The innovative serration profile ensures an extremely stable, positive-locking connection between the robust tool body and the indexable insert. This connection reliably absorbs lateral forces and prevents the cutting insert from being pushed out to the side. This is particularly beneficial when groove turning, widening grooves, chamfering, copy turning and parting off. The precision-fit serration between the cutting insert and toolholder not only provides maximum stability and minimises wear, but it also achieves a longer cutting insert tool life. Furthermore, it extends the service life of the tool support by up to 50%.

Extensive field tests with customers showed that the Groov·tec GD grooving system can be used with significantly higher cutting parameters due to the innovative serration profile and the optional precision cooling. This, in turn, increases the throughput and productivity. Walter offers Groov·tec GD in shank sizes from 16 to 25mm (5/8 to 1in) with insert widths from 2.5 to 6mm – for flexible use in a wide application range.

Another special feature is the new Tiger·tec Gold indexable inserts that have been specifically developed for grooving. The four PVD and three CVD grades also play a part in making the system suitable for universal applications in steel, stainless steel, difficult-to-cut materials and cast iron materials. This makes the grooving system ideal for applications where high process reliability and precision are required, such as highly automated production or large batch production runs. That’s not all — manufacturers can benefit from 30 to 150% longer tool life than standard systems with prismatic clamping.