US-based

Air Turbine Technology Inc, a leading manufacturer of revolutionary high-speed turbine products, has highlighted the benefits of its new

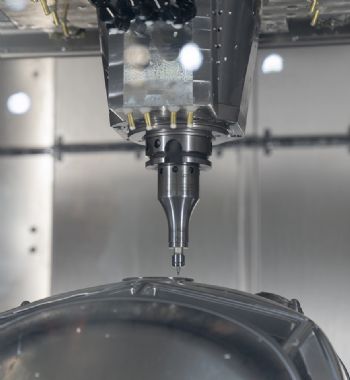

Air Turbine Spindles 601 Series spindle which combines constant high-speed in cut, energy efficiency and a user-friendly design. As a result of its high-speed performance the 601 Series is ‘an invaluable addition in any machine shop to accelerate productivity and reduce costs in today’s fast-paced industrial landscape’.

The compact 601 Series Spindle incorporates Air Turbine Technology’s patented Governor technology, which increases CFM airflow on demand to maintain constant speeds of 40,000 to 90,000rev/min under cutting load on the toolpath through the programme. The 601 Series Spindle provides up to 0.2hp (0.15kW) power, delivering ample power for micro-machining applications — although Air Turbine Technology’s range includes spindles with power to 1.4hp (1kW) for larger tools and hard materials.

This unique governed turbine maintains the required surface feet per minute (SFM) and chip load for micro and small tools by sustaining high revolutions per minute on the toolpath. Cycle times are routinely reduced six to 10-times compared to standard CNC spindles at 6,000rev/min to at most 20,000rev/min. Maintaining high-speed in cut also optimises tool performance, eliminating tool breakage and ensures the production of standardised high-quality parts.

Air Turbine Technology’s direct drive 601 spindle generates no heat, delivering consistent with 2µm accuracy with no thermal growth in the spindle. No maintenance is needed and just two moving parts makes this high-speed spindle reliable.

A connection to 90psi (6.2 bar) air is all that required to make any CNC a high-speed machine. Fully automated loading is available using air supply through the machine spindle, a collar and stop block or manual connection through the side air inlet. Easy installation minimises downtime, allowing manufacturers to quickly adapt to changing production demands.

The high-speed capabilities of the 601 Air Turbine Spindle streamline production by the elimination of secondary operations. Moreover, micro tools are expensive. Big savings result from optimisation of small tool performance and life. Governed high-speed also enhances the overall surface quality of the finished products.

The 50mm extended barrel on the 601 Series reaches into tight workpiece operations allowing greater manoeuverability and access to pockets, angles and hard-to-reach areas. These dimensions enhance access and tool performance on all machines, including those with limited Z-axis travel as well as 360deg five-axis programming. Another great advantage is that the 601 design eliminates the need for long cutting tool stick-out from the spindle collet in angles or pockets causing vibration, tool breakage and poor surface quality.

Precision is paramount in the 601 Series Spindle design. Notably, Air Turbine Spindles generate no heat, ensuring consistent accuracy during extended use. Operation with no heat also eliminates the need for a duty cycle, allowing continuous 24/7 operation without requiring cool-down periods. No lubrication is required in this high-speed turbine — eliminating contamination of parts from misting. This feature is especially important to the medical and food industries. Oil-free operation also reduces maintenance and lubrication costs.

Most popular taper options are available, including HSK-A63, CAT40, BT40, BT30, DIN30, DIN40, and 20mm JS straight shank enabling flexible use with any spindle taper.