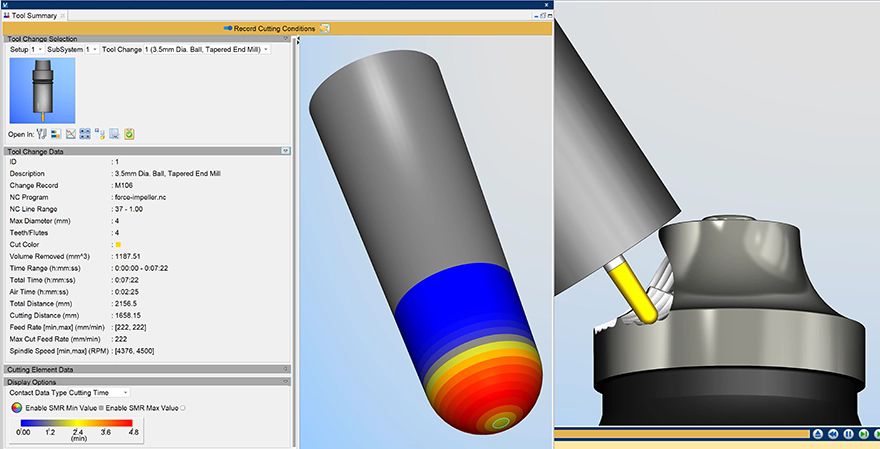

Tool Summary window

Tool Summary windowHove-based

Vericut, the global leader in CNC simulation, verification, optimisation and post-processing software, will be showcasing the latest advancements in its suite of manufacturing software at

Southern Manufacturing and Electronics 2025 which takes place next week, 4-6 February, in Farnborough.

Vericut 9.5 introduces several key enhancements, including a new ‘Heat Map’ in the ‘Tool Summary’ window for visualising tool wear patterns, enabling better tool life tracking. ‘CNC Machine Connectivity’ allows real-time data visibility and post-machining analysis, with support for connecting to Fanuc, Okuma, Siemens, and Heidenhain-controlled CNC machines. The update also improves coordinate system management with interactive ‘Transform menus’, simplifying object placement. Vericut 9.5 also adds support for the latest CAM versions and enhances CAM interfaces for better automation and advanced tool simulation.

Meanwhile ICAM V25 brings enhanced support for multi-channel mill-turn operations, new optimisation features like ‘SmartCUT’ and ‘SmartPATH’, improved singularity avoidance, and advanced motion optimisation capabilities. It also adds a new CL-oriented look-ahead function, virtual machine enhancements, and integration with GibbsCAM. Additionally, ICAM V25 supports offline license use, offers improved 3-D scene manipulation, and provides online documentation. These updates streamline post-processing, enhance simulation accuracy, and improve overall user experience.

Vericut will also be demonstrating the new standalone NC program optimisation solution, Vericut Optimizer. This focuses on optimising cutting processes to reduce cycle times, improve tool life, and enhance part quality. This product is designed to enhance machining performance while minimising costs, and does not require Vericut Verification to run. This powerful optimisation tool seamlessly integrates with any CAM system’s NC program output, allowing manufacturers to optimise their NC programs with just a few clicks, ensuring compatibility and increased efficiency with standard two-axis, three-axis, or four/five-axis CNC machines.