Mott Corporation technician using AM software

Mott Corporation technician using AM softwareTo help US-based

Mott Corporation increase its design and production capabilities for filtration and flow control components, global engineering technologies company

Renishaw recently supplied the company with a RenAM 500 Flex. This new metal additive manufacturing (AM) machine has enabled Mott Corporation to reduce machine turnaround and setup times, while improving the performance metrics of components.

Mott Corporation specialises in solving filtration and flow control engineering challenges in integrated components, point of use sub-assemblies, and integrated subsystems. It offers an extensive material selection for the most critical operating conditions, such as highly controlled bioreactor environments, semiconductor, chemical processing/refinement, and aerospace applications, and is trusted by many of the world’s largest technical and performance brands.

Historically, Mott Corporation produced components using three compaction methods: axial; isostatic; and rolling. However, there are some geometries these techniques are unable to produce. To expand its capabilities, Mott decided to investigate AM, identifying laser powder bed fusion as the best technique for its needs. The most important consideration for Mott Corporation when choosing a machine was that it had open architecture, to enable the parameter editing that is so essential to research and development work. The organisation therefore approached Renishaw to purchase a RenAM 400.

For added control, the company then upgraded its system to the new RenAM 500 Flex machine. This machine which is configurable with one (500S) or four (500Q) high-powered 500W lasers, and offers automatic or flexible powder and waste handling. The lasers can be used in either modulated or continuous wave regimes, adding an additional level of customisation. Furthermore, it uses the same industry-leading gas flow system, safety, and precision digital optics as the rest of the RenAM 500 series but offers additional flexibility with the ability to swap the metal powder feedstock in a short amount of time. Incorporating the RenAM 500 Flex reduced machine turnaround and setup times by over 50%, while improving the standard deviation of performance metrics by approximately 30% in certain cases.

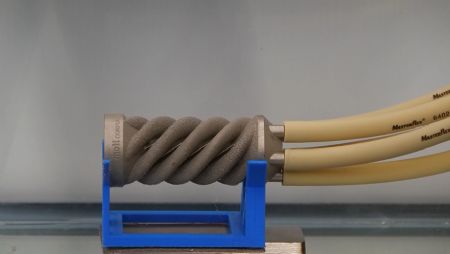

Pictured right: AM filtration component

Pictured right: AM filtration componentJohn Laureto, Americas business manager at Renishaw, said: “Renishaw’s philosophy is that process parameters should be as customisable as possible. Using the RenAM 500 Flex, Mott Corporation was able to optimise its processes for specific applications and can tweak the parameters as needed for novel projects.”

Vincent Palumbo, programme manager at Mott Corporation, explained: “Our ethos is to combine our design, filtration, and flow control expertise with cutting edge technology to create highly engineered products. That is exactly what we are doing here. The new machine gives us greater confidence in the reliability and performance of our parts, while speeding up development cycles, and better enabling us to bring our designs to life.”