FFG

FFG subsidiary MAG IAS GmbH (MAG) has secured a significant contract to deliver a highly automated production line for forged railway wheels to Ramkrishna Titagarh Rail Wheels Ltd (RKTR) in India. The double-digit million-euro project is part of the Indian government's ‘Make in India’ initiative, which aims to transform the country into a globally competitive industrial hub.

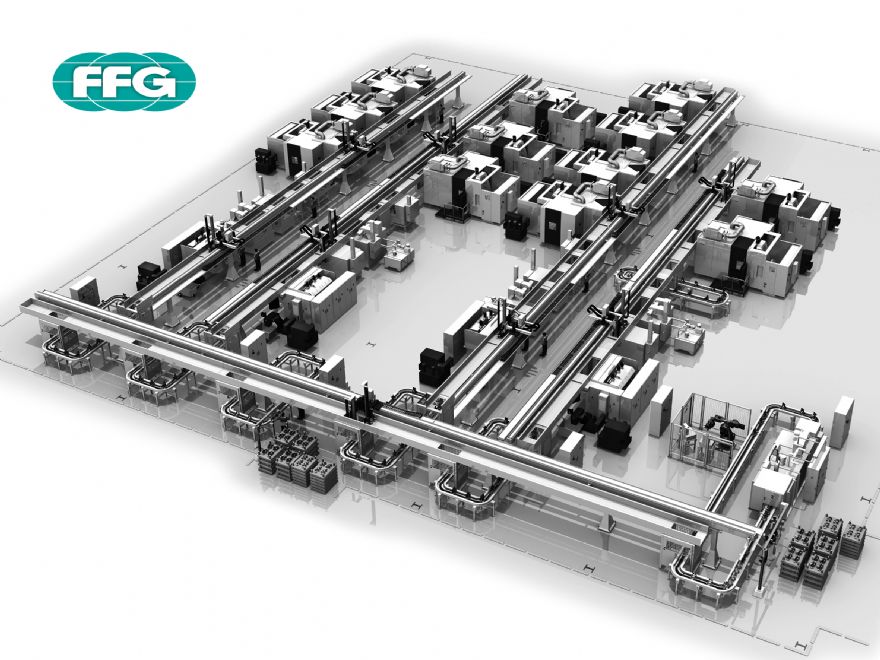

The complete turnkey solution includes advanced machining and testing lines for railway wheel production, featuring equipment from FFG’s MAG and HESSAPP brands, as well as additional turnkey equipment. The ‘state of the art’ system will be installed at RKTR’s Chennai facility and is designed to produce 100,000 railway wheels annually. The system is capable of manufacturing six different types of railway wheels without the need for changeover.

Furthermore, it is designed with future scalability in mind, allowing production capacity to double if needed. To ensure precise planning and fast commissioning, FFG created a digital twin of the system alongside extensive 3-D simulations. The system's pre-calculated energy consumption across various production scenarios supports sustainable manufacturing practices.

The system will feature MAG SPECHT 800 HMCs and HESSAPP VDM 1600 vertical lathes, coolant and chip management for the entire plant, along with automation for both the machining and testing cells, measuring machines, a balancing station, ultrasonic testing units, and two magnetic particle inspection stations.

An outstanding feature of the centrally controlled production system is the seamless monitoring of the entire system and precise tracking of the components, ensuring the highest-quality standards for the manufactured wheels.

Shashank MP, MAG IAS India Ltd managing director, said: “The combination of cutting-edge German technology and local production in India will enable RKTR to meet the demands of the Indian railway sector while adhering to international standards. FFG is a leading solution provider of turnkey manufacturing systems for railway wheel machining, with several projects already installed around the world.”

FFG CEO Dr Sebastian Schöning added: “The award of this contract reflects not only our technological expertise but also our extensive experience, the quality of our machines, and our long-standing presence in India through FFG India. The close collaboration between our teams in Germany and India, along with our deep expertise in turnkey solutions, gave RKTR the confidence to choose us as its partner.”

Production is scheduled to start in the first quarter of 2026, with the system set to manufacture and deliver a total of 1.54 million railway wheels to Indian Railways over the next 20 years. This project supports India’s expanding infrastructure and further strengthens FFG’s presence in the region.