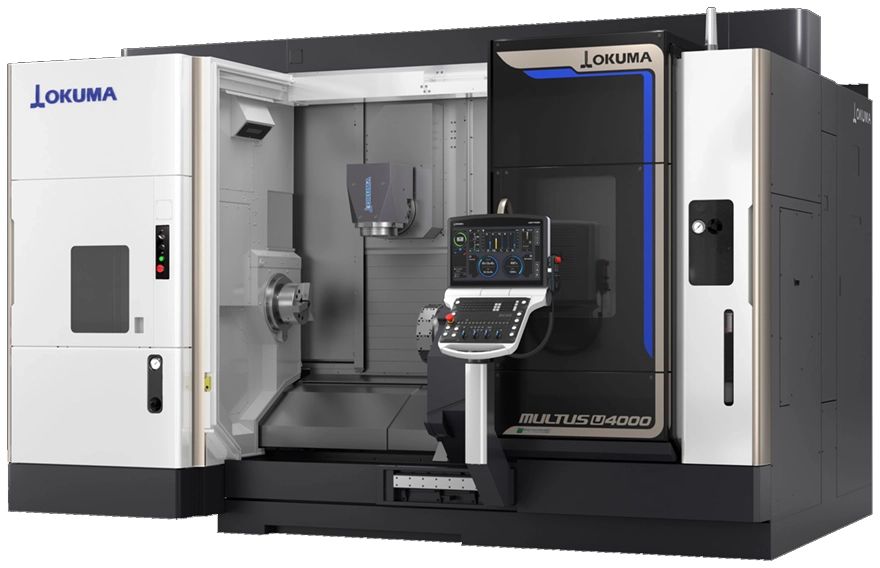

The Multus U series offers a choice of three models with an optional lower turret for increased productivity. Photo: Okuma

The Multus U series offers a choice of three models with an optional lower turret for increased productivity. Photo: OkumaIn 1975,

Okuma introduced its first multi-tasking machine, the LM70-AT, which was capable of turning, drilling and milling in a single unit — a complete machining process. Over the years, Okuma has continued to develop this principle in line with market requirements, and today the Multus range is synonymous with technological innovation and the highest standards.

Multi-tasking machining is to machine tools what the smartphone represents in many people’s everyday lives. Multiple operations, including turning, milling, drilling, threading and other surface processes, can be performed on a single machine with just one set-up.

The benefits for manufacturers are huge: they reduce the number of work steps, minimise the risk of manual errors or material loss thanks to continuous processes, shorten set-up times and require less floor space. Order acceptance has also become more flexible: even urgent jobs can be accommodated quickly, requiring only a program change to the powerful and user-friendly CNC software. The same applies to jobs from new industries or to meet new regulatory requirements: Okuma’s Multitasking Machines enable companies to respond quickly to new requirements. This improves competitiveness, especially for small and medium batch sizes.

The Multus range offers the most advanced Okuma solutions for multi-tasking machining. While the Multus BII series includes various standard models for simple entry-level applications, the Multus B machines are ideal for complex workpieces with diameters of up to 1m and lengths of up to 6m. The Multus U series offers a choice of three models with an optional lower turret for increased productivity. The Multitasking Machines can also be upgraded with Okuma Armroid or robot cells for automation. This increases productivity and efficiency while maintaining the customary user-friendliness and precision machining.

Okuma’s modern machine tools are also increasingly focused on low and sustainable energy use. The Thermo-Friendly Concept compensates for temperature fluctuations and achieves high dimensional stability over long periods of continuous operation. This minimises machine warm-up time, saving energy and costs. ECO Suite Plus adds further energy-saving features. For example, it controls unnecessary pump rotation or the continuous running of decentralised equipment and switches it off if necessary. CO

2 emissions are also recorded.