Stratasys Ltd

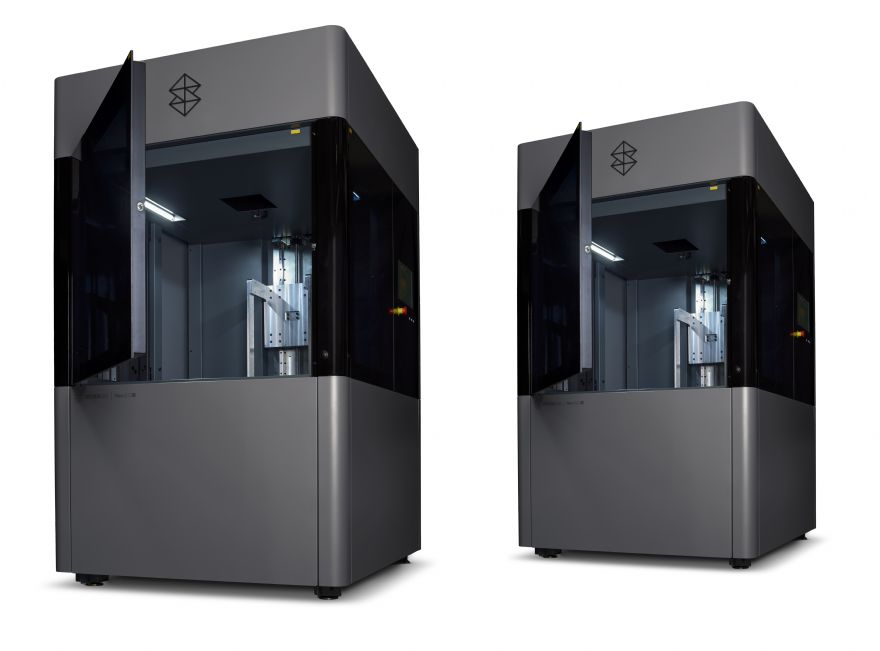

Stratasys Ltd — a global developer and supplier of 3-D printing solutions for industry sectors including aerospace, automotive, consumer products, and healthcare — recently launched its new Neo800+, the latest addition to its stereolithography (SLA) 3-D printer line-up. Compared to the existing Neo800, the new Neo800+ delivers faster 3-D printing speeds, higher part yield, and low production costs — capabilities that ‘address evolving customer needs for uses including wind tunnel testing, prototyping, and tooling’.

Stratasys said: “The Neo800+ incorporates ScanControl+, a scanning technology that boosts printing speeds by up to 50% and enables quicker production without sacrificing precision. The enhanced laser and optics system supports high energy materials, ensuring precision part production with superior surface quality.

“Real-world performance benchmarks have shown that ScanControl+ improves time-to-part by 39% on average and by 44% or more on applications such as tooling moulds, dependent on materials used. Moreover, superior print accuracy minimises post-processing needs, leading to a lower total cost per part.”

Also featured are vacuum system protection, Z-stage collision detection, and real-time environmental monitoring. These features further enhance uptime and consistency, and contribute to ‘greater production efficiency, ensuring reliability for consistent, high quality results’.

The Neo800+ is optimised for ‘ScanControl+ ready materials’ from Somos, and includes Somos WaterShed XC+, a new material engineered specifically for the Neo800+. Based on the widely used Somos WaterShed XC 11122, this ‘next-generation resin’ produces optically clear parts with a smooth finish while enabling much faster scan speeds without compromising on part quality.