Successful trials of Steelpaint’s Combination 500 coating to FRP tanks in Thailand opens the door to numerous industrial applications worldwide

Successful trials of Steelpaint’s Combination 500 coating to FRP tanks in Thailand opens the door to numerous industrial applications worldwideGermany-based

Steelpaint GmbH recently confirmed the successful application and long-term performance of its one-component coating system, Steelpant PU Combination 500, on fibre-reinforced plastic (FRP) and glass flake structures. The trial marks the coating’s first larger-scale industrial application to this class of composite substrate; a material used across many industrial sectors.

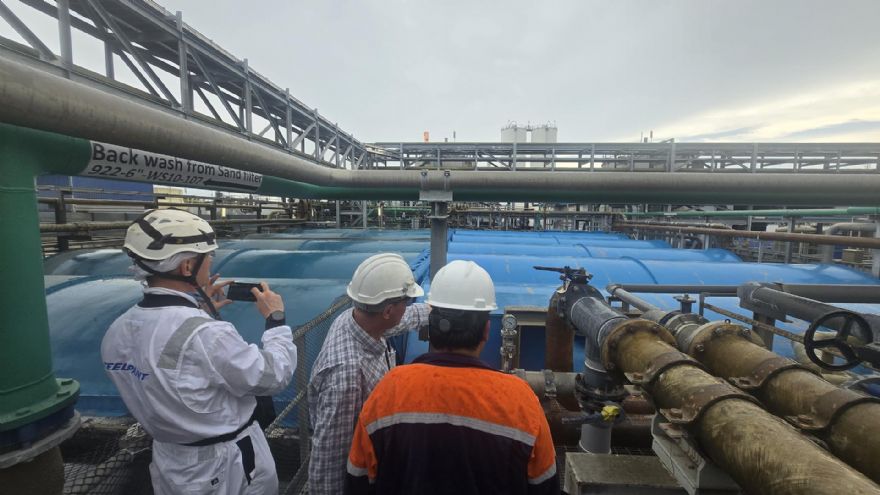

The project, carried out at a large processing and production facility operating in Ban Chang, Thailand, involved the external refurbishment of nine vertical FRP tanks exposed to sunlight, high humidity, and airborne chemical vapours. A 1,250m

2 external surface area was primed with Stelpant PU Combination 500 at 100µm dry film thickness (DFT) followed by a uniform top coat of 100µm, applied by roller, in November 2021. The success of the coating led to a test application in March 2025 on the 840m

2 roof of a similar FRP wastewater tank. This included a 130µm base coat of Stelpant PU Combination 500 with a polyurethane top coat.

According to Dmitry Gromilin, Steelpaint’s chief technical supervisor, the tanks had experienced visible surface deterioration due to prolonged UV exposure in an aggressive industrial environment.

He said: “The glass flake matrix had become brittle and porous, compromising the protective function of the composite surface. Traditionally, such repairs would require a two-component system applied under controlled conditions.”

More streamlined processHe continued: “Our one-component system allowed for a more streamlined process with minimal surface preparation using power tools to remove loose fibre and clean the substrate. By thinning the coating slightly on-site, our partners achieved deep penetration into the fibre matrix, re-sealing exposed glass flake and effectively restoring the integrity of the surface. Combination 500 functions almost like an adhesive, offering mechanical sealing, chemical resistance and substrate protection in a single step.”

Stelpant PU Combination 500 is a high-build, moisture-curing polyurethane coating containing micaceous iron oxide, designed for use on steel, galvanised surfaces, concrete, and now, composite, FRP and glass flake materials.

With dry film thickness recommendations of 100 to 200µm per coat and volume solids around the 64% mark, the coating is designed to protect assets exposed to harsh industrial environments. It is highly resistant to water, UV degradation, and industrial atmosphere, vapours and fumes

Challenging environmentSteelpaint director Frank Müller said: “Combination 500 is tried and tested on hydraulic steel, galvanised metal and concrete structures, but this is the first time we have applied the coating directly to a glass flake structure in that kind of challenging environment. The coating was applied with minimal surface preparation and in less-than-ideal conditions — a humid C5 industrial environment characterised by heavy atmospheric exposure, UV radiation, and caustic emissions from neighbouring facilities — but 3.5 years later, the tanks remain in excellent condition.

“Conventional coatings would require full encapsulation or ideal weather. Combination 500 bypasses all of that. It goes on fast, bonds well to a range of substrates, and cures in the humid conditions synonymous with Southeast Asia and other tropical industrial zones.”

Steelpaint says a universal one-component formulation offers practical and commercial advantages over a two-component system not least because ‘it greatly simplifies logistics and training’ for maintenance contractors. The product is compliant with ISO 12944 C5 requirements and can be used in conjunction with Stelpant PU Zinc primer (for steel and metal structures) and UV-stable top coats where extended durability is required. For structures exposed to direct sunlight, such as the FRP tank roofs, a two-component polyurethane topcoat may be applied to enhance gloss retention and UV stability.

Additional projects using the same coating system on galvanised roof structures and concrete surfaces are underway or already finished and Steelpaint and its partners plan to release further technical guidance to assist infrastructure owners in identifying more suitable applications.