Renishaw

Renishaw, the global engineering technologies company, will demonstrate its latest innovations for process automation, closed-loop process control and rapid part verification at

EMO Hannover 2025 taking place 22-26 September (Stand D06, Hall 5). This includes an innovative new dual-method gauging system and dedicated gauging software.

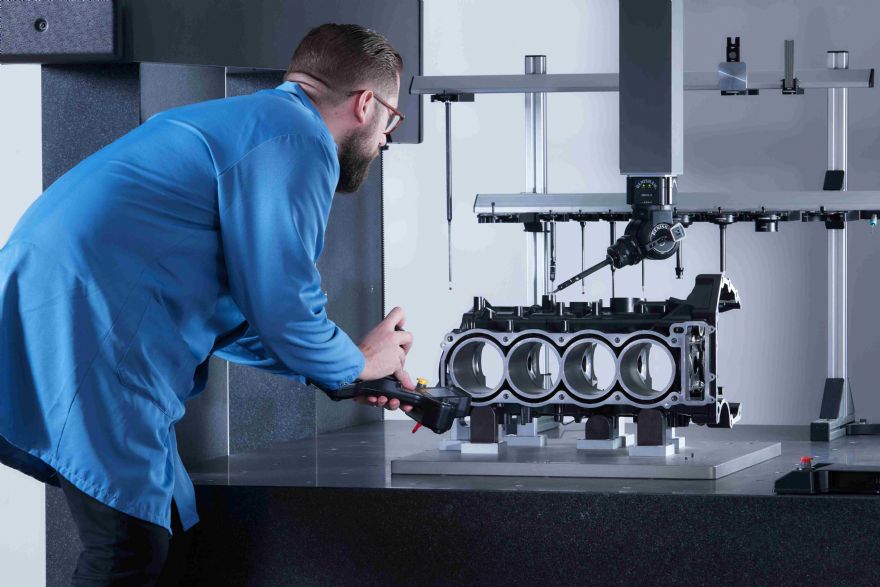

On display will be industrial metrology and automation solutions for CNC machining and process control. All Renishaw technologies provide a level of automation that eliminates the need for human intervention and skilled labour in CNC machining processes. This includes delivering unattended part setup, closed-loop process control, and both machined feature and part verification at the point of manufacture.

Renishaw’s solutions make the integration of robots, metrology, and closed-loop process control for CNC machining easier, faster, and more effective. Taking centre stage will be process automation technologies integrated with commercially available robot-handling systems for CNC machining and closed-loop process control, and automated CMM tending applications.

The company will also highlight its growing range of solutions for enhancing the accuracy and productivity of industrial robots. These technologies provide fast and easy robot setup and robot cell recovery, as well as in-process metrology designed to improve the accuracy of automation cells.

Off-the-shelf integrationVisitors to the stand will also discover Renishaw’s range of products for off-the-shelf integration with automation cells. This includes the new Equator-X 500 dual-method gauge and MODUS IM Equator software, which offer a complete gauging solution for shopfloor processes. The Equator-X system combines Absolute and Compare measurement functionality on a single device. High-performance measurement speed and accuracy also offer significantly improved inspection capacity and throughput compared to conventional three-axis coordinate measuring machines (CMMs).

Supporting this hardware is the MODUS IM Equator software, with code-free programming and reporting capabilities. Rob Harrison, Renishaw’s director of industrial metrology software, said: “The MODUS IM Equator software enhances the Equator gauging system. Empowering our customers to easily create inspection programs, allows them to harness the full potential of our metrology solutions.”

Furthermore, visitors can request a demonstration to experience the software’s ease-of-use and programming first-hand. To expand the functionality of the Equator-X 500 system, Renishaw’s styli and modular fixturing accessories support a wide range of measurement tasks and help maintain high performance across different applications.

New for

EMO Hannover 2025 is the third generation of Renishaw’s range of NC4+ Blue laser tool setters. Offering industry-leading repeatability at ±0.1 μm 2σ, the new ultra-compact F100 models redefine standards for high-speed tool measurement and broken tool detection.

Steve Petersen, marketing manager of Renishaw’s Machine Tool Products division, said: “At Renishaw, we strive to develop technologies that make a meaningful difference to our customers. The new third-generation F100 NC4+ Blue models exemplify this approach, combining sub-micron level precision with a compact, energy-efficient design.”

New smartphone appAnother new innovation for 2025 is a smartphone app, which improves the user experience for Renishaw’s QC20 ballbar. The CARTO Ballbar Connect app makes it quick and easy for operators to complete valuable machine tool performance checks with minimal training. Dave Wall, director and general manager of Renishaw’s Laser Calibration Products Division said: “The CARTO Ballbar Connect app opens up the use of QC20 ballbar to a wider range of users who can now access the benefits of regular ballbar testing.”

Also supporting the reduced complexity of manufacturing is the simple-to-install FORTiS linear encoder. This exceptionally robust technology delivers high-performance measurement in the toughest machine tool environments. FORTiS encoders help to maintain machine accuracy over extended periods, making them ideal for automated 'lights out' manufacturing.

A live demonstration of the Renishaw Central smart manufacturing data platform will connect data from the various measurement devices on the stand, including on-machine measurement, shop floor gauging systems, CMM inspection processes, and sensor data from the company’s leading additive manufacturing systems. With Renishaw Central, issues can be identified, and machining and quality control systems can be updated automatically before the next part is machined, for real-time automated production. The Renishaw Central platform can digitalise, visualise, and act on manufacturing data, and provide greater visibility of parts as they move through the virtual factory.

Rainer Lotz, president of Renishaw’s EMEA region, concluded: “The future of metrology is here. People attend

EMO to witness the best new innovations the industry has to offer, and we are excited to be launching some truly ground-breaking technologies at the show this year.”