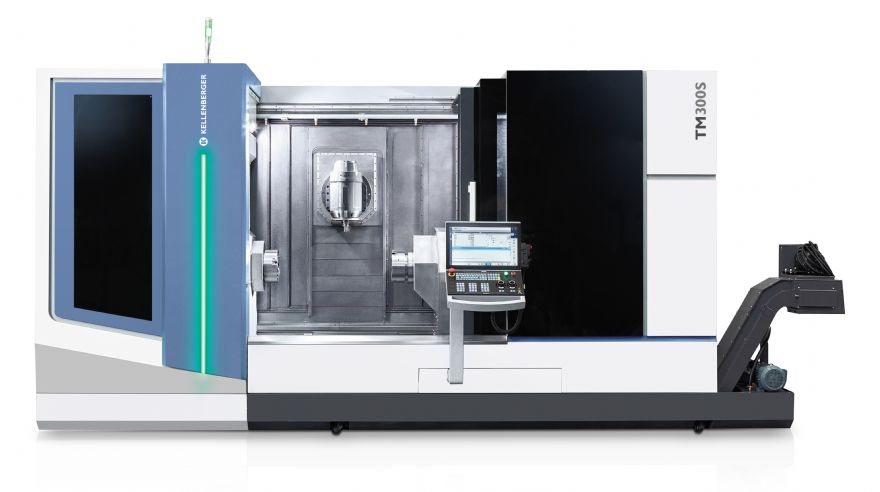

The new Kellenberger TM300 to be unveiled at EMOKellenberger

The new Kellenberger TM300 to be unveiled at EMOKellenberger, the Swiss manufacturer of high-precision grinding machines and systems, is consistently pursuing its growth strategy and expanding its technological footprint. Under the slogan “One name, one brand, endless possibilities,” the well-established brands of Voumard, Hauser, and Tschudin will now operate under the Kellenberger name. In addition, a new machine series will be introduced, expanding the company’s core grinding technology to include turning and milling. The first machine to be developed under this new setup is the Kellenberger TM300, which will be on display at

EMO Hannover 2025, taking place 22-26 September.

New CEO Carsten Liske said: “In the future, we aim to offer Kellenberger customers not only innovative grinding solutions, but also innovative machine concepts in the fields of turning and milling – the kind of solutions Kellenberger has been known for over many decades. With the Kellenberger TM300, we have developed a multi-functional machine for complex machining tasks that demand the highest precision and maximum flexibility. The TM300 complements our successful high-precision SP series machines.”

Kellenberger’s service commitment applies across all series and technologies and includes predictive maintenance, outstanding after-sales support, and comprehensive spare parts availability via the company’s service platform.

The Kellenberger TM300 is a ‘state of the art’ five-axis turning-milling centre which is equipped with a Siemens Sinumerik One control system. The machine is ideally suited for demanding applications in precision engineering, aerospace, medical technology, and general mechanical engineering. The main and counter-spindles offer high performance with 3,500rev/min and 600Nm of torque, while the milling spindle delivers 12,000rev/min and 100Nm of torque.

Enhanced user-friendlinessThe direct-drive B axis offers an extended swivel range of 240deg, and the orthogonal Y-axis with 300mm travel provides a large machining area. User-friendliness is significantly enhanced by the integration of a digital twin, and the TM300 is optionally available with a lower turret, enabling complete machining of complex workpieces in a single setup. For the machining of long shaft components, a hydraulic steady rest is available.

Kellenberger will also be showcasing its core grinding solutions at

EMO. The highly successful Kellenberger K100 universal cylindrical grinding machine (pictured left) is now available with an extended machine bed for workpieces up to 1,700mm in length and a workpiece weight of up to 200kg, with centre height up to 250mm.

This K100 version can also be configured with up to 10 compact grinding head variants to optimally tailor the machine to the parts being processed. The diagonal grinding head arrangement is complemented by a collision-free universal design with a 500mm grinding wheel diameter. Like all Kellenberger grinding machines, the K100 for workpieces up to 1,700mm in length — is equipped with the latest BLUE Solution software, which features the newly developed gSHAPE tool. This part-oriented graphical programming interface enables visual and intuitive creation of machining programs.

Kellenberger is also showcasing its new WHITE Solution CAD/CAM software on the Kellenberger H2000 at EMO, developed in collaboration with software specialist

Open Mind and based on HyperMill. This solution enables even more efficient and precise machining while improving workflow integration. Kellenberger will also highlight the high-end VM1000 universal cylindrical grinding machine, as well as the VM30, which is specifically designed for smaller workpieces and equipped with Rex automation.