BMW Group

BMW Group has announced that its Steyr plant in Austria will begin series production of hydrogen fuel cell systems in 2028, marking a significant expansion of its powertrain manufacturing capabilities. The decision reinforces the company’s commitment to a technology-open strategy, integrating hydrogen alongside electric and combustion drivetrains to meet a broad range of mobility needs. The third-generation fuel cell system, developed in close collaboration with hwww.global.toyota/en Toyota Motor Corporation, introduces major improvements in packaging, performance, and efficiency.

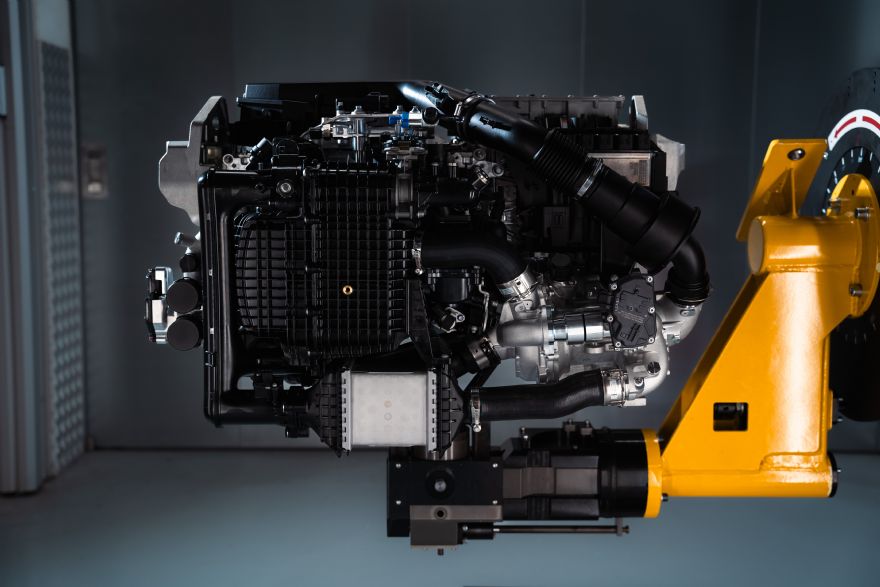

According to BMW, the system is approximately 25% more compact than its predecessor, with a notable increase in power density and energy efficiency, enabling seamless integration into future vehicle platforms. Prototype production is currently underway at BMW’s hydrogen competence centre in Munich, where engineers are focused on validating assembly processes, refining operating strategies, and ensuring the system’s scalability for industrial production.

Joachim Post, Member of the Board of Management of BMW AG (development), said: “The fuel cell system includes not only the stack itself but also the associated cooling, hydrogen, and air subsystems, all of which are being optimised for performance, durability, and safety. Hydrogen fuel cell technology offers a compelling solution for sustainable mobility, particularly in segments where battery-electric solutions face limitations.”

At Plant Steyr, preparations are progressing with the installation of new test rigs, cleanroom environments, and automated assembly systems tailored to the specific requirements of hydrogen fuel cell production. The site, which has long served as a cornerstone of BMW’s engine manufacturing operations, will now play a central role in the company’s hydrogen strategy.

Innovative drive technologyKlaus von Moltke, senior vice president engine production at BMW AG and director of BMW Group Plant Steyr, said: “We are proud to be producing another innovative drive technology at Plant Steyr in future alongside the latest generation of electric motors and combustion engines.”

BMW Group Plant Landshut will manufacture the BMW Energy Master, a hydrogen-specific power control unit designed to manage voltage levels between 400 and 800 volts and serve as the interface between the fuel cell system and the high-voltage battery. Production of the first prototypes is scheduled to begin in mid-2026 at BMW Group Plant Dingolfing, which previously supported development of the Neue Klasse electric vehicle platform.

Landshut will also produce the housing and pressure plate components for the fuel cell stack, continuing its role from the BMW iX5 Hydrogen pilot programme. The collaboration with Toyota remains a key element of BMW’s hydrogen programme. While the first generation of BMW’s hydrogen vehicles relied entirely on Toyota-supplied systems, the current generation reflects a more integrated partnership, with both companies contributing to the development of core technologies while maintaining brand-specific applications. This approach allows for shared efficiencies in procurement and engineering while preserving differentiation in vehicle design and performance.

BMW’s investment in hydrogen fuel cell technology reflects a broader industry trend toward diversified propulsion systems, particularly for long-range and high-performance applications. By anchoring production in Europe and leveraging its existing manufacturing network, BMW is positioning itself to scale hydrogen mobility in parallel with its electric vehicle (EV) programmes. The Steyr facility, with its blend of legacy expertise and forward-looking infrastructure, is set to become a central hub in this transition.