LVD Company nv

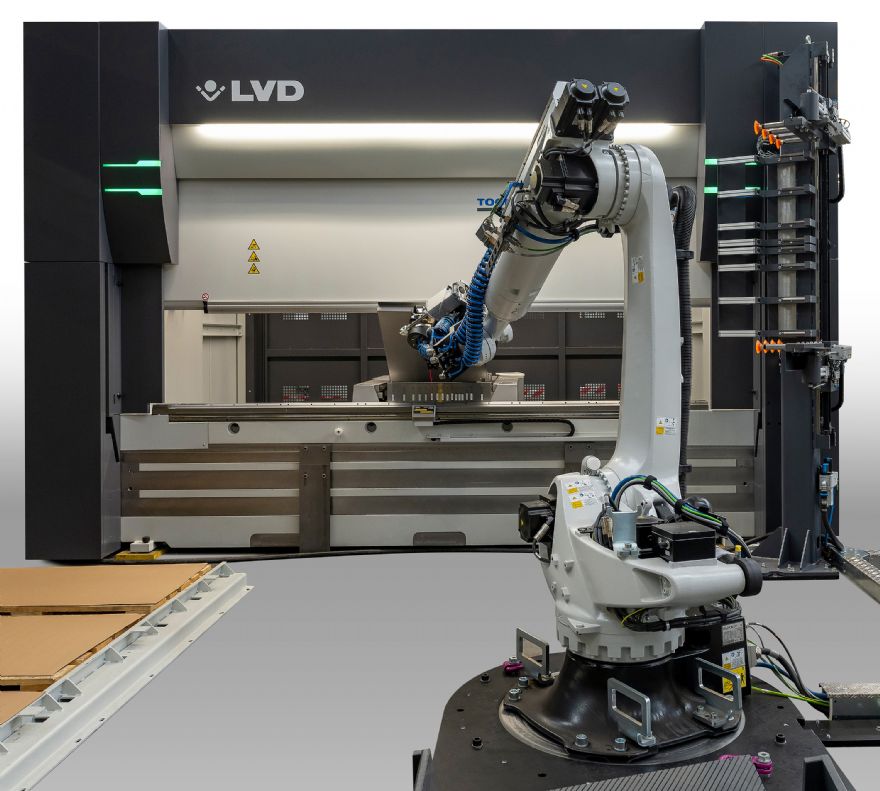

LVD Company nv, a recognised leader in sheet metal-working technology, has introduced a new generation of robotic bending systems (RBS), designed to bring greater flexibility and customisation to automated bending. The RBS range is built on three core platforms, each serving as a foundation for fully tailored bending cells that can be configured to meet the specific needs of individual fabricators.

Rather than offering standardised solutions, LVD’s approach allows users to define key parameters such as press brake capacity, input and output stations, and robot gripper style. This modularity ensures that every RBS cell is optimised for the user’s application and production demands, making bending automation more accessible and delivering faster return on investment.

The three platforms—RBS 4, RBS 40, and RBS 80—are engineered to handle a wide range of part sizes and weights. RBS 4 is suited for small parts, RBS 40 for medium-size components, and RBS 80 for large, heavy-duty applications. Each system is compatible with a selection of press brakes offering varying working lengths and pressing forces, allowing users to match the bending cell to their specific production environment.

Configuration of an RBS cell follows a structured five-step process. It begins with defining the part dimensions, which determine the required robot payload. The next step involves selecting the appropriate press brake, from compact electric-drive models to advanced systems with automatic tool changing. Users then choose the input and output methods that best support material flow, including boxes, pallets, conveyors, and fencing. Gripper selection follows, based on the weight, shape, and material properties of the parts to be handled. Options include universal, manual, magnetic combination, and heavy-duty grippers.

Collision-free operationSoftware integration plays a key role in simplifying operation. LVD’s CADMAN-SIM software automatically programs both the robot and press brake, defining gripper positions and optimising the bending sequence to ensure collision-free operation. No robot teaching or programming experience is required. The system is operated via LVD’s Touch-B control, which provides an intuitive multi-touch interface for both robot and press brake. For added flexibility, the press brake can also be operated manually when automation isn’t needed. An optional Easy-Form Laser adaptive bending system ensures bend angle accuracy from the first bend, supporting consistent quality in automated production.

Peter Vandromme, LVD’s press brake automation sales manager, said: “LVD’s Robotic Bending Systems are designed to meet a wide range of automation goals, whether for short production runs with frequent changeovers or high-volume batches of complex parts. With RBS, we are taking a truly customer-centric approach. Instead of offering off-the-shelf solutions, we configure each cell around the user’s needs — maximising productivity and efficiency. By making bending automation more flexible, we make it more accessible and ultimately more valuable to our customers.”

Alongside the new configurable RBS platforms, LVD continues to offer its standardised robotic bending cells — Dyna-Cell, Easy-Cell, and Ulti-Form—providing fabricators with a comprehensive portfolio of automation solutions.