US-based

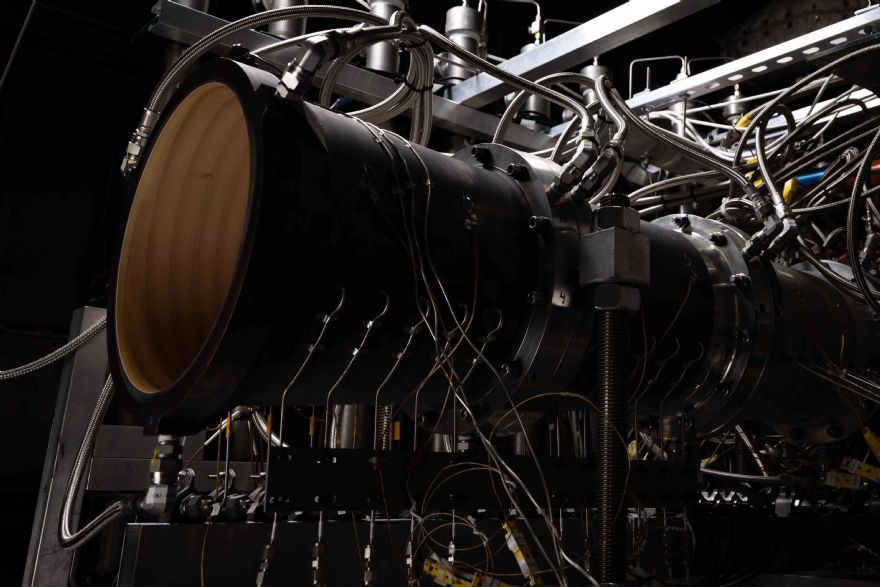

GE Aerospace has successfully demonstrated two distinct rotating detonation combustion (RDC) engines at its Aerospace Research Center in Niskayuna, New York — a missile-scale ramjet and a dual-mode ramjet for high-speed aircraft. This achievement — which could enable high-speed flight and extended range across numerous multi-mission platforms — represents the latest milestone in GE Aerospace’s diverse portfolio of hypersonic propulsion programmes.

The test campaign exceeded expectations, demonstrating robust operation and a threefold (3X) increase in engine airflow compared to previously flight-tested (legacy) hypersonic technology demonstrators.

Mark Rettig, GE Aerospace’s vice president and general manager of Edison Works Business and Technology Development, said: “We have proven that GE Aerospace’s rotating detonation combustion designs are scalable. In just 10 months, our team advanced from its legacy ramjet to a 3X-scale demonstrator with RDC. This rapid progress underscores the maturity of our technology and the strength of our roadmap toward integrated high-speed propulsion solutions.”

Higher thrusts and improved efficiencyRDC enables higher thrust, and improved efficiency at a smaller engine size and weight by combusting fuel and air through detonation waves instead of the traditional deflagration combustion used in ramjets engines today. Testing of the latest engines began in July at GE Aerospace’s continuous flow, high-speed propulsion facility.

The successful development and testing were made possible through collaboration between GE Aerospace engineers, GE Aerospace-Innoveering – a company acquired by GE Aerospace in 2022 specialising in hypersonic propulsion – and the GE Aerospace Research Center. These recent tests also come on the heels of the 2024 testing of a hypersonic dual-mode ramjet that went from concept to test in less than 11 months.

GE Aerospace’s Edison Works is an advanced design, engineering, and technology organisation within the company dedicated to developing the next generation of defence propulsion and systems. With a focus on rapid prototyping, digital engineering, and groundbreaking innovation, Edison Works is where GE Aerospace pushes the boundaries of what is possible to define the future of flight.