Over the past two decades,

Liebherr-Aerospace has established a global network for manufacturing precision landing gear, incorporating 13

Starrag machines to achieve accuracy that rivals nature. A short video from Liebherr-Aerospace captures this ambition perfectly — an eagle lands calmly and precisely on rocky ground, accompanied by the slogan, “The best landing gear is built by nature. But we are working on it.”

The comparison is striking — an eagle weighs just 5kg, dives at 160km/h, and carries only itself. Modern landing gear, by contrast, must reliably support more than 300 tonnes of aircraft weight in all conditions. Together with Starrag, Germany-based Liebherr is committed to producing landing gear systems that operate safely and precisely over time, even under extreme stresses. This philosophy is rooted in Lindenberg in the Allgäu region, a long-standing hub for aviation technology and precision metalworking. Liebherr began here in 1960 with a repair company that evolved into Liebherr-Aerospace Lindenberg GmbH, now a leading global supplier of flight control systems and landing gear.

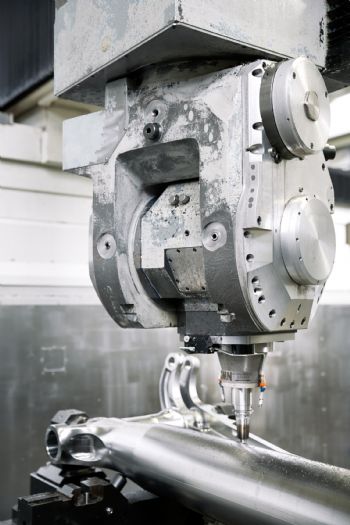

Landing gear components endure some of the highest loads on an aircraft, despite being far less visible than engines or wings. They must absorb the full weight of the aircraft, passengers, luggage, and fuel during every landing, regardless of weather or surface conditions. From the outset, the demands on material, geometry, and production quality have been immense. Over 80% of parts require machining with micron-level tolerances and complex geometries. New landing gear is typically made from high-strength titanium or steel alloys, and machining involves up to 40 steps, including intricate contours, multiple drill holes, and heat treatment.

Lee Scott, director sales and applications for Starrag UK, explained: “As soon as a machining feature protrudes from the cylinder housing, it is no longer possible to rotate in on a turning machine; it has to be milled. It is almost like mould construction — complex external contours, tight tolerances, lots of drilled holes – an all-in-one clamping operation.” To achieve this, Liebherr-Aerospace relies on a high level of vertical integration. Bernd Molinari, group leader in landing gear manufacturing.“We attach great importance to quality and availability. That’s why we manufacture the main components of our landing gear ourselves.”

The partnership began in 2004 when Liebherr opted for its first Droop+Rein FOGS M40, a machine offering exceptional stability, precision, and flexibility. “One of the decisive factors was the similarity of the component geometries to tool and mould construction,” recalled Mr Scott. “The complex contours and drill holes of the landing gear could be machined economically and precisely on the Droop+Rein FOGS in a single clamping operation.”

Between 2004 and 2014, Liebherr built a dynamic production network in Lindenberg around four Droop+Rein FOGS machines, gradually expanding and automating them with robot-supported tool handling, laser measuring systems, and tool magazines for up to 250 tools. Availability was a key priority.

Close cooperationHeiko Quack, sales director for large projects on Starrag’s Droop+Rein product range, said: “Since the first installations, we have been working with a contractually guaranteed technical availability of over 95%. We achieve this through close cooperation — maintenance contracts, regular service workshops, and coordinated planning. Partnership and advanced planning are key to how Liebherr operates the machines.” Remarkably, machines from the early years are still in use.

This production model became a blueprint for Liebherr’s global network. Standardised processes and reliable machines underpin the strategy. After the pandemic-related slowdown, Liebherr resumed its expansion, installing nine additional Droop+Rein machines at partner sites in China, India, France, and until 2022, Russia.

Heidi Quack added: “Liebherr has carefully selected its partners worldwide. Together, we have transferred our technology to these locations – wherever new plants have been built or existing facilities adapted for landing gear manufacturing, we have been involved from the start. Another machine was delivered to Liebherr’s latest partner and began production in 2025.”

Today, Starrag is regarded as the leading machine supplier for landing-gear manufacturing, with around 60 Droop+Rein machining centres in operation globally. Ms Quack continued: “We are the manufacturer of choice in this market segment, not only because of the technology, but also because of our reliable, global partnership.”

Starrag highlighted this collaboration at

EMO 2025 in September with a fully assembled nose landing gear for the

Airbus A350, manufactured at Liebherr-Aerospace. This component represents the largest landing gear Liebherr has ever developed. Since the A350-900 entered service in 2016, Liebherr has supplied systems for all A350 variants, including the redesigned nose landing gear for the A350-1000, which accommodates a higher maximum take-off weight of 308 tonnes. Liebherr’s experience from the A350-900 programme proved invaluable in this development.

The housing of the landing gear is produced on a Droop+Rein FOGS machine in Lindenberg. Though smaller than the main landing gear, the nose gear is critical to safety, enduring heavy loads during take-off and landing and absorbing extreme shocks. High-precision machining not only ensures operational safety but also reduces maintenance costs over the aircraft’s lifecycle.