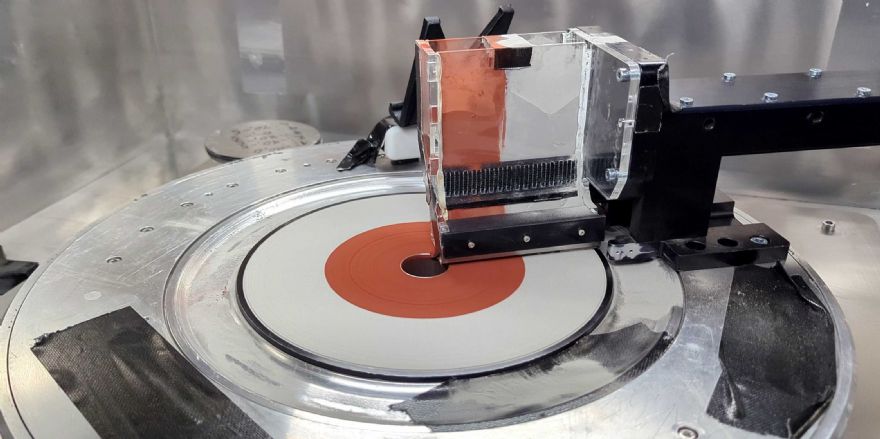

Photo: Michael Tucker/ETH Zurich

Photo: Michael Tucker/ETH ZurichStudents at

ETH Zurich — a public university in Zurich, Switzerland, that focuses primarily on science, technology, engineering, mathematics, and architecture — have developed a ‘laser power bed fusion machine’ that follows a circular tool path to 3-D print round components and enables the processing of multiple metals at once. The system, for which a patent application has been filed, not only significantly reduces manufacturing time but also opens up new possibilities for aerospace and industry.

The team of six students developed the new machine in the Advanced Manufacturing Lab under the guidance of the ETH’s Professor Markus Bambach and Senior Scientist Michael Tucker, as part of the Focus Project Rapture. In a just nine months, the students designed, built and tested their machine, which is particularly aimed at applications in aerospace that feature geometries that are ‘approximately cylindrical’, such as rocket nozzles and turbomachinery, although they say the machine is also applicable to mechanical engineering projects.

Mr Tucker said the project came about from a very specific challenge: developing bi-liquid-fuelled rocket nozzles for ARIS, the Swiss Academic Space Initiative that is building its own rockets with visions of reaching into space. Within the next few years, ARIS aims to reach the Kármán Line — the internationally recognised boundary of space set at an altitude of 100km, beyond which the atmosphere is too thin to support flight by aircraft without special propulsion.”

High-speed 3-D printingHe continued: “In order to withstand the intense heat and pressure over an extended launch, rocket nozzles should ideally be made of multiple metals. For example, their interior can be made of heat-conducting copper with integrated cooling channels and their exterior of a heat-resistant nickel alloy. The heart of the new machine is a rotating platform that enables a high-speed 3-D printing process; but unlike conventional rectilinear laser power bed fusion machines, where a new layer of powder has to be applied after each layer is melted, our Rapture machine works non-stop thanks to its rotating platform.

“This means that powder is applied and fused by the laser simultaneously, which significantly enhances productivity, reducing the manufacturing time for cylindrical components by more than two thirds. Moreover, the rotating machine can process two different metals in a single operation, whereas conventional systems require several steps and a much greater quantity of metal powder.”

As well as application for ARIS and for the aerospace industry in general, the team sees potential applications in other sectors, such as in aircraft and gas turbines, as well as for electric motors where ring-shaped geometries are the norm; and while the components manufactured so far with the prototype have a diameter of up to 20cm, the research team is now looking at scaling the process to higher speeds and larger diameters. They are currently looking for industry partners to collaborate with them.