Boeing

Boeing recently unveiled a ‘3-D printed solar array substrate approach’ that, compared to a typical solar array wing programme for ‘print to final assembly’, shortens composite build times by up to six months — a production improvement of up to 50% when compared to current cycle times.

Michelle Parker, Boeing Space Mission Systems’ vice president, said: “By integrating Boeing’s additive manufacturing (AM) expertise with

Spectrolab’s high-efficiency solar tech and Millennium’s high-rate production line, our Space Mission Systems’ team is turning production speed into a capability that is helping customers field resilient constellations faster.

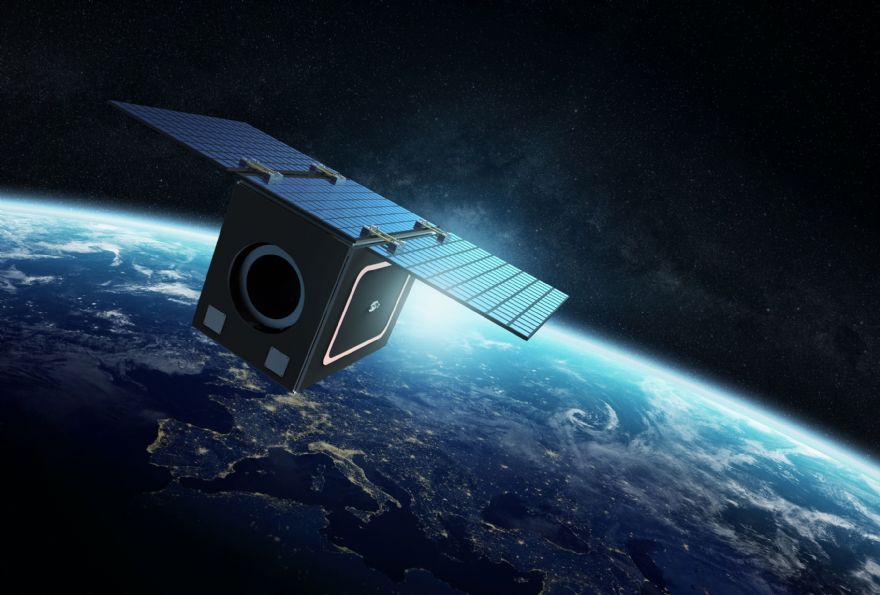

The first 3-D printed solar arrays will fly Spectrolab solar cells aboard small satellites built by

Millennium Space Systems — both non-integrated subsidiaries that are part of Boeing’s Space Mission Systems’ organisation.

“By 3-D printing features such as harness paths and attachment points directly into each panel, the design replaces dozens of separate parts, long-lead tooling, and delicate bonding steps with one strong, precise piece that is faster to build and easier to integrate.”

Melissa Orme, Boeing Technology Innovation’s vice president of materials and structures, added: “As we scale AM across Boeing, we are not just taking time and cost out, we are putting performance in. By pairing qualified materials with a common digital thread and high rate production, we can lighten structures, craft novel designs, and repeat success across programmes.

“The new array approach is designed to scale from small satellites to larger platforms, including Boeing 702 class spacecraft, with the target of market availability for 2026. By printing the panel’s structure and built in features, Boeing can assemble the array in parallel with cell production, while robot assisted assembly and automated inspection at Spectrolab further reduce ‘handoffs’, improving speed and consistency.”