Mills CNC’s

Mills CNC’s recent technology event, ‘The One Show’, held at its Campus facility in Leamington on 15 and 16 October, drew a crowd of over 180 visitors and marked a bold departure from the company’s traditional Open House format. Focused entirely on ‘one-hit’ machining, the event showcased two new DN Solutions multi-tasking and multi-axis machine tools making their UK debut — the DVF 5000 Mk II simultaneous five-axis machining centre and the DNX 2100SB multi-axis mill-turn machine.

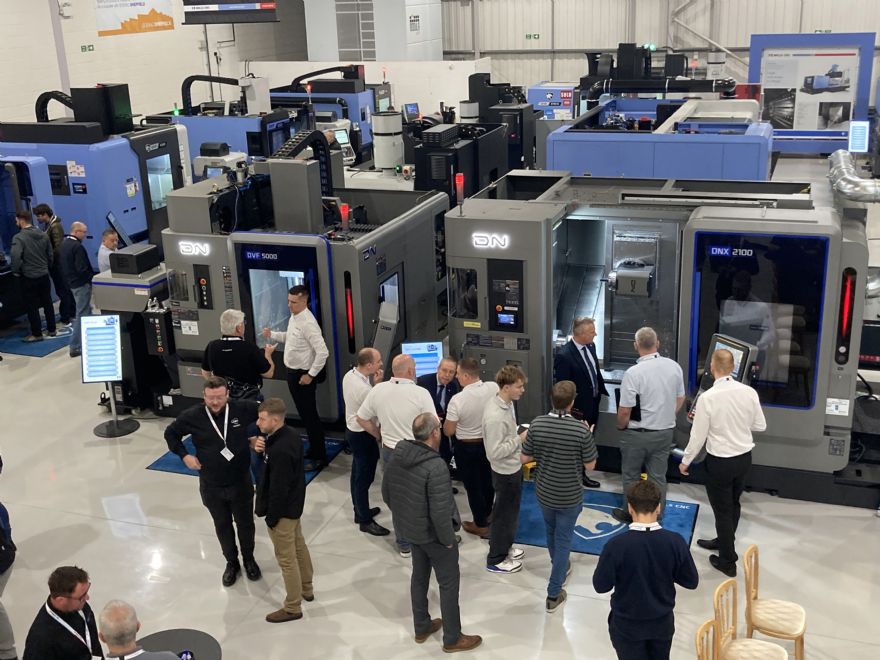

Both machines, presented in striking silver livery, were demonstrated side-by-side, performing demanding machining tasks that highlighted their speed, precision, and flexibility. Visitors were treated to technical presentations delivered by Mills CNC’s pre-sales engineers, offering deeper insights into the machines’ capabilities and how they could enhance productivity and profitability in modern machine shops.

The presentations were framed by a welcome and closing address from Mills CNC CEO Tony Dale, who explained the rationale behind the event’s focused theme. He said: “We wanted to do something different, like no-one else if you like, and, as a consequence, decided to host an event relevant to the future productivity and process efficiency needs of UK and Irish component manufacturers. We focused the whole event around one-hit machining and gave the DNX 2100SB and DVF 5000 MK II machines pride of place at the show.”

While the two new machines were the centrepiece, the event also featured a range of established DN Solutions multi-tasking lathes and machining centres, along with a high-productivity SYNERGi automated manufacturing cell. These additions helped reinforce Mills CNC’s depth of expertise and the breadth of its machine tool and automation portfolio.

“The One Show was a bit of a departure for us, but it has definitely paid off. A number of enquiries for the new DNX 2100SB and DVF 5000 Mk II are being actively followed up as we speak.”