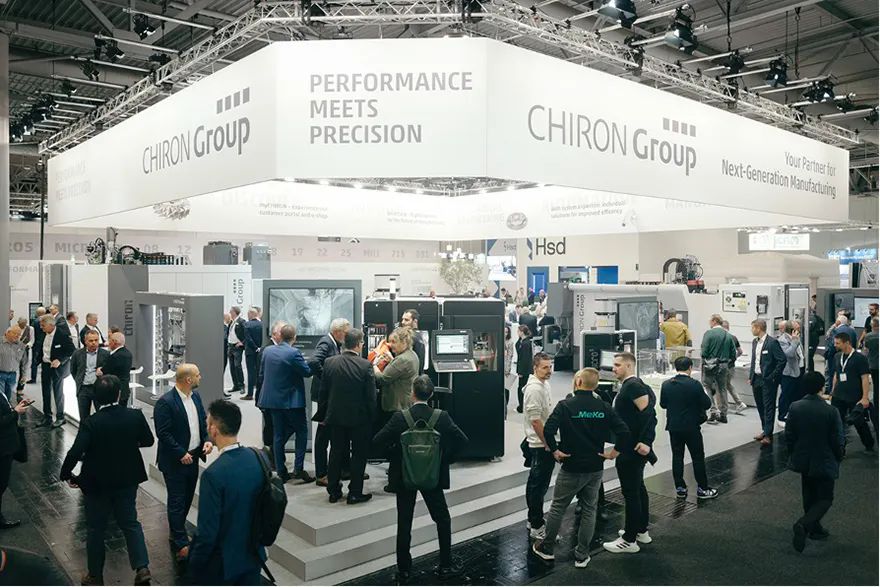

The Chiron Group presented the entire range of modern, efficient production for all target industries in live operationEMO 2025

The Chiron Group presented the entire range of modern, efficient production for all target industries in live operationEMO 2025 welcomed around 80,000 trade visitors from across the globe, all eager to explore the latest developments in production technology. Among the standout exhibitors was the

Chiron Group, which delivered a compelling showcase of four machining centres operating under live cutting conditions within a compact 450m

2 space. The company’s tailored automation solutions and hands-on demonstrations drew strong interest from international decision-makers, marking the event as a resounding success.

Chiron’s presentation offered a comprehensive view of what future-oriented, partnership-based manufacturing can look like. The company covered the full spectrum of modern production — from micromachining for sectors such as medical technology, watchmaking, jewellery and electronics, to the complete machining of complex turbine components for aerospace, as well as high-productivity solutions for automotive and mechanical engineering. Precision, dynamics and process reliability were not just discussed — they were experienced in real-time, with only a handful of exhibitors offering comparable live milling and mill-turn demonstrations.

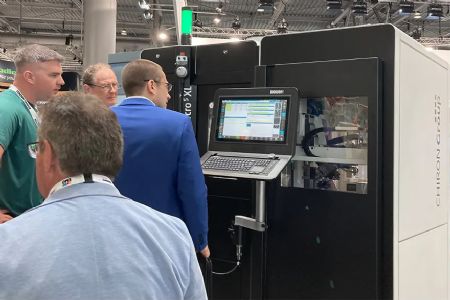

A particular highlight was the world premiere of the Micro5 XL, which made its debut in front of an international audience. The new model represents a significant leap in micromachining, offering increased travel distances, enhanced cutting performance and maximum flexibility. With a footprint

of just 1.7m

2, the Micro5 XL handles workpiece cubatures of up to 120mm and features highly dynamic BC five-axis kinematics, spindle speeds of 40,000 or 50,000rev/min, and jerk values reaching 900m/s

3.

Pictured right: Chiron demonstrated the new Micro5 XL with a Variocell PICK&PLACE automation system

Pictured right: Chiron demonstrated the new Micro5 XL with a Variocell PICK&PLACE automation systemThe machine’s capabilities were demonstrated through the intricate ‘Bone Watch’ part — a watch case and bracelet designed in the style of bone plates. The result was filigree structures, excellent surface finishes and reproducible precision. Supporting the machining process was the new Variocell PICK&PLACE automation system, which fed raw parts into the clamping device and stored finished components. Delivered as a plug-and-play unit, the system includes a pallet trolley with capacity for up to 12 pallets (400 x 300mm, up to 50mm high) and shares the same operating logic as the Micro5 XL. Its front-facing operation and compact design allow multiple units to be placed side-by-side, enabling scalable production.

The Micro5 platform itself continues to set the benchmark in micromachining. Weighing just 550kg and requiring only a 230-volt connection, it can be integrated into virtually any production environment. Despite its small footprint, it offers high static and mechanical rigidity, delivering the precision needed for demanding geometries. At

EMO, the Micro5 produced aerospace-grade connectors live, reinforcing its reputation as the market leader in its class.

Extending the machine’s capabilitiesAlso on display was the DZ 15 W twin-spindle machining centre, paired with the Variocell UNO automation system. Designed for productivity, flexibility and autonomy, the DZ 15 W features a rotary table with direct drive that positions 360deg in under a second — precise, wear-free and backlash-free. Demonstrations included the production of aluminium pump housings for the automotive sector and cast iron fan covers for mechanical engineering. The twin-spindle design allows machining to continue on one side while loading and unloading occurs on the other, enabling parallel processes and continuous part supply — ideal for shift operations. The integrated automation unit ensures short cycle times and high autonomy, extending the machine’s capabilities beyond large-series production.

Pictured left: the FZ 19 S five-axis with open work area and view of the turbine housing completely machined in a continuous process

Pictured left: the FZ 19 S five-axis with open work area and view of the turbine housing completely machined in a continuous process For high-strength materials and demanding applications, Chiron presented the FZ 19 S five-axis machining centre. Designed for aerospace, energy and mechanical engineering sectors, the machine performed all stages of turbine housing production live: rough machining, contour turning, skiving for gear cutting, precision drilling and simultaneous five-axis milling of complex geometries. Its gantry moving portal design ensures high rigidity, while active cooling across all components maintains temperature stability for long machining cycles.

Beyond the machines, Chiron showcased its full range of services in an interactive showroom. Visitors explored the company’s technology portfolio, including reconditioned and available machines — offering a fast, cost-effective route to production modernisation. Experts were on hand to advise on digital solutions such as SmartLine systems, designed to boost efficiency, availability and productivity. The Services division highlighted offerings including spindle repair, machine overhaul, service agreements and the myCHIRON customer portal, which features an e-shop for spare parts and refurbishment solutions — supporting a productive second life for proven machining centres.

Reflecting on the event, Matthias Rapp, vice president global marketing at Chiron Group, said: “

EMO 2025 was a complete success for the Chiron Group. We are very satisfied with the quality of the leads and were able to make valuable new contacts. The great interest shown by international visitors was particularly pleasing — we held many discussions with companies from Asia, North America and Europe. Our innovations such as the Micro5 XL with Automation Variocell PICK&PLACE met with enormous interest and the feedback was consistently positive. The discussions confirmed this: automation and sustainable production remain key topics in the industry — and we are addressing them convincingly.”